Small-sized, high frequency and high linearity jet deflection plate type electro-hydraulic servo valve and using method thereof

An electro-hydraulic servo valve, high linearity technology, applied in servo meter circuits, servo motor components, fluid pressure actuators, etc., can solve the problems of servo valves being easily blocked, unbalanced force, slow dynamic response, etc. Achieve the effects of improving anti-pollution ability, avoiding stagnation and blockage, and reducing motion inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

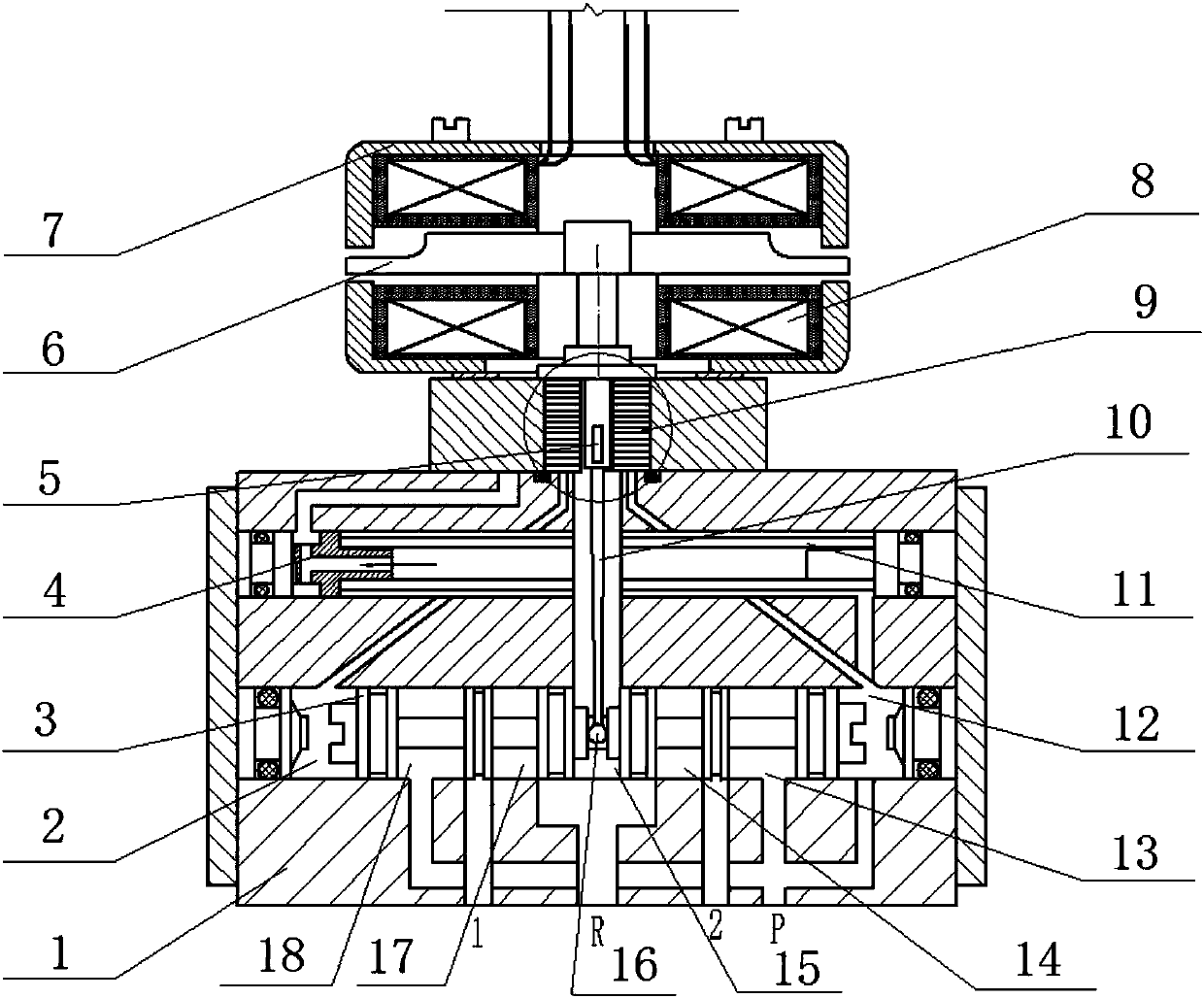

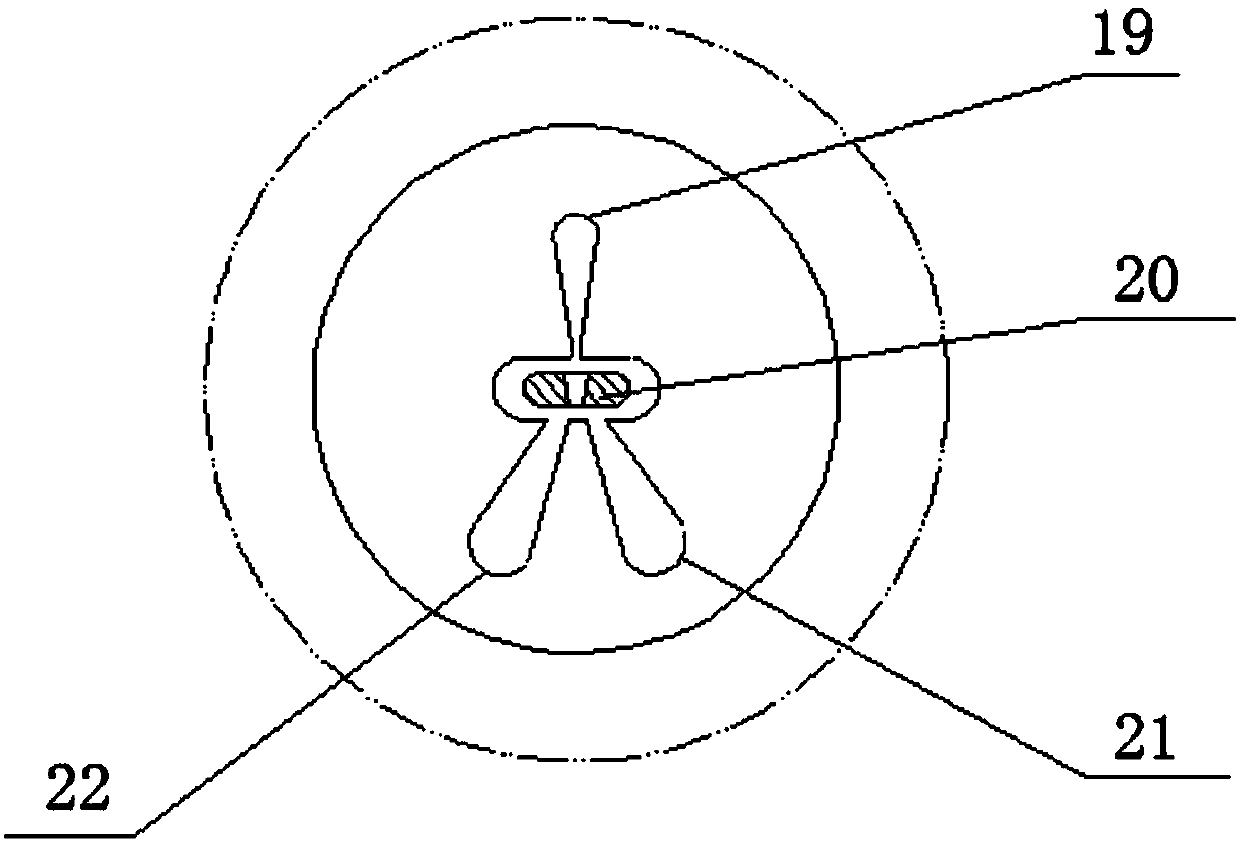

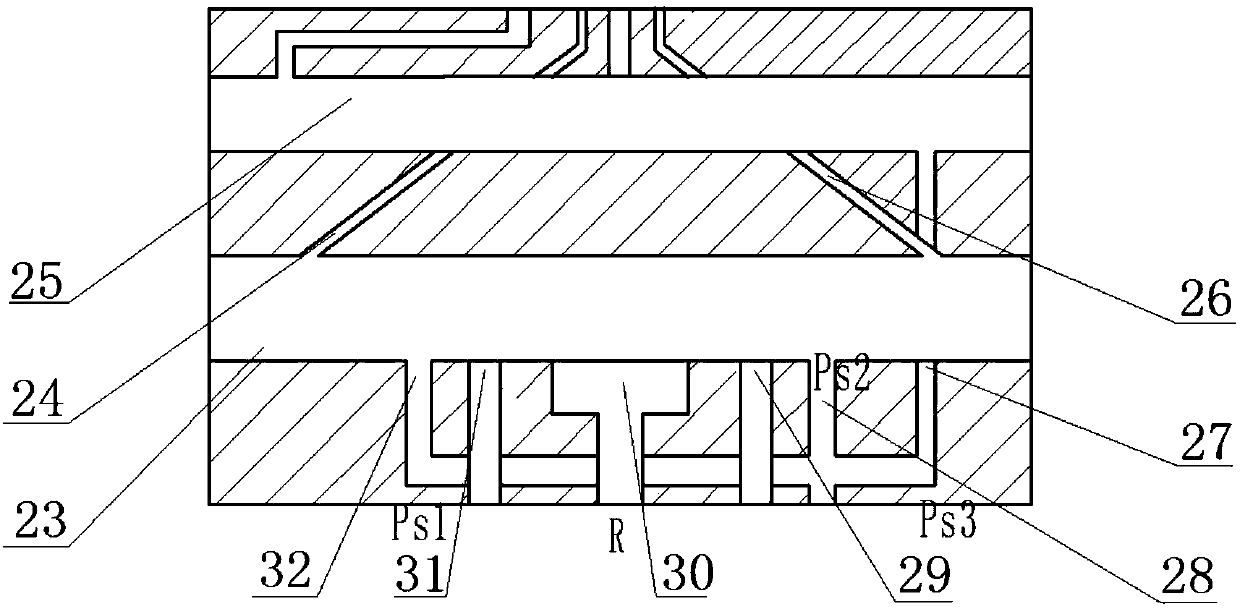

[0048] Referring to the accompanying drawings, it can be seen that a small-volume, high-frequency, high-linearity jet deflection plate electro-hydraulic servo valve includes a housing 1, a valve core 3, and an armature assembly 6; its feature is that the upper surface of the housing 1 is provided with a housing jet hole 33. The left receiving hole 35 of the housing, the right receiving hole 36 of the housing and the central hole 34 of the housing. The first-stage seat assembly 9 is installed above the central hole 34 of the shell. The first-stage seat assembly 9 includes a first-stage seat 49 and an upper pressure block 46 , the jet sheet 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com