Device and method for high-locality micro electrodeposition of piezoelectric ceramics by adopting laser shocking

A technology of piezoelectric ceramics and laser shock, applied in the direction of circuits, semiconductor devices, etc., can solve the problems of complex operation process and numerous processes, and achieve the effects of strong controllability, simple operation, and poor localization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

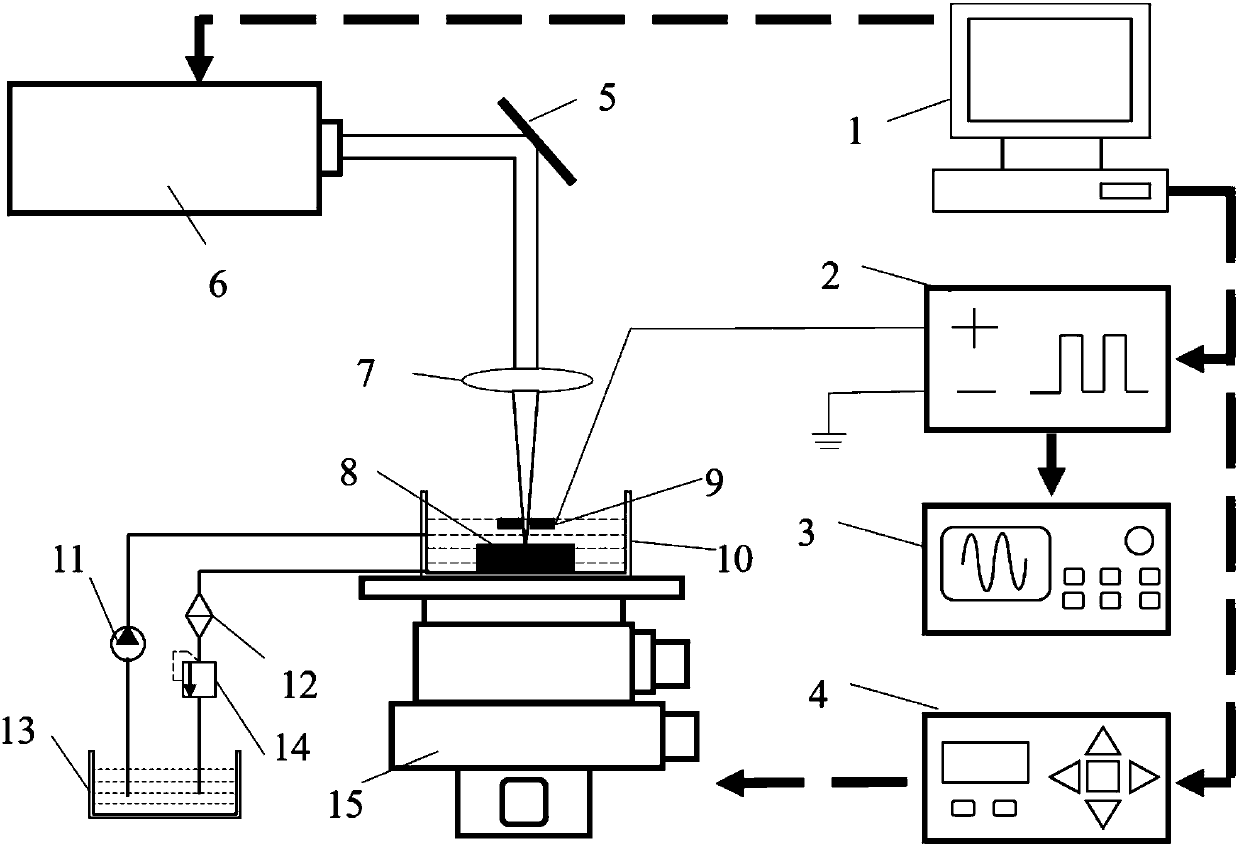

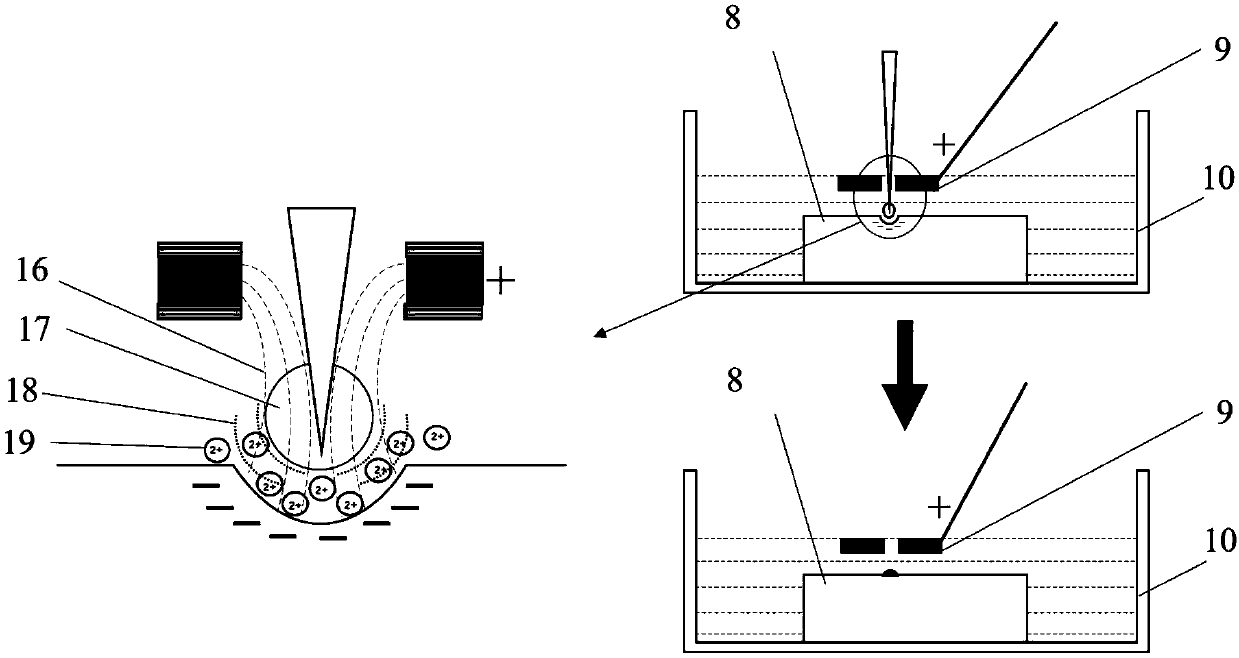

[0035] Attached figure 1 The computer 1 is connected to the laser 6, the DC pulse power supply 2, and the motion control card 4. The computer 1 can control the laser parameters of the pulse laser 6 and the DC pulse power supply 2 power parameters, and can also transmit the compiled code to the motion control card 4. The oscilloscope 3 is connected to the DC pulse power supply 2 to monitor current parameters in real time; the working tank 10 is placed on the xyz three-axis worktable 15, the piezoelectric ceramic substrate 8 and the anode tool 9 are both placed in the working tank 10; the laser beam is emitted from the laser 6 , The transmission direction is changed by the reflection of the mirror 5, and then the through hole of the anode tool 9 is focused through the focusing lens 7 to focus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com