Ceramic glaze

A ceramic glaze and sepiolite technology, applied in the field of ceramic products, can solve the problems affecting the final product, poor glaze gloss, and many pinholes, so as to improve mechanical strength and thermal stability, reduce thermal expansion coefficient, increase Effect of Glaze Gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

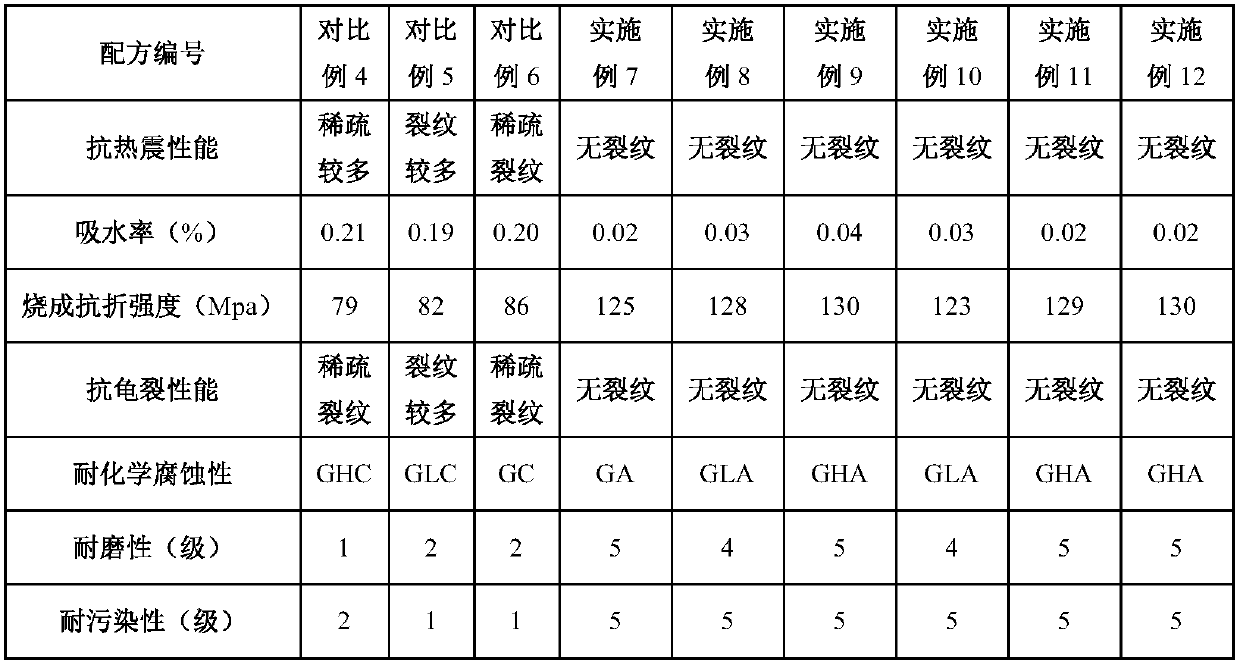

Examples

Embodiment 7

[0014] Embodiment 7 A kind of preparation of ceramic glaze

[0015] Preparation

[0016] Weigh the raw materials according to the raw material formula in Example 1; grind the glaze, crush it, and pass through a 100-200 mesh sieve; add 1-1.5 times the water of the glaze weight to the raw materials; use the brushing process to brush the glaze slurry on Ceramic blanks are sent to the kiln for firing. The firing steps are divided into four stages: the first stage: the heating stage from room temperature to T1, with an average heating rate of 15-20°C / min; the second stage: the heating stage from T1 to T2, with an average heating rate of 10-15°C / minute ; The third stage: T2 heat preservation stage, the heat preservation time is 30-60 minutes; the fourth stage: the cooling stage from T2 to room temperature, natural cooling. The range of T1 is 700-750°C, and the range of T2 is 1000-1200°C.

Embodiment 8

[0017] Embodiment 8 A kind of preparation of ceramic glaze

[0018] The raw material formula of Example 2 is used to prepare ceramic glaze, and the preparation method refers to Example 7.

Embodiment 9

[0019] Embodiment 9 A kind of preparation of ceramic glaze

[0020] The raw material formula of Example 3 was used to prepare ceramic glaze, and the preparation method was referred to Example 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap