Rotary air preheater and method for reducing air leakage and preventing blocking of primary air side

An air preheater, rotary technology, applied in regenerative heat exchangers, combustion methods, indirect heat exchangers, etc., can solve the problem of insufficient draft fan allowance, reduce equipment service life, and reduce air preheater replacement. Thermal capacity and other issues, to eliminate the air leakage problem on the primary air side and reduce the air leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

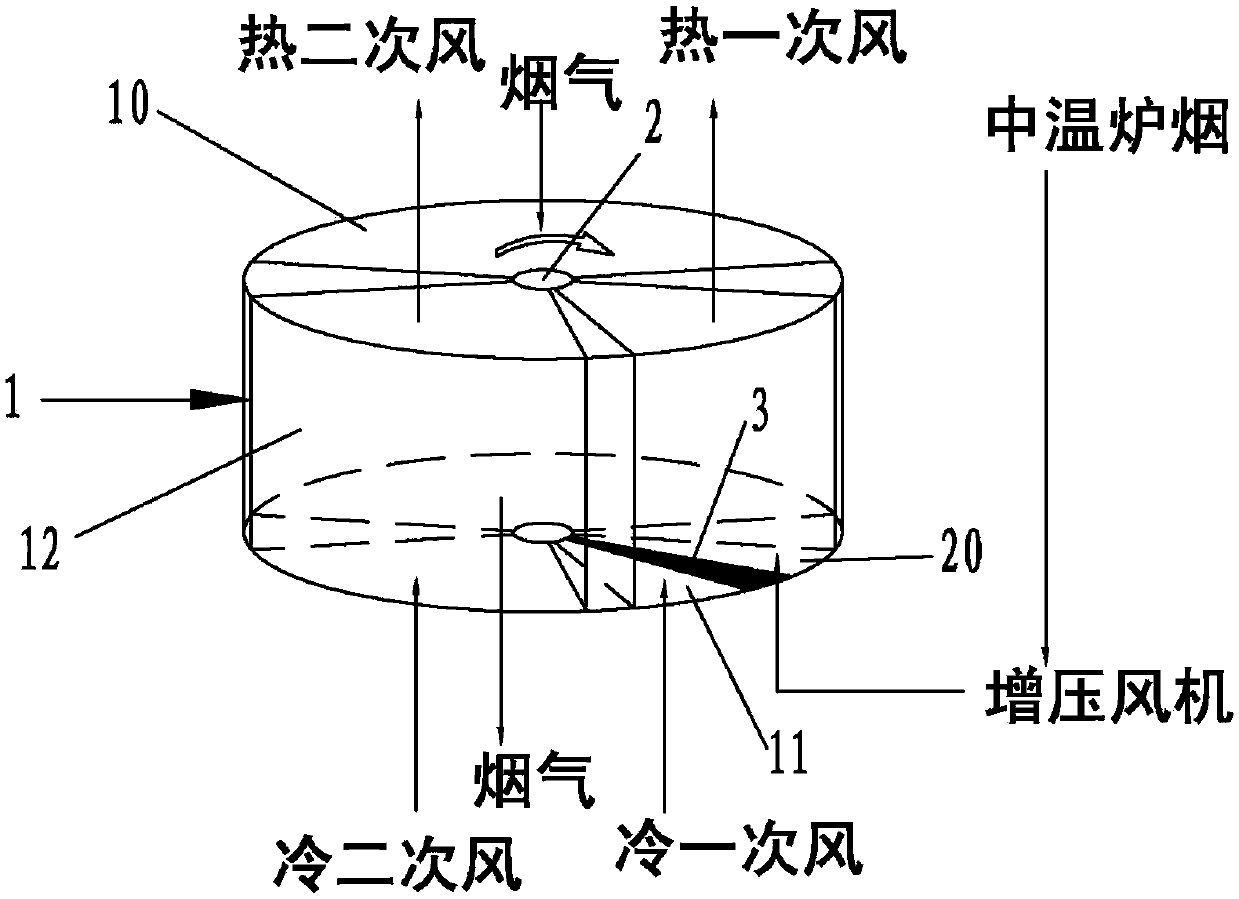

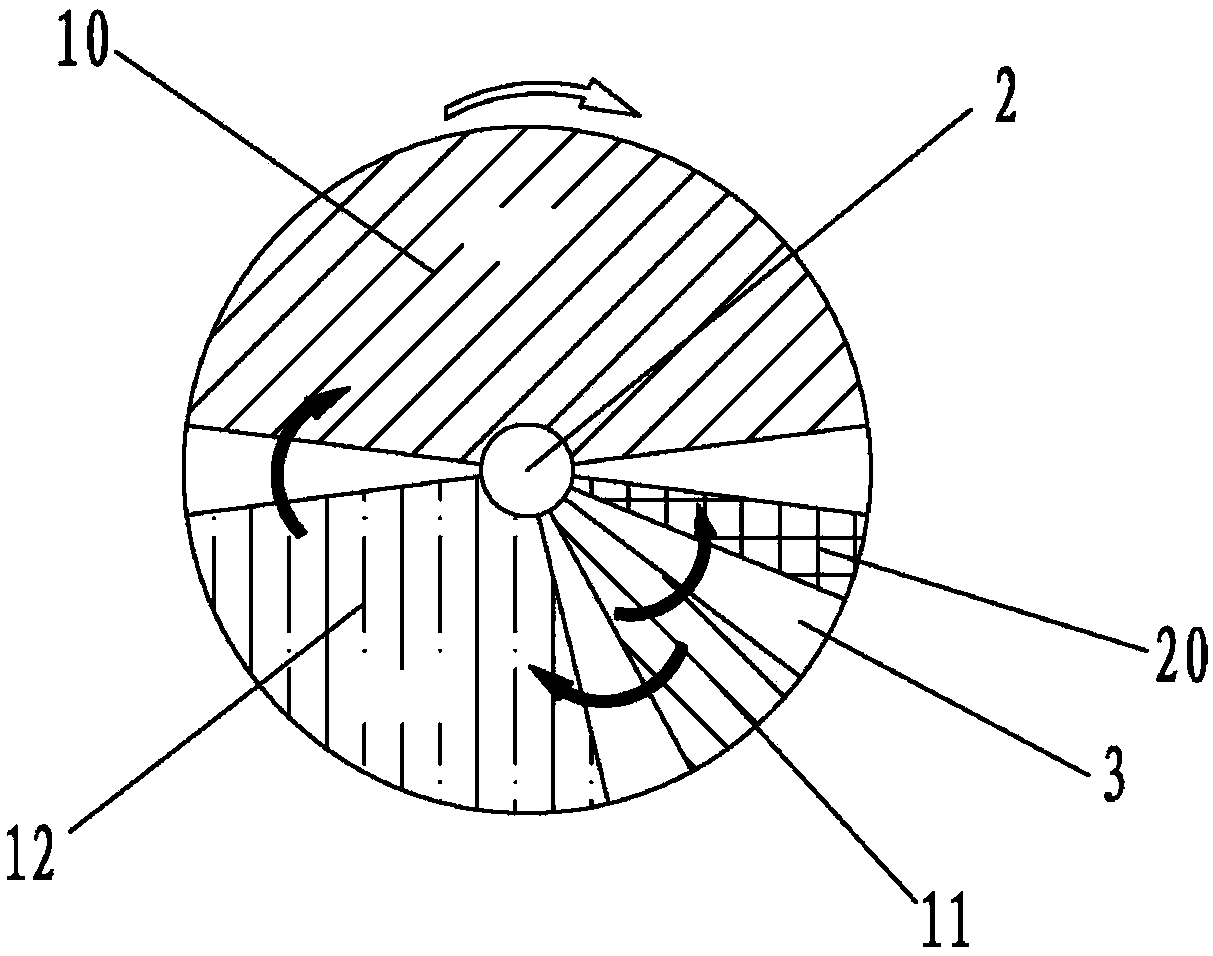

[0029] Such as figure 1 , figure 2 As shown, the rotary air preheater of the present invention includes a chamber 1 and a rotor 2 rotatably arranged in the center of the interior of the chamber. The rotor 2 is provided with heat exchange elements, and the chamber 1 is separated by a plurality of partitions. These are fan-shaped flue gas bins 10, primary air bins 11, and secondary air bins 12. The flue gas bins 10, primary air bins 11, and secondary air bins 12 are arranged circumferentially around the rotor in sequence and are all adjacent to the rotor 2. The primary air chamber is adjacent to the secondary air chamber, and the radially extending fan-shaped partition 3 is arranged in the primary air inlet at the bottom of the primary air chamber. The fan-shaped partition 3 separates the primary air chamber 11 into a fan-shaped heating compartment 20 for heating The short-arc side of the compartment 20 is adjacent to the rotor 2, the air inlet of other parts of the primary ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com