Rapid refueling and purifying equipment for petroleum drilling and fracturing

A purification equipment and oil drilling technology, which is applied in the field of oil extraction, can solve problems such as engine combustion system not working properly, well site HSE hidden dangers, fuel filter damage, etc., to achieve easy installation, improve filtration efficiency, and prolong service time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

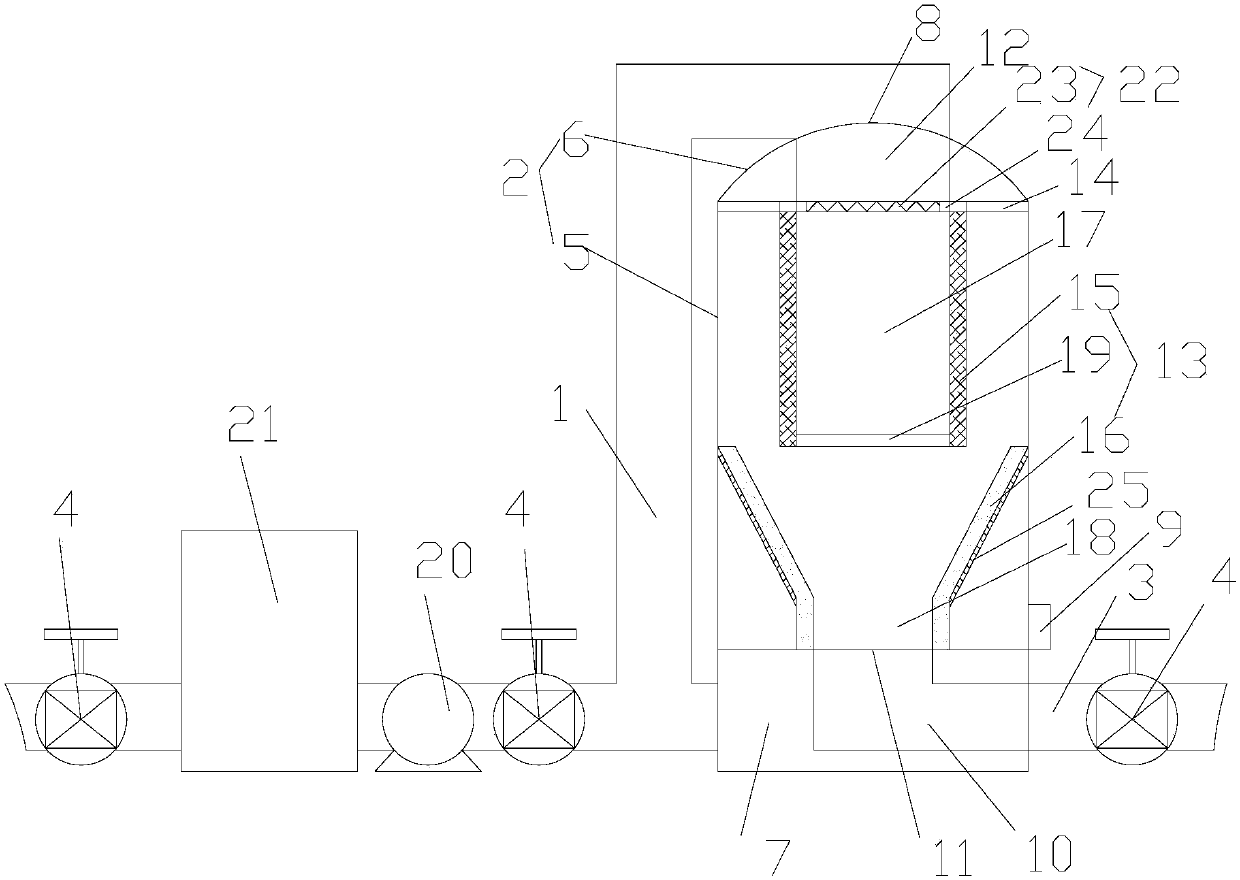

[0020] Please refer to figure 1 , the present invention provides oil drilling and fracturing fast refueling purification equipment, the purification equipment includes a purification oil inlet pipeline 1, a purification tank 2 and a purification oil outlet pipeline 3, and the purification oil inlet pipeline 1 is connected to the liquid inlet end of the purification tank 2 The purified oil outlet pipeline 3 communicates with the liquid outlet of the purification tank 2, and the purified oil inlet pipeline 1 and the purified oil outlet pipeline 3 are provided with valves 4.

[0021] Working principle: The oil from the refueling truck is transported to the purification tank 2 through the purification oil inlet pipeline 1 for purification, and then the clean oil is output through the purification oil outlet pipeline 3 and delivered to the fuel tank of the fracturing vehicle. The valve setting is used to control Whether the oil is delivered or not, and if the oil delivery pressure ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap