A kind of antifreeze control method of indirect air cooling system

A technology of an air cooling system and a control method, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the problems of increased back pressure of steam turbines, increased coal consumption of generator sets, large water temperature differences, etc., and achieves power generation efficiency. High, improve the uniformity of water temperature, and the effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

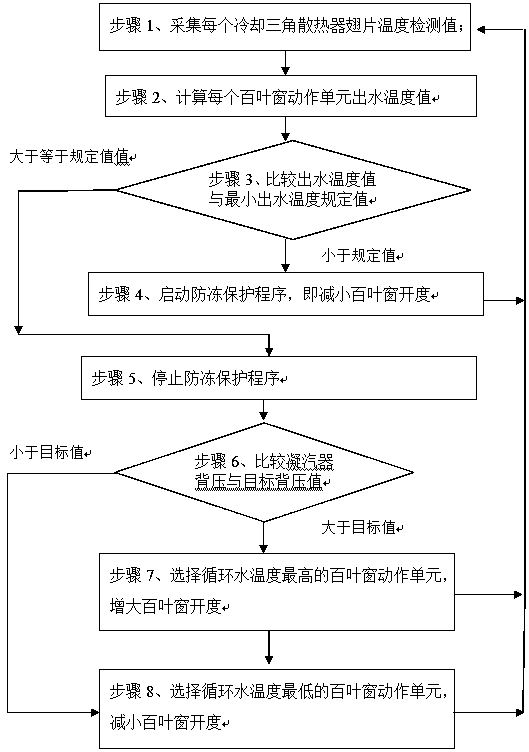

Method used

Image

Examples

Embodiment 1

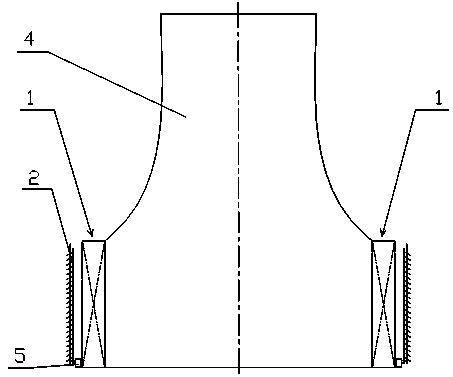

[0026] figure 1 It is a schematic diagram of the composition of the prior art indirect air cooling system. The indirect air cooling system is composed of air cooling radiator 1, louvers 2, cooling tower body 4 and driver 5. The air-cooling radiator 1 is vertically arranged on the bottom circumference of the cooling tower 4, and the air-cooling radiator 1 composed of many cooling triangles is divided into a plurality of cooling sectors, and each cooling sector includes a plurality of cooling triangles; in the cooling triangle (air-cooling radiator ) The louvers 2 are arranged at the air inlet, and the louvers 2 are driven by the driver 5 to realize the opening and closing functions. The function of the louver 2 is to adjust the air flow passing through the air-cooled radiator 1, so as to achieve the purpose of antifreezing and maintaining the target back pressure of the steam turbine in winter.

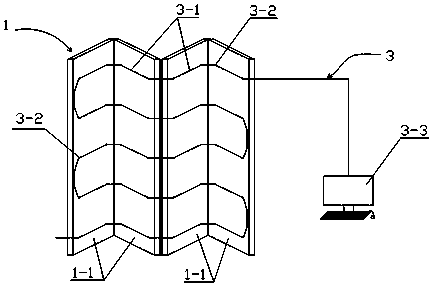

[0027] figure 2 It is the composition of the optical fiber grating detection d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com