Bamboo and wood artware raw material cooking insect prevention equipment

A handicraft and raw material technology, applied in wood treatment, mechanical equipment, wood treatment details, etc., can solve the problems of large labor input and low efficiency of bamboo and wood cooking, so as to speed up liquid flow, improve cooking quality and cooking efficiency, and improve cooking efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

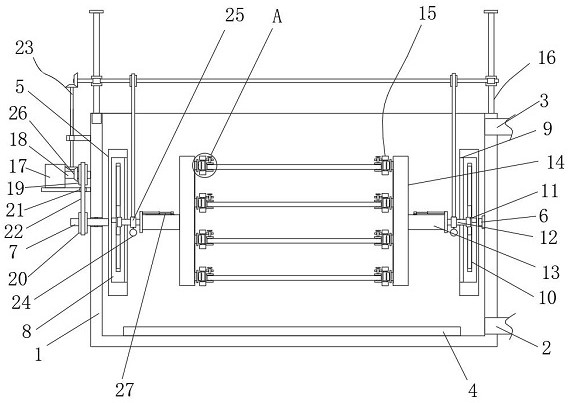

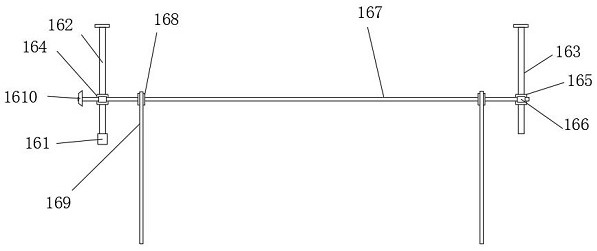

[0031] Example one, by Figure 1 to Figure 7Given, the present invention includes a cooking box 1, a water outlet pipe 2 and a water inlet pipe 3, the water outlet pipe 2 is located at the bottom end of one side of the cooking box 1, the water inlet pipe 3 is located at the top of one side of the cooking box 1, and the water inlet pipe 3 is located at the water outlet pipe Below 2, the inner bottom end of the cooking box 1 is provided with a heating device 4. Through the design of the heating device 4, it is convenient to realize the heating of the cooking liquid. The interior of the cooking box 1 is symmetrically provided with two rotating plates 5, one of which is a rotating plate. One side of 5 is connected with the inner wall of the cooking box 1 through the installation shaft 6, and one side of the other rotating plate 5 is connected with a rotating shaft 1 7, and the rotating shaft 1 7 penetrates the side wall of the cooking box 1 and extends to the cooking box 1. outsid...

Embodiment 2

[0034] Embodiment 2, on the basis of Embodiment 1, by figure 1 Given, the bottom end of the motor one 17 is provided with a support plate, and the support plate is provided with an opening 21 sleeved on the outside of the conveyor belt 22 to facilitate the rotation of the rotating plate 5, thereby providing convenience for the rotation of bamboo and wood.

Embodiment 3

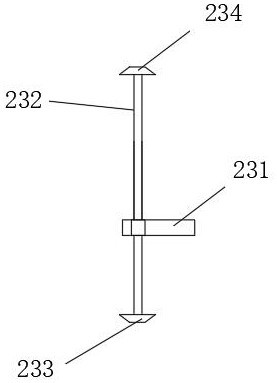

[0035] Embodiment 3, on the basis of Embodiment 1, by figure 1 and Image 6 Given, the connecting shaft 12 is sleeved with a collar 25, it should be noted here that the collar 25 and the connecting shaft 12 are connected by a bearing, the bearing is not shown in the figure, and the bottom ends of the collar 25 are connected There are gravity balls 24 , so that the collar 25 can be prevented from rotating synchronously with the connecting shaft 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com