Energy-saving sweeper based on technology of baffle-skirt-type conveyor belts for garbage conveying

A transmission technology and conveyor belt technology, applied in the field of environmentally friendly vehicles, can solve the problems of equipment cost and operation ineffective power increase, garbage residue, difficult adsorption and transmission, etc., to avoid the interference of relative position changes, facilitate installation and replacement, and reduce dust. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

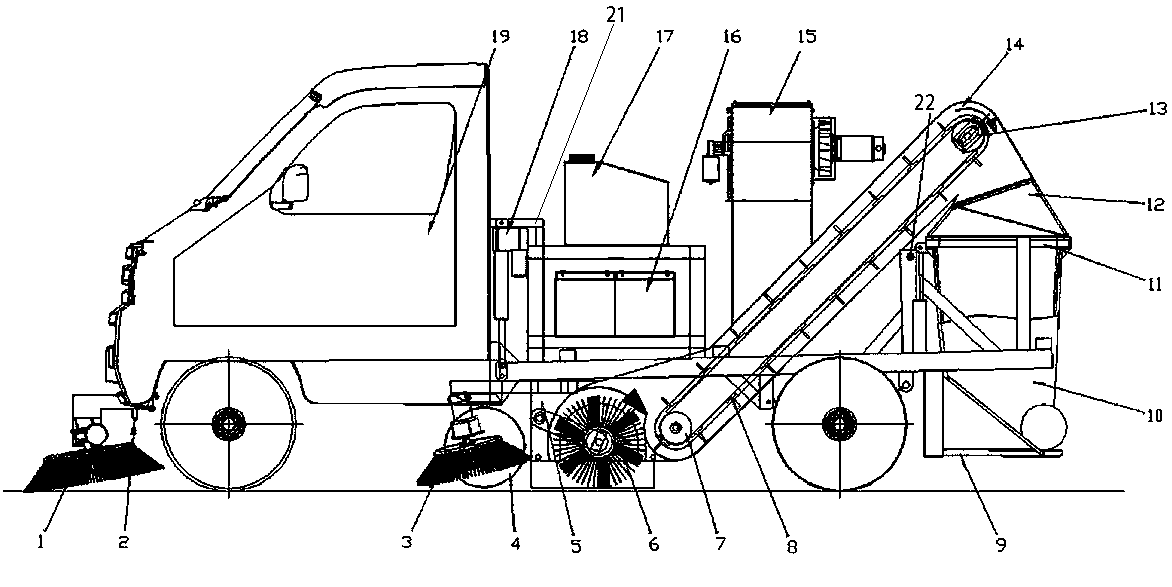

[0009] figure 1 Middle: front side brush 1, water nozzle 2, middle side brush 3, universal wheel 4, main brush bucket 5, main brush 6, driven roller 7, conveyor belt 8, trash can lifting mechanism 9, said trash can 10, Upper frame 11, soft connection mechanism 12, electric drum 13, delivery bucket 14, dust suction mechanism 15, battery 16, water tank 17, push rod 18, vehicle chassis 19, main frame 21, delivery bucket rotating hinge 22.

[0010] The energy-saving cleaning vehicle based on the baffle skirt type conveyor belt garbage transmission technology includes a vehicle chassis 19 and a garbage cleaning assembly. The garbage cleaning assembly includes a main brush 6, a universal wheel 4, a middle side brush 3, a main brush bucket 5, Garbage conveying mechanism, the main brush 6 is driven by the main brush motor, and the main brush is a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com