Laminated combustion gas transpiration nose cone

A plate-type, nose-cone technology, applied to aircraft parts, fuselage, transportation and packaging, etc., can solve the problems of waste of coolant, heavy gas supply system, large space occupation, etc., to reduce quality, no risk of leakage, save The effect of the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

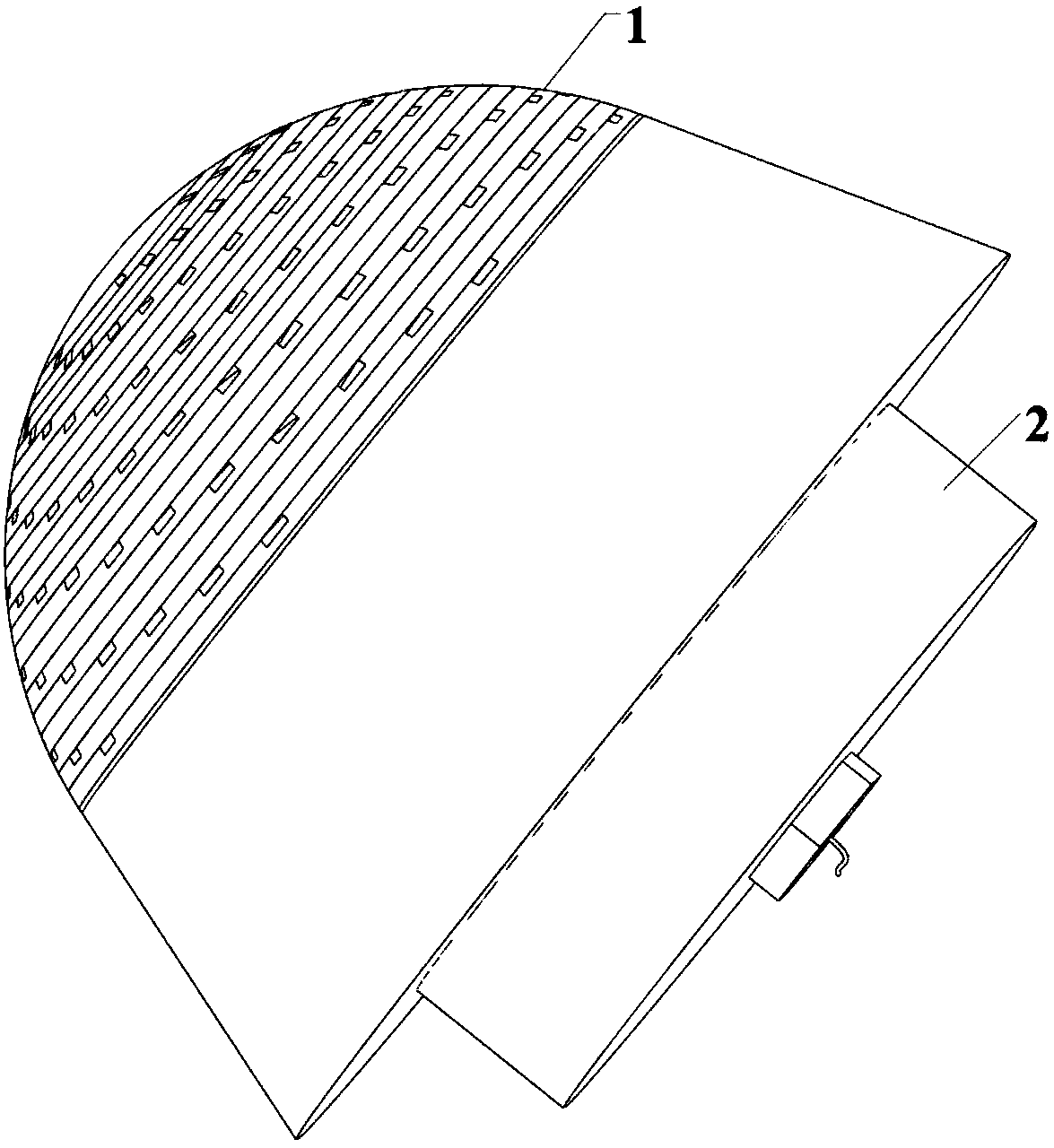

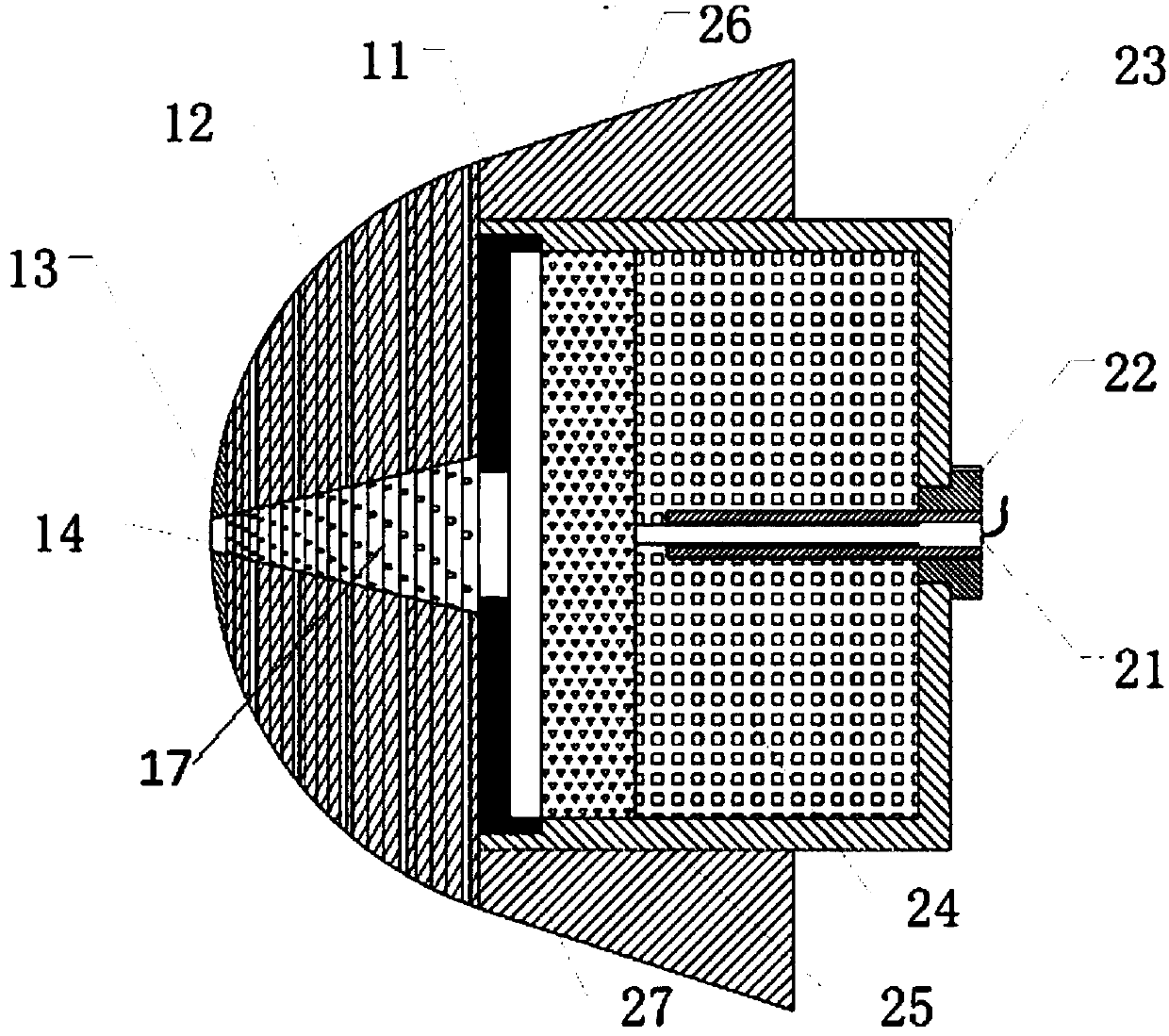

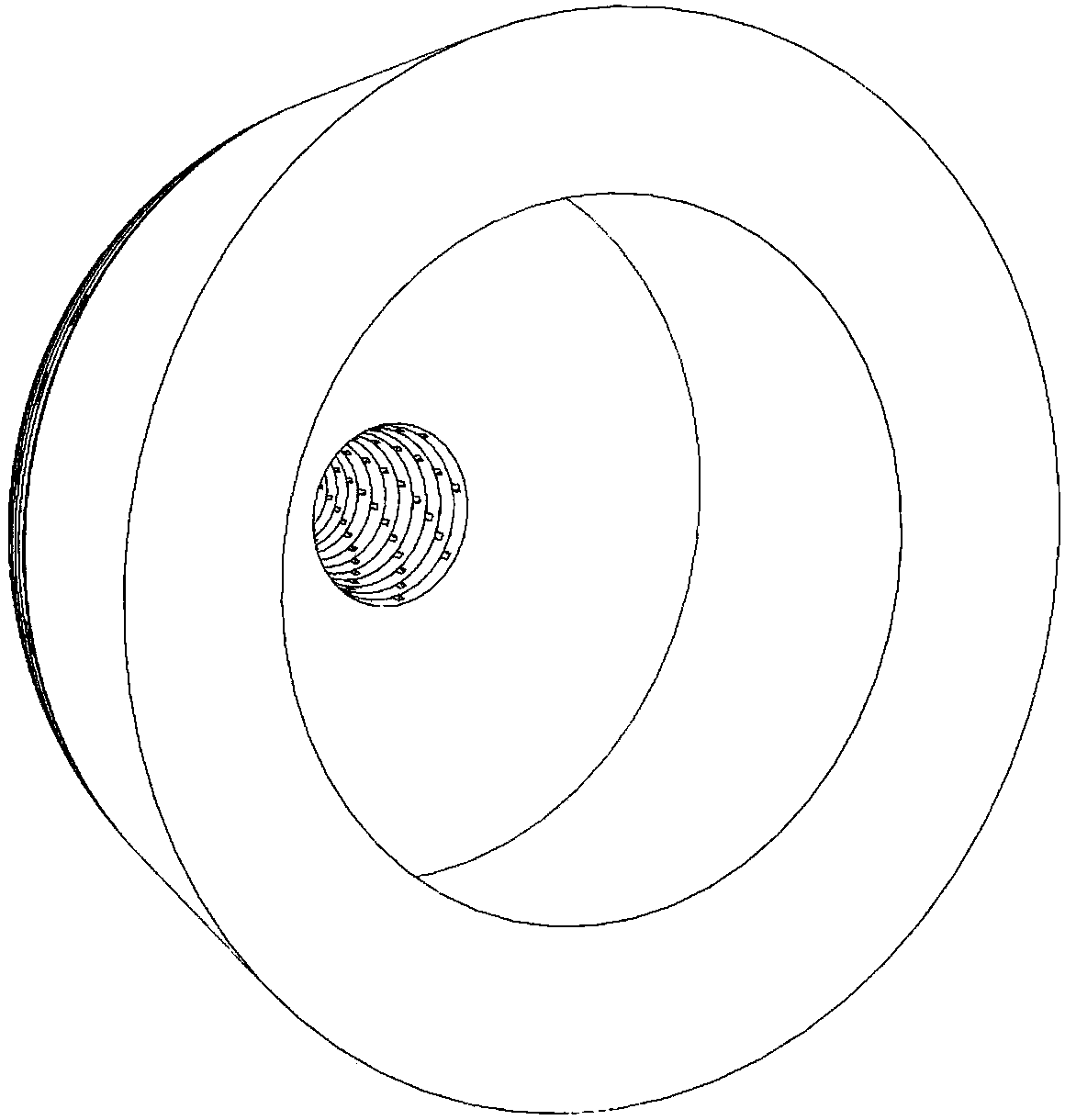

[0032] Figure 1 to Figure 5 It shows the related structure of a layered gas sweating nose cone of the present invention, specifically, the sweating nose cone includes a layered nose cone structure 1 and a gas generator 2, and the layered nose cone structure 1 includes a hollow circular Shaped bottom platform 11, the top surface of the circular bottom platform 11 is provided with a laminated body 12, the gas generator 2 is installed in the circular bottom platform 11, and the laminated body 12 is composed of multiple pieces with different heights. The ring-shaped sweating laminates 15 with increasing radii and successively decreasing radii are coaxially rotated and superimposed, and the central circular holes of the multiple sweating laminates 15 are stacked in sequence to form a coolant flow channel 17; the surface of the sweating laminates 15 is engraved There are 8 flow channels 16 radially distributed along the sweating laminate, and the 8 flow channels 16 are evenly distr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap