Method for automatically searching normal line direction of on-board cubic prism by measurement instrument

A technology of normal direction and automatic search, applied in measuring instruments, measuring devices, instruments, etc., can solve problems such as shortening the product assembly cycle, and achieve the effect of easy engineering implementation, full automation, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings, but this is only exemplary and not intended to limit the protection scope of the present invention. Below in conjunction with accompanying drawing this patent is described further.

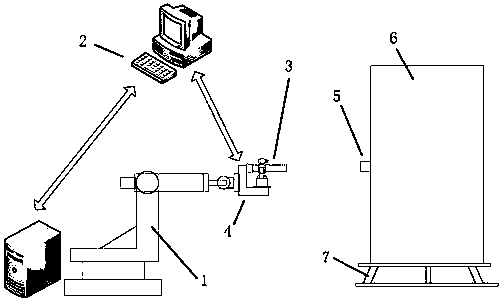

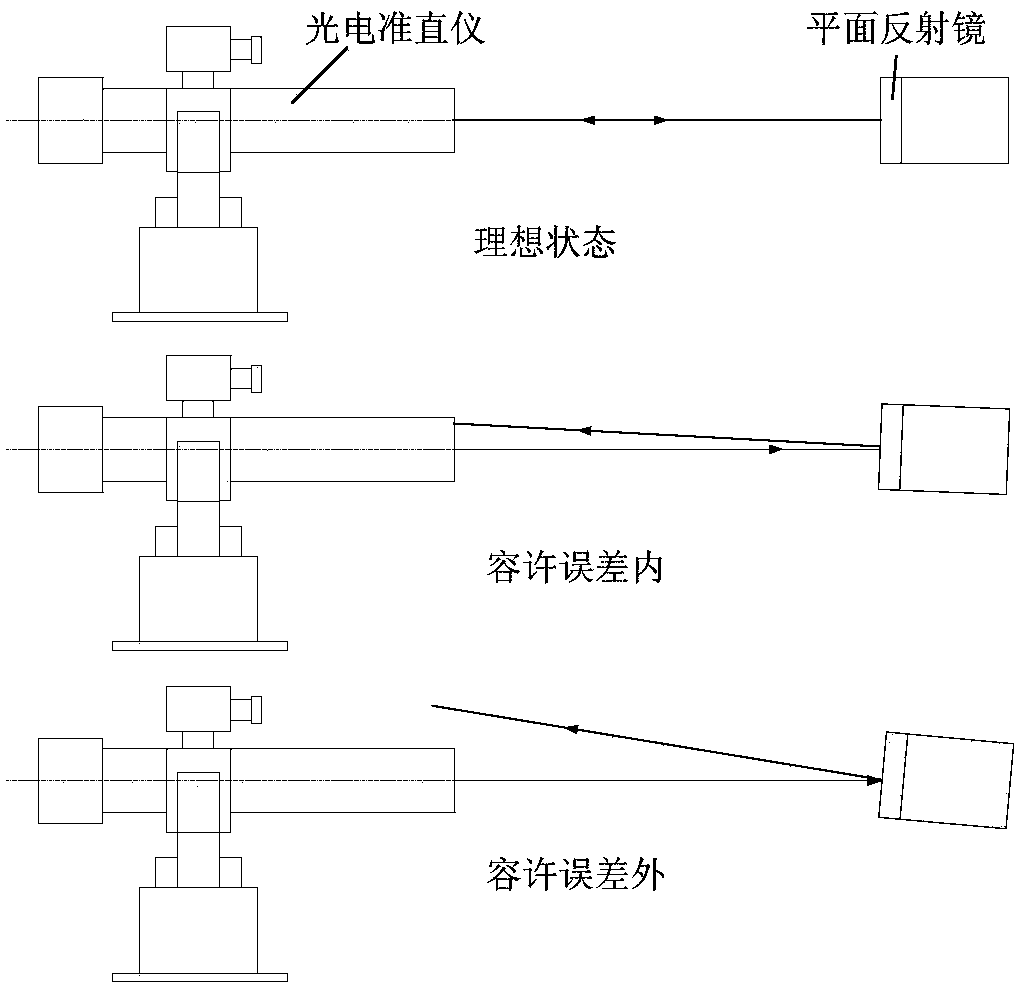

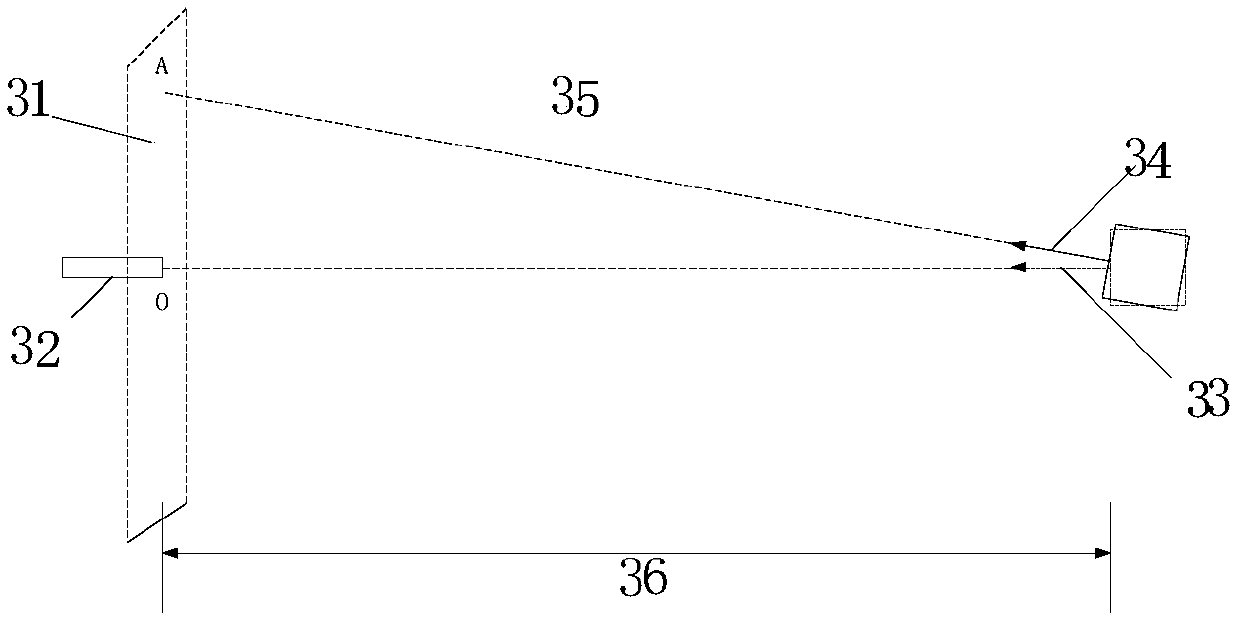

[0028] Such as figure 1 As shown, as a high-precision measuring instrument, the photoelectric collimator is basically aligned with the normal direction of the plane mirror. figure 1 As shown in the figure below), it is impossible to measure. Since the plane mirror is fixed on the spacecraft product under test, it is necessary to actively find its normal direction by a high-precision measuring instrument. Only when the optical axis of the photoelectric collimator returns to the optical axis position of the photoelectric collimator through the original path of the plane mirror on the spacecraft product under test, is the normal direction of the plane mirror completely found. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com