Lifting hook for crane

A technology of cranes and hooks, which is applied in the field of mechanical accessories, can solve problems such as impact, poor toughness, and poor wear resistance, and achieve the effects of stable engagement, improved wear resistance, overall strength and surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

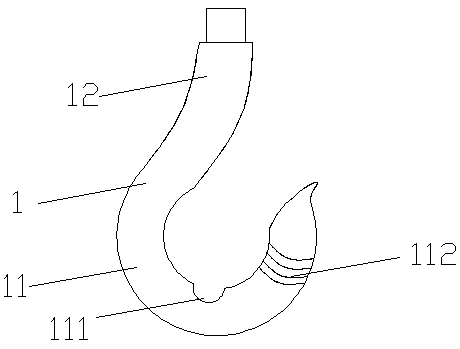

[0017] Such as figure 1 As shown, a hook for a crane includes a plate hook 1, and the plate hook 1 includes a hook body portion 11 and a hook neck portion 12. A groove 111 is fixedly arranged on the plate hook body portion 11, and the diameter of the groove 111 is at least 20mm. The depth is at least 20mm, the groove 111 is integrated with the hook body 11 of the plate hook, the groove 111 is made of alloy, and the surface is made by quenching and firing.

[0018] In the above embodiment, a groove 111 is provided on the hook body 11 of the plate hook to fix the wire rope and prevent the wire rope from shaking during transportation and falling off from the hook; the material of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap