Metal roof balance layer structure

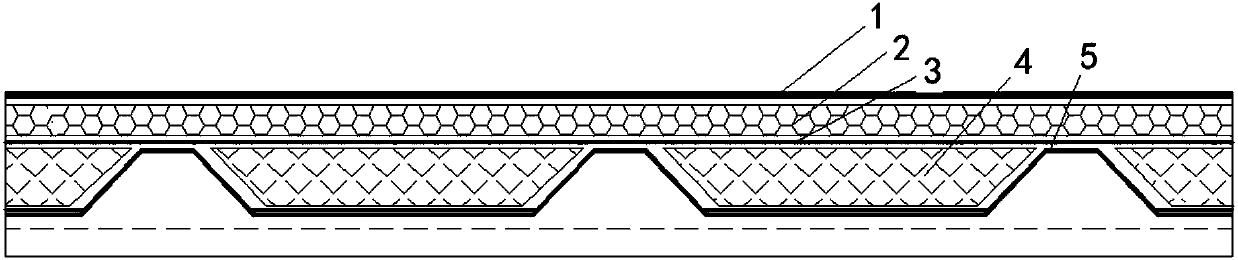

A metal roof and balance layer technology, applied in the direction of roof covering layer, roof, roof using flat/curved panels, etc., can solve the problems of increased roof load, a large amount of lightweight debris, and a large amount of manual engineering, reducing the need for The effect of on-site operation procedures and manual engineering, good windy weather, and increased roof load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

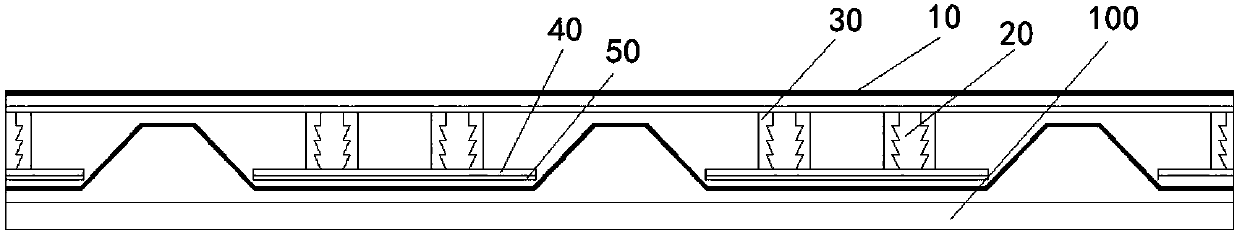

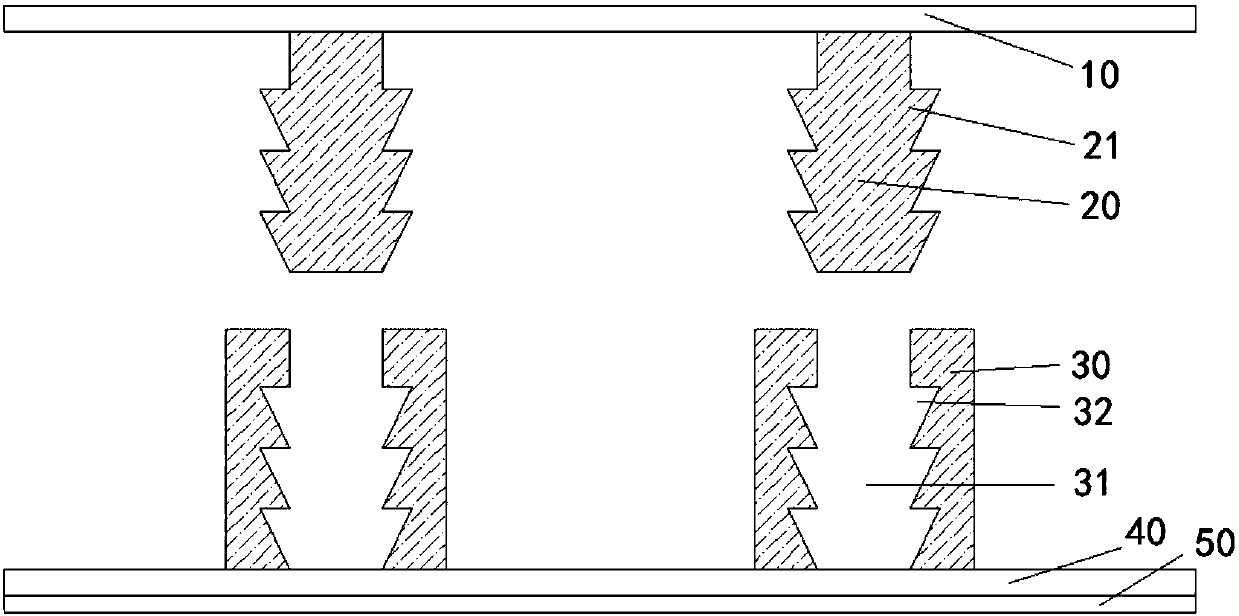

[0040] Such as Figure 2-3 As shown, the present invention provides a metal roof balance layer structure, comprising:

[0041] At least one top plate passes through 10, and the lower surface of the top plate through 10 is fixedly connected with a plurality of support columns passing through 20;

[0042] A plurality of bottom plate passes through 40, and the upper surface of the bottom plate through 40 passes through is fixedly connected with a plurality of limit concave post passes through 30 that are matched with the support column through 20 through one by one, so The limiting concave column passes through 30 and the support column passes through 20 through the snap connection, the size of the bottom plate passing through 40 is suitable for the size of the metal roof trough, and the bottom plate passing through 40 The lower surface of the metal roof is connected with the trough of the metal roof;

[0043] Each of the top plates passes through 10 passes through the upper su...

Embodiment 2

[0057] Such as Figure 2-3 As shown, the present invention provides a metal roof balance layer structure, comprising:

[0058] At least one top plate passes through 10, and the lower surface of the top plate through 10 is fixedly connected with a plurality of support columns passing through 20;

[0059] A plurality of bottom plate passes through 40, and the upper surface of the bottom plate through 40 passes through is fixedly connected with a plurality of limit concave post passes through 30 that are matched with the support column through 20 through one by one, so The limiting concave column passes through 30 and the support column passes through 20 through the snap connection, the size of the bottom plate passing through 40 is suitable for the size of the metal roof trough, and the bottom plate passing through 40 The lower surface of the metal roof is connected with the trough of the metal roof;

[0060] Each of the top plates passes through 10 passes through the upper su...

Embodiment 3

[0075] Such as Figure 2-3 As shown, the present invention provides a metal roof balance layer structure, comprising:

[0076] At least one top plate passes through 10, and the lower surface of the top plate through 10 is fixedly connected with a plurality of support columns passing through 20;

[0077] A plurality of bottom plate passes through 40, and the upper surface of the bottom plate through 40 passes through is fixedly connected with a plurality of limit concave post passes through 30 that are matched with the support column through 20 through one by one, so The limiting concave column passes through 30 and the support column passes through 20 through the snap connection, the size of the bottom plate passing through 40 is suitable for the size of the metal roof trough, and the bottom plate passing through 40 The lower surface of the metal roof is connected with the trough of the metal roof;

[0078] Each of the top plates passes through 10 passes through the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com