A Method for Detecting Structural Defects in Composite Materials Using Surface Resonance Visualization Technology

A technology for composite materials and structural defects, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves. It can solve the problems of expensive detection technology equipment and troublesome operation, and achieve the effects of intuitive pattern comparison, comprehensive detection, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for detecting structural defects of a carbon fiber reinforced composite material plate using surface resonance visualization technology, the steps are:

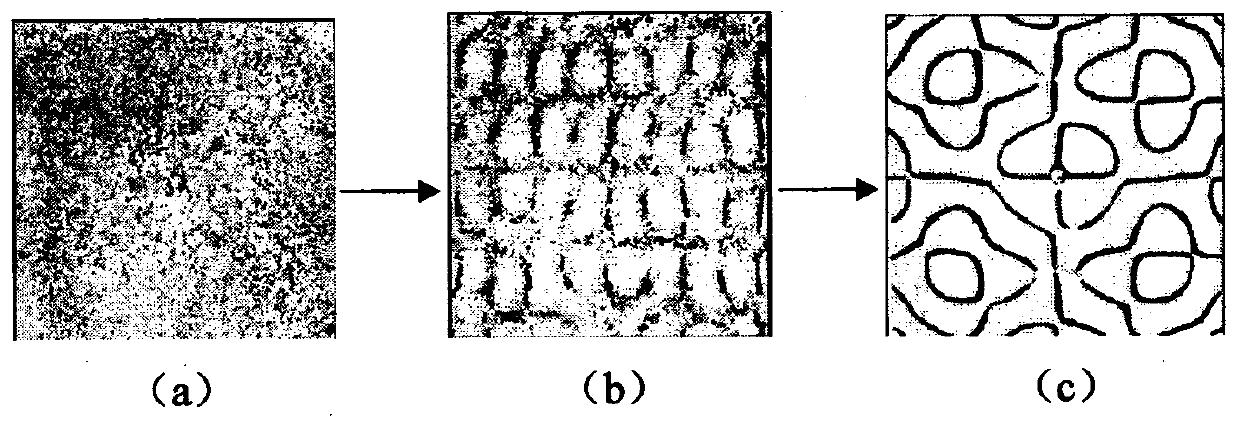

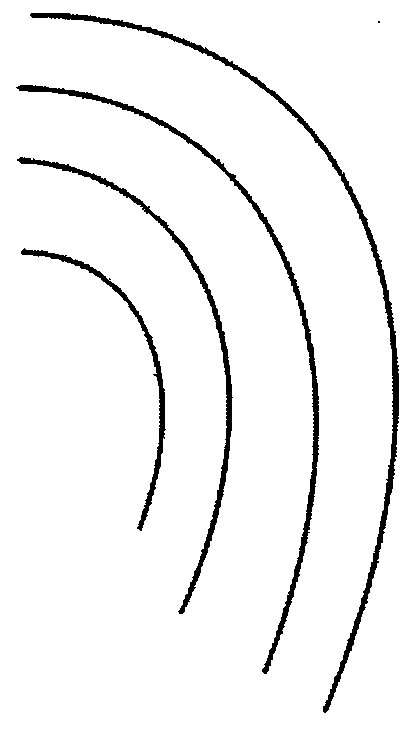

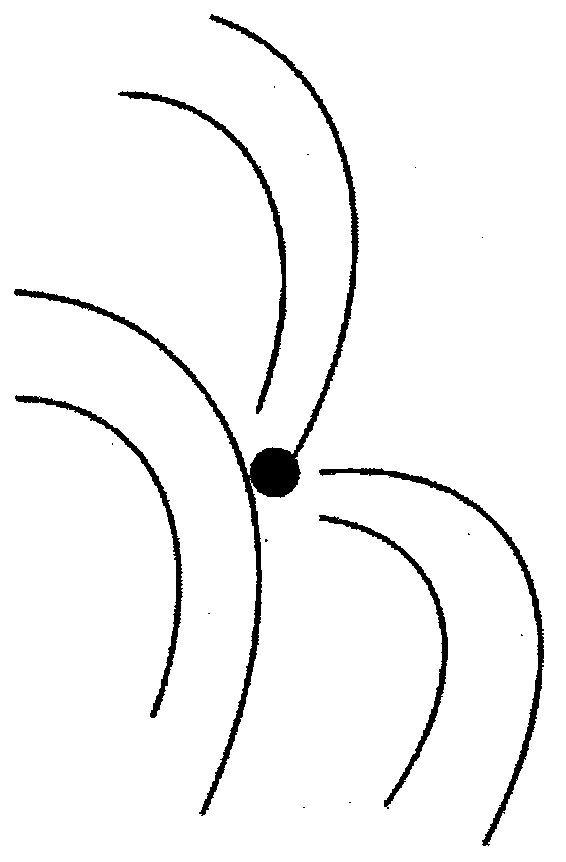

[0036] 1. The carbon fiber short fiber reinforced epoxy composite board with a length and width of 40cm×40cm and a thickness of 0.3cm is used as a standard board. Sprinkle the salt particles evenly on the surface, and use the excitation oscillator to vibrate the composite material. When the frequency of 312kHz is applied to resonate, the salt particles form a pattern on the surface of the material. figure 1 As shown, the resonance frequencies of various types of composite materials and the patterns presented at the vibration frequencies were recorded, and a vibration image library was established through simple image processing.

[0037] 2. Take a carbon fiber short fiber reinforced epoxy composite material plate with a defect length and width of 40cm×40cm and a thickness of 0.3cm as the sample to be tested. ...

Embodiment 2

[0039] A method for detecting structural defects of a glass fiber reinforced composite material plate using surface resonance visualization technology, the steps are:

[0040] 1. A glass fiber reinforced composite material board with a length and width of 35cm×35cm and a thickness of 0.3cm is used as a standard board. Sprinkle salt particles evenly on the surface, and use the excitation oscillator to vibrate the composite material. When the frequency of 108kHz is applied, resonance is generated, so that the salt particles form a pattern on the surface of the material, and the resonance frequency and frequency of various composite materials are recorded. The patterns presented at this vibration frequency can be used to establish a vibration image library through simple image processing.

[0041] 2. A glass fiber reinforced composite material plate with a length and width of 35cm×35cm and a thickness of 0.3cm is used as a sample to be tested. The same salt particles are evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com