stove

A technology for stoves and combustion chambers, applied to household stoves/stoves, combustion air/flue gas circulation of stoves, stoves/stoves with convection heating devices, etc., which can solve the problem of increasing the load of the stove, increasing the manufacturing time and cost of the stove And purchase costs, difficult to transport and other issues, to achieve the effect of improving the heat insulation function, improving the effect of heat insulation and heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Hereinafter, the present invention will be described in detail with reference to the drawings.

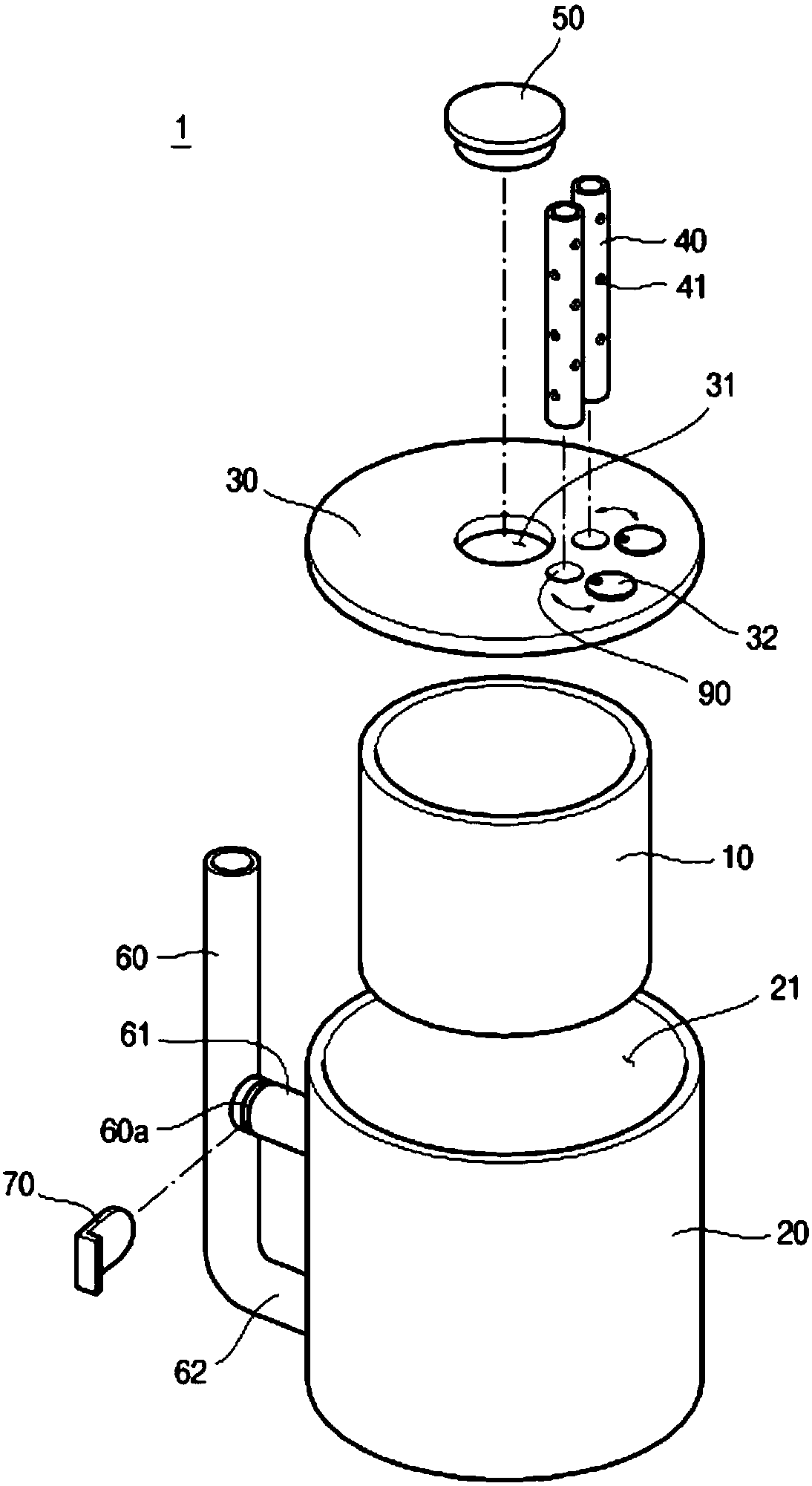

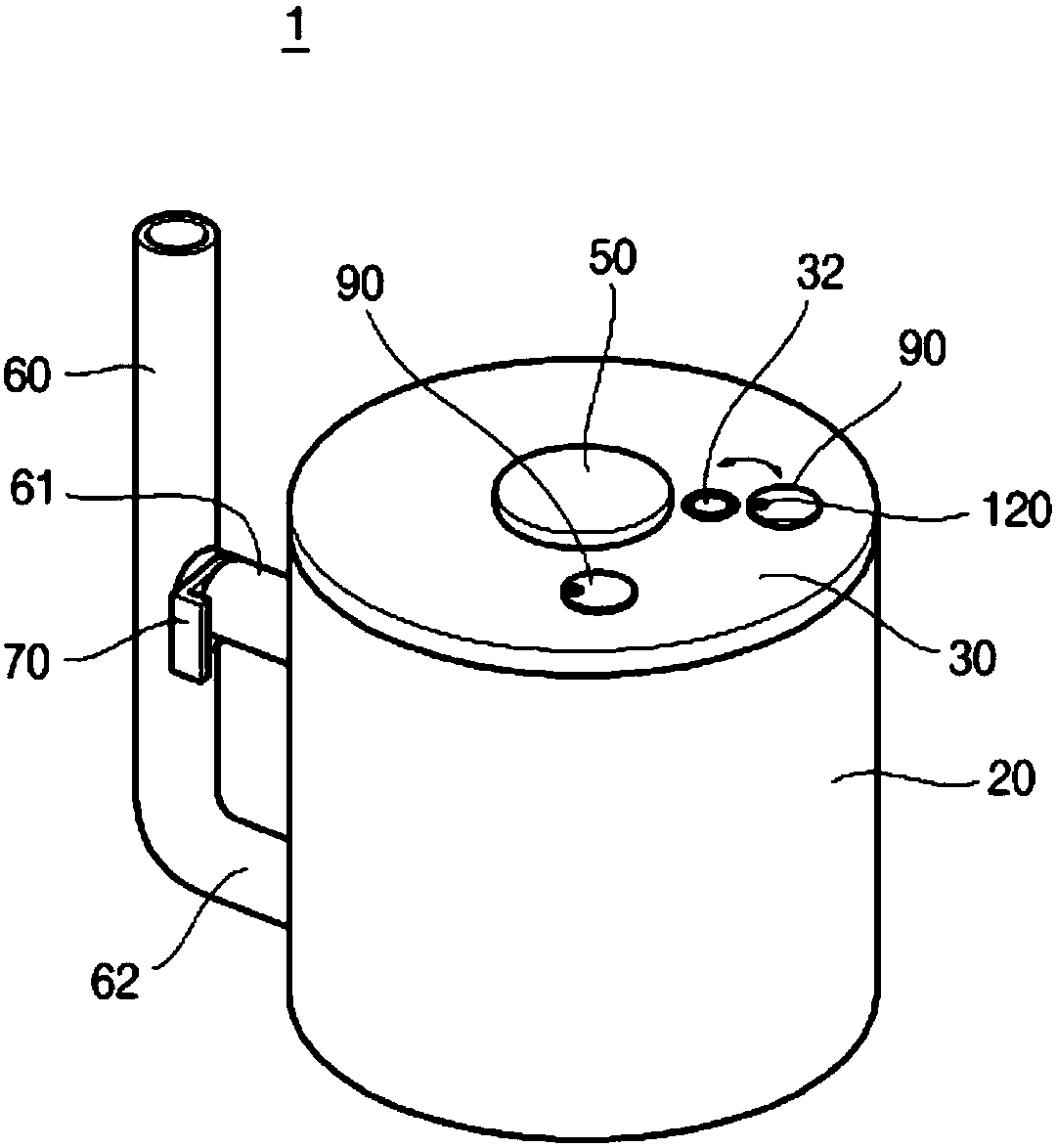

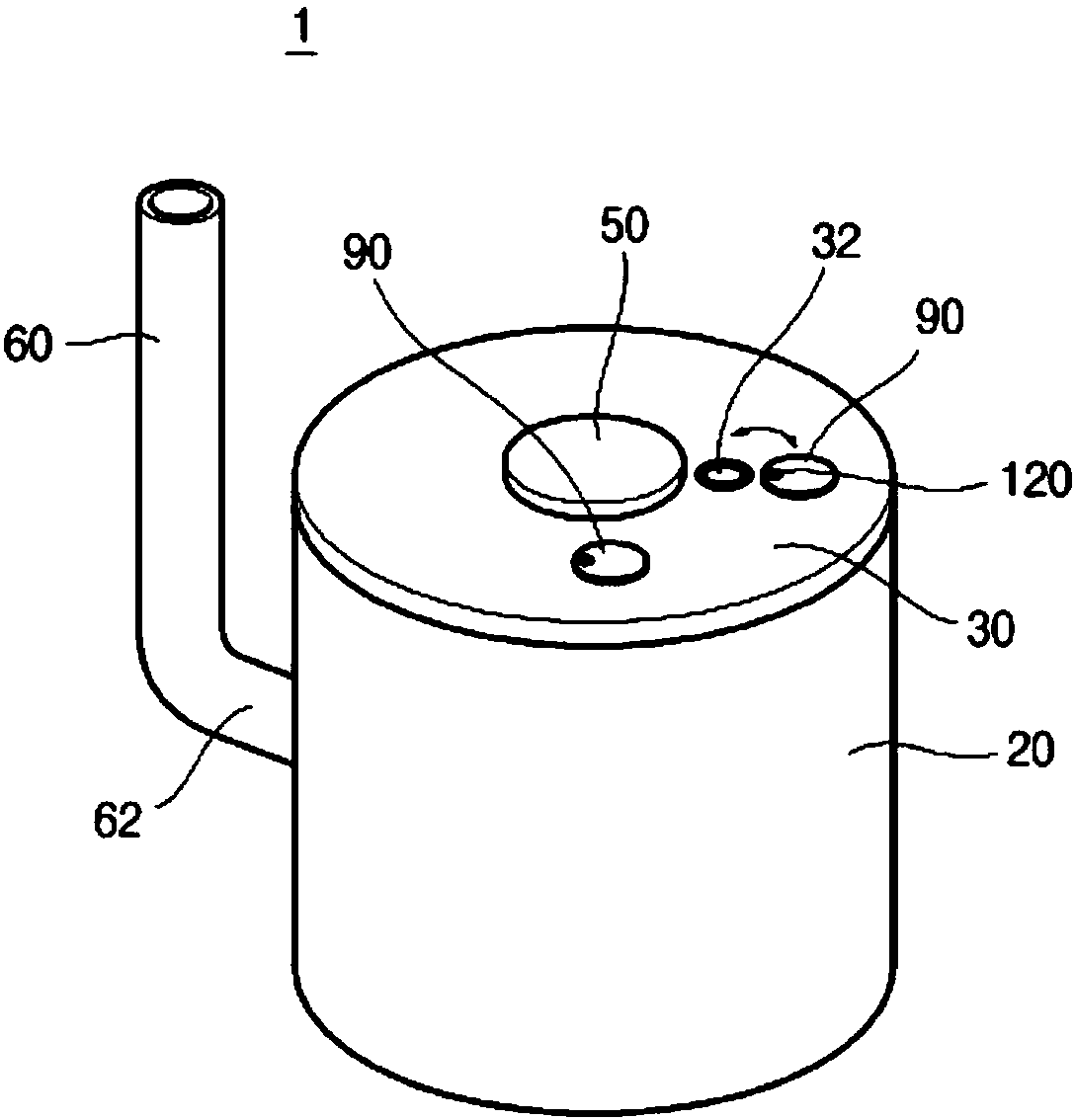

[0063] figure 1 To show an exploded perspective view of the stove of the present invention, figure 2 To show the combined perspective view of the stove of the present invention, image 3 In order to show a combined perspective view of an embodiment of the chimney applied to the stove of the present invention, Figure 4 To show a plan view of a state where the main body of the furnace applied to the present invention is inserted into the heating unit in an eccentric state, Figure 5 To show a cross-sectional view of the state in which the auxiliary combustion tube is applied to the furnace of the present invention, Image 6 To show a cross-sectional view of the state in which the auxiliary combustion tube and the auxiliary gas supply unit are applied to the furnace of the present invention, Figure 7 In order to show a cross-sectional view of the auxiliary input unit applied to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com