Exposure illumination device

A technology for lighting devices and exposure surfaces, which is applied in photolithographic exposure devices, microlithography exposure equipment, optics, etc., can solve the problems of increasing substrate manufacturing costs, increasing costs, and increasing replacement frequency, achieving stable substrate exposure and improving Effects of manufacturing efficiency, securing uniformity, and sufficient illuminance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

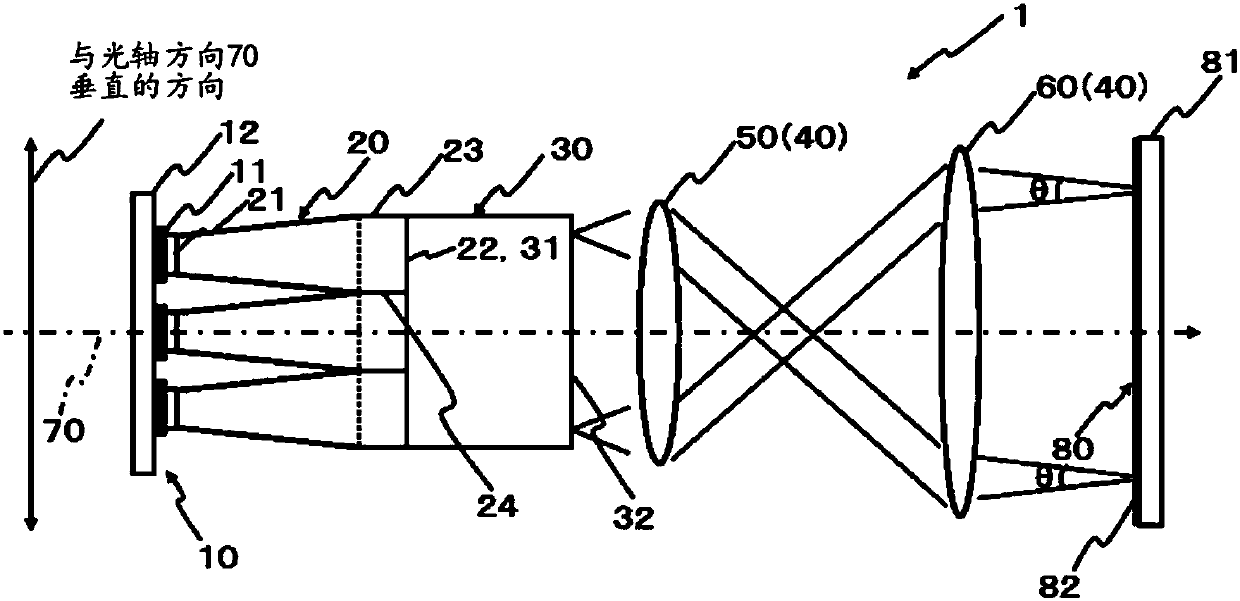

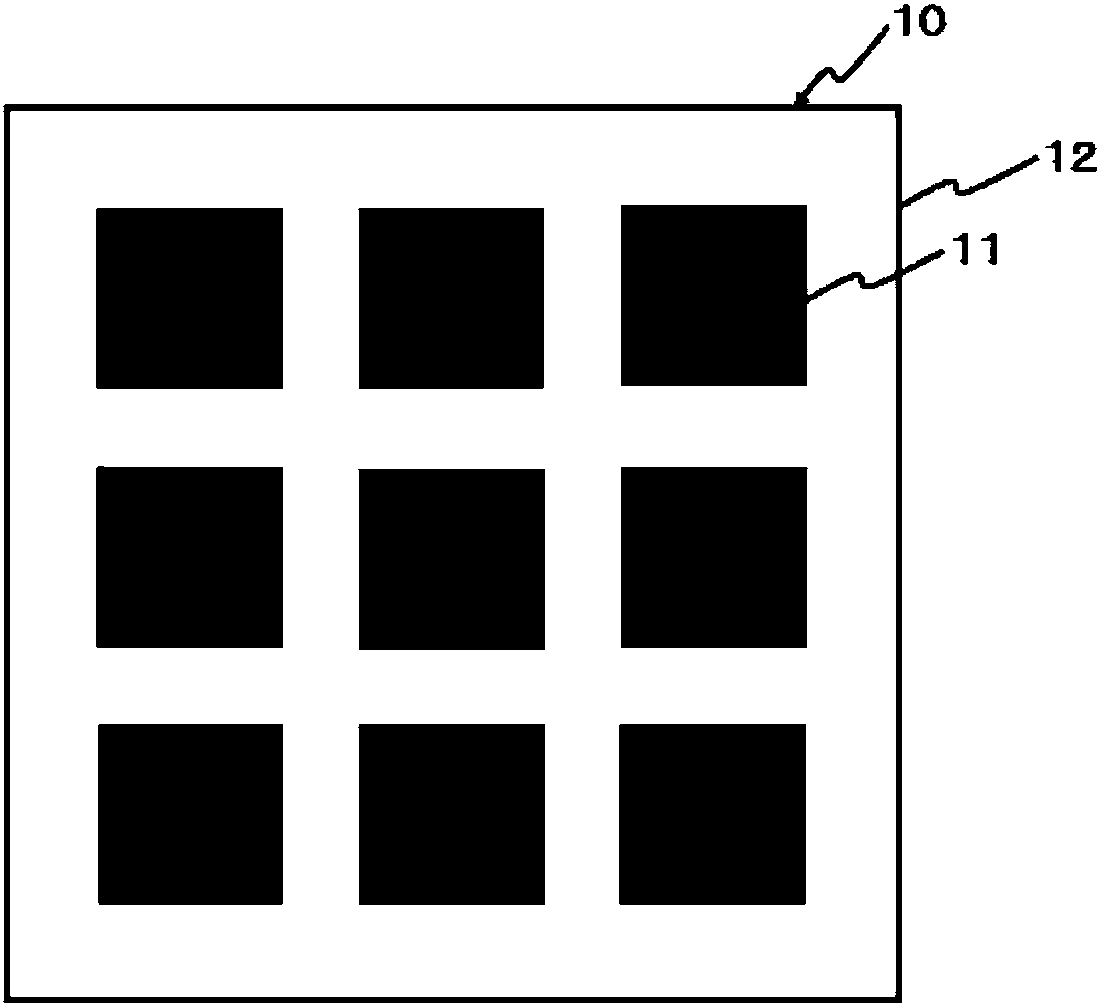

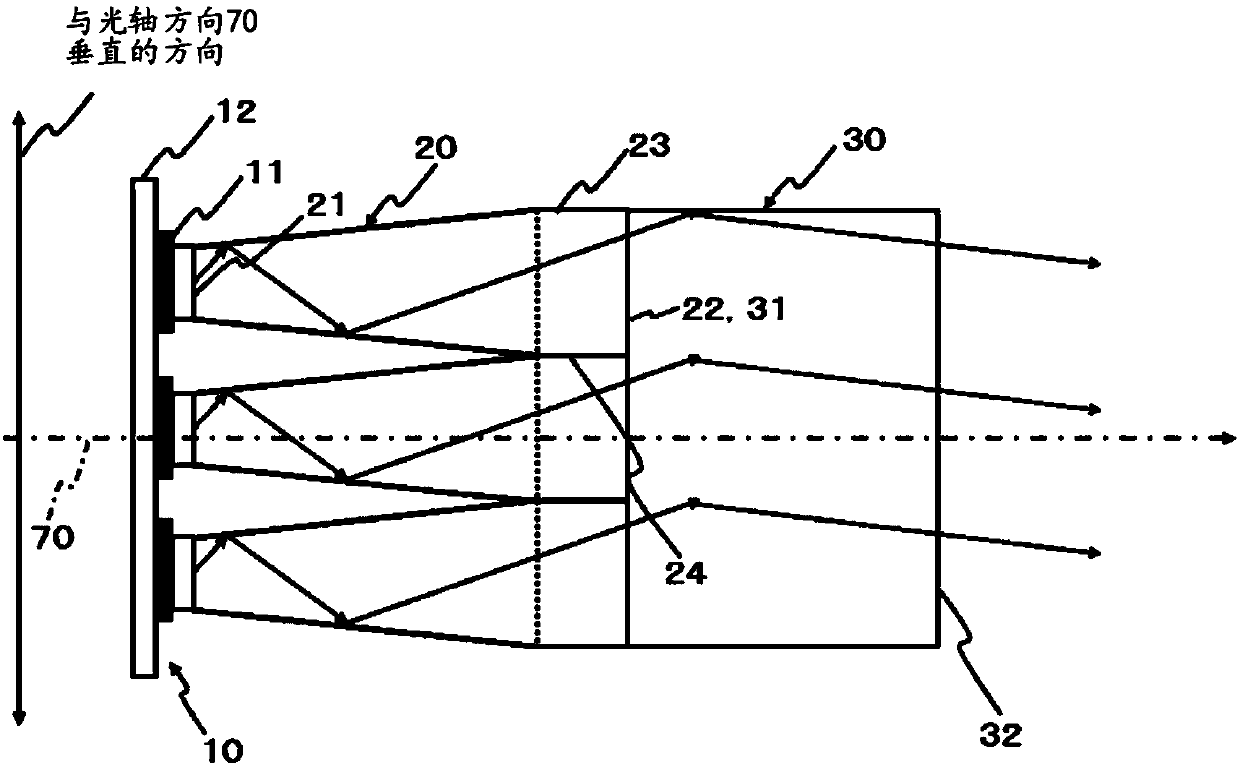

[0087] refer to Figure 1 to Figure 4 , the first embodiment of the present invention will be described in detail. figure 1 is a configuration diagram showing an outline of the overall configuration of the exposure lighting device according to the first embodiment of the present invention, figure 2 It is a front view showing the overall configuration of the light source in the exposure lighting device, image 3 It is a figure for explaining the technical effect of 1st Embodiment, Figure 4 is another diagram for explaining the technical effect of the first embodiment, Figure 4 The oblique line in □ indicates that a large surface light source is formed on the output end surface 22 of the first light guide 20 and the light beam is output.

