Electric wire surface treatment equipment

A technology for surface treatment and power wires, which is applied in the field of power wire surface treatment equipment, can solve problems affecting performance, corrosion, product quality and quality impact, etc., and achieve the effects of improving use efficiency, ensuring spray quality, and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

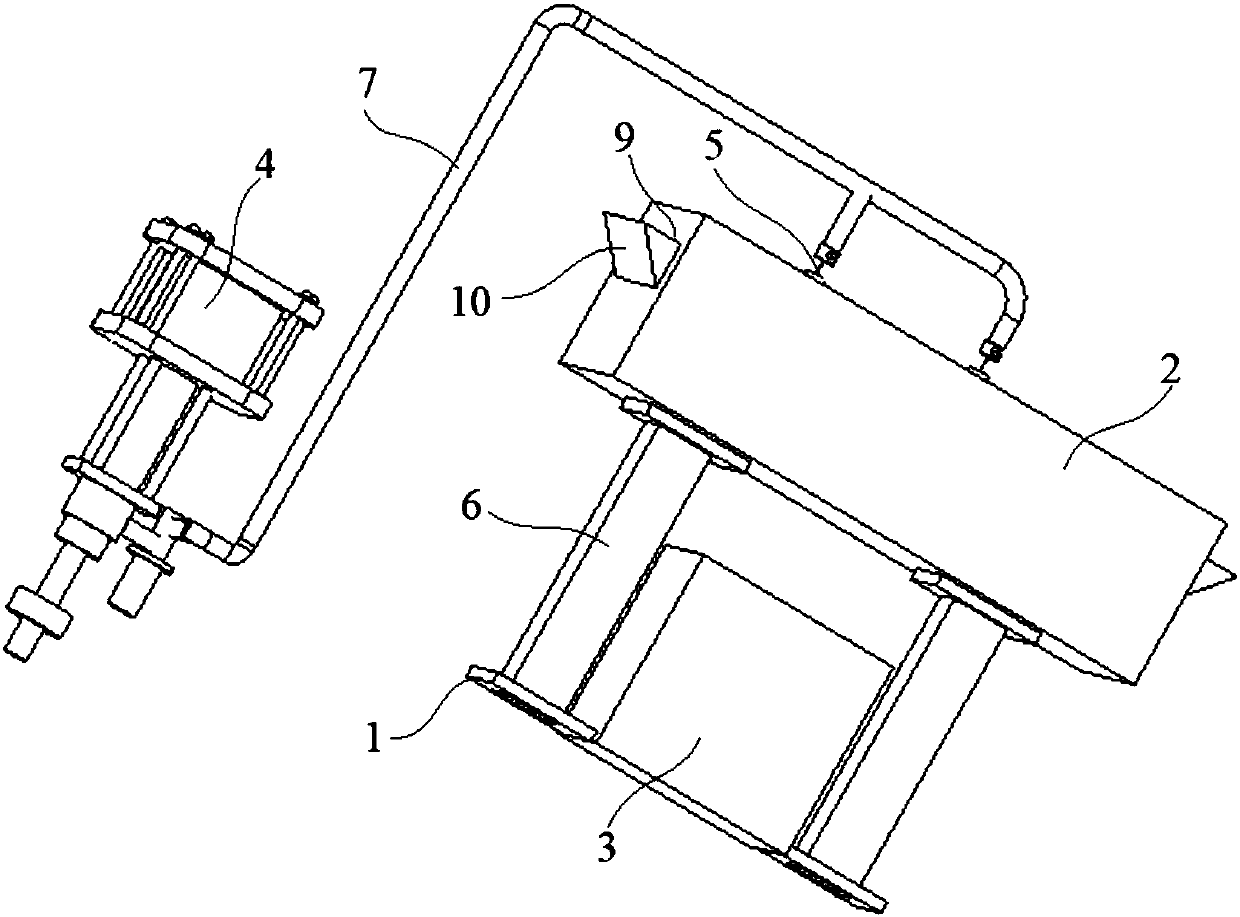

