Air efficiency optimization system for clean space

A clean space and gas technology, applied in the field of central air conditioning, can solve the problems of positive pressure in clean space, economic losses of enterprises, large exhaust air volume, etc., and achieve the effect of avoiding waste, energy saving, environmental protection and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

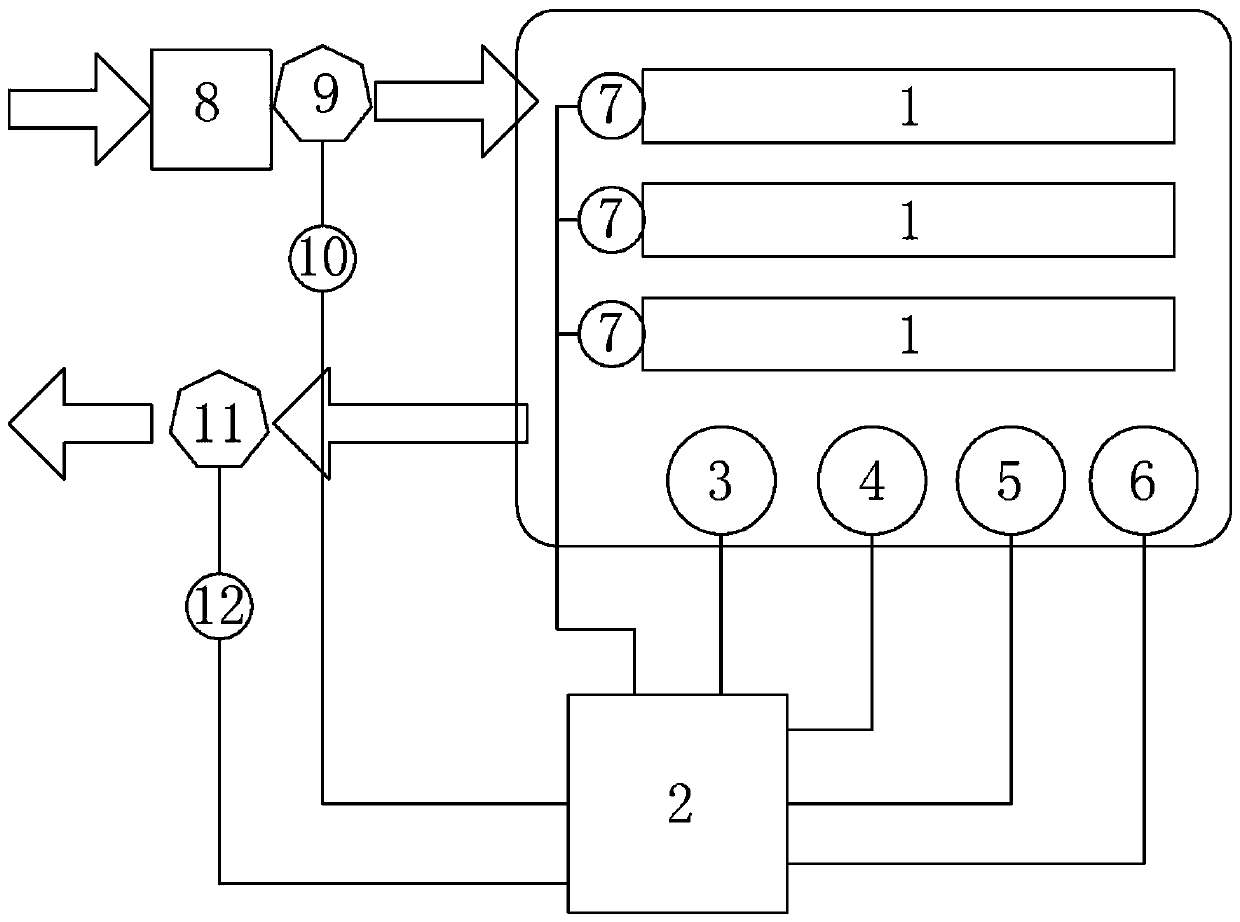

[0011] refer to figure 1 , a clean space gas efficient system, the clean space is provided with a fresh air system, an exhaust system and a production line 1, the efficient system includes a controller 2 (computer host or industrial control single-chip microcomputer), the input end of the controller 2 is connected to There are air pressure detection module 3 (precision atmospheric pressure gauge, output analog signal), temperature and humidity detection module 4 (electronic thermometer and electronic hygrometer, output analog signal number), oxygen content detection module 5 (oxygen sensor), solid particle The detection module 6 (PM2.5 sensor) and the linkage detection device 7 connected to the production line (connected in parallel at both ends of the switch of the power supply of the production line, and the switch closing or opening signal is obtained through a semiconductor device or a sampling resistor); the controller 2 The output end is connected with the fresh air syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com