[0088] refer to figure 1 The outline of the exposure lighting device of the present invention will be described. The exposure lighting device 1 has a light source 10, a first light guide body 20, a second light guide body 30, and an ...

no. 2 Embodiment approach

[0101] Next, refer to Figure 5 , the second embodiment of the present invention will be described in detail. In the description of the second embodiment, the configurations assigned the same reference numerals as those in the first embodiment described above will be regarded as the same configurations, and their descriptions will be omitted.

[0102] An example in which the position of the second light guide is changed is shown for the exposure lighting device 2 of the second embodiment. That is to say, in the second embodiment, the optical member 400 is provided between the first light guide 20 and the second light guide 200, and the second light guide 200 is refracted by the optical member 400 and converged from the first light guide. The light beam emitted by the light body 20 is used to reduce the light beam and make it incident.

[0103]Similar to the first embodiment described above, the second light guide 200 is a rod. More specifically, the second light guide 200 i...

no. 3 Embodiment approach

[0108] Next, refer to Figure 6 , the third embodiment of the present invention will be described in detail. In the description of the third embodiment, the configurations assigned the same reference numerals as those in the first embodiment and the second embodiment described above will be regarded as the same configurations and their description will be omitted.

[0109] The example which changed the structure of the 2nd light guide in 2nd Embodiment is shown about the exposure illumination apparatus 3 of this 3rd Embodiment. That is, in the third embodiment, the second light guide 300 is a compound eye and is formed of synthetic quartz or the like. More specifically, in the second light guide 300, a first compound eye 301a formed by a plurality of lenses 301b is provided on the incident end surface 301 side, and a second compound eye 302a formed by a plurality of lenses 302b is provided on the exit end surface 302 side. The optical device is configured to refract and conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com