Prestressed carbon fiber tensioning device

A technology of tensioning device and carbon fiber, which is applied in bridge maintenance, erection/assembly of bridges, bridge materials, etc., can solve the problem of low efficiency of structural reinforcement, low epoxy structural elastic modulus, unfavorable structural force transmission, and influence on reinforcement Issues such as technology promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, the present invention will be further described in detail through the drawings and specific embodiments.

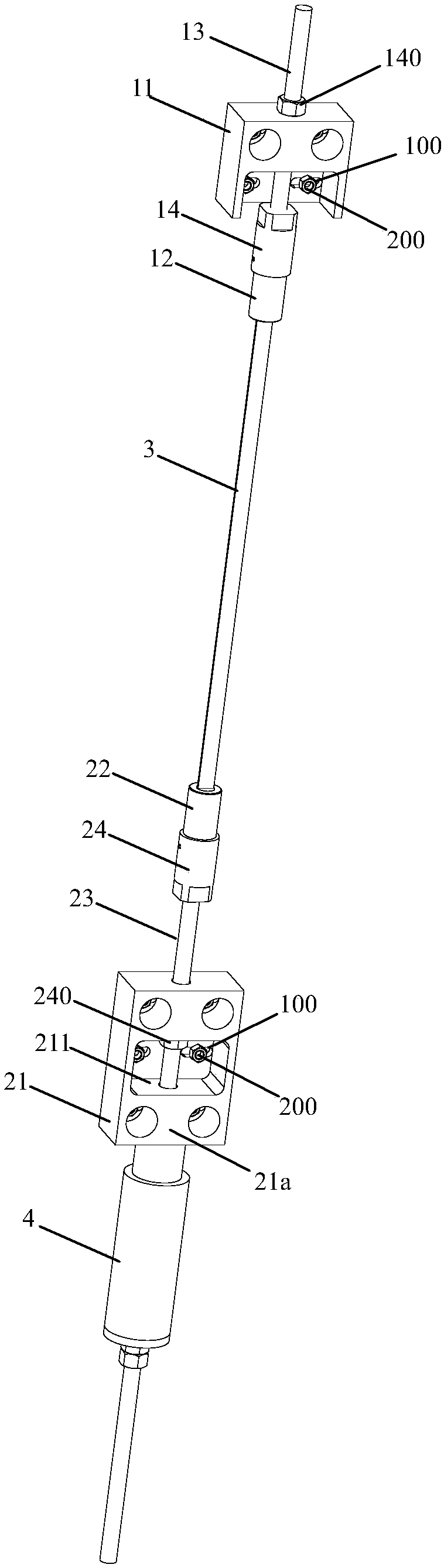

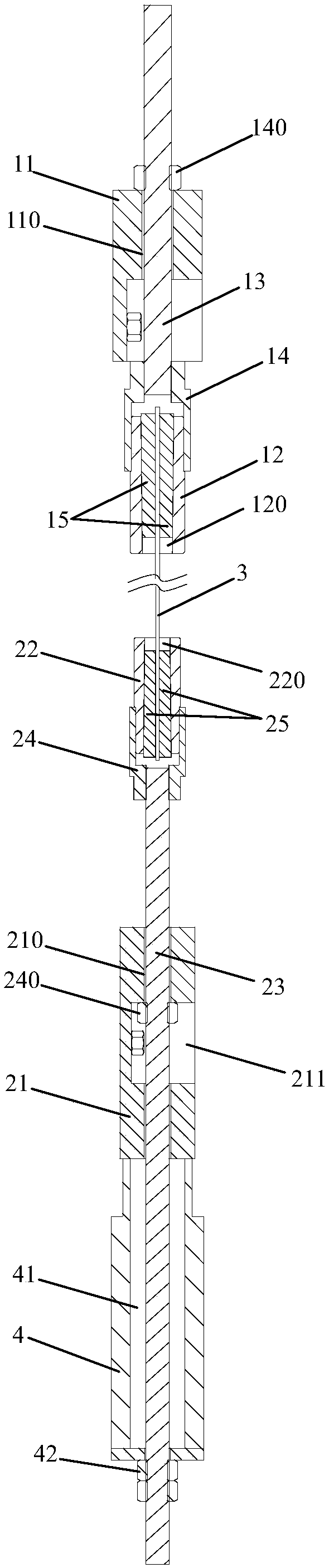

[0017] As shown in the figure, this embodiment provides a prestressed carbon fiber tension device, which includes a fixed end base 11, a fixed end anchor block 12, a carbon fiber tension cable 3, a tension end anchor block 22, and a tension end base 21. The fixed end anchor block 12 and the tension end anchor block 12 are cylindrical and are respectively fixed to the two ends of the tension cable 3; the fixed end anchor block 12 is connected to one end of a fixed screw 13, the The other end of the fixed screw 13 passes through the fixed end piercing hole 110 of the fixed end base 11 and then is screwed to a fixed nut 140; the tension end anchor block 22 is connected to one end of a pull screw 23, the The other end of the tension screw 23 passes through the tension end piercing hole 210 on the tension end base 21 and is connected to the jack 4; a cavity 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com