Coal mining machine video analyzing and controlling system

A video analysis and control system technology, applied in the field of video analysis systems, can solve problems such as poor working environment, low working efficiency of coal shearers, and reduced machine life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

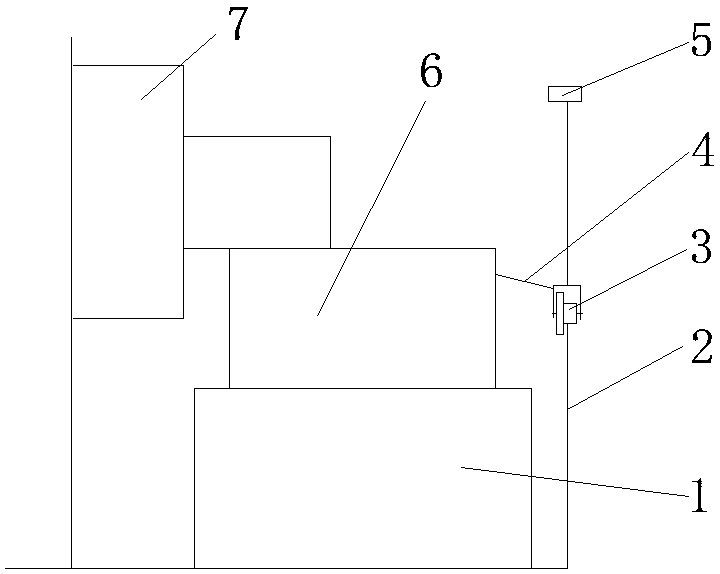

[0016] Such as figure 1 , 2 , 3, the shearer 6 is installed on the scraper conveyor 1, and a coal blocking plate 2 is installed on the right side of the scraper conveyor. The coal rock identification device 5 is mounted on the track trolley 3, and the track trolley utilizes the upper end face of the coal retaining plate as a moving track to pass through the connecting rod 4 and the shearer.

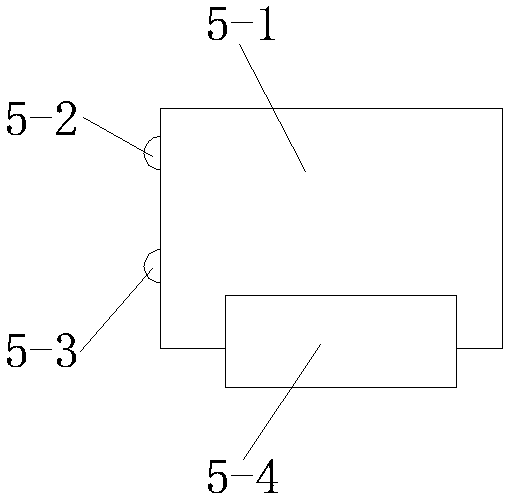

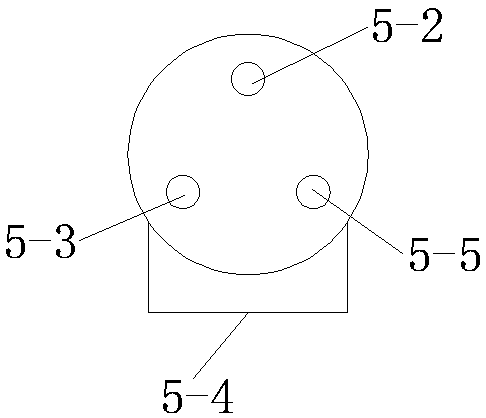

[0017] The coal rock identification device 5 comprises a frame 5-1, a camera 5-2 installed in the frame, an infrared light source 5-3, and an ultraviolet light source 5-4, and the image information collected by the camera is transmitted to the computer through an optical cable or a wireless transmission device , the computer determines the boundary between the coal seam and the rock through image analysis software, and is connected with the control part of the coal mining machine for controlling the uppermost and lowermost edges of the coal mining drum 7 in the coal mining machine 6 to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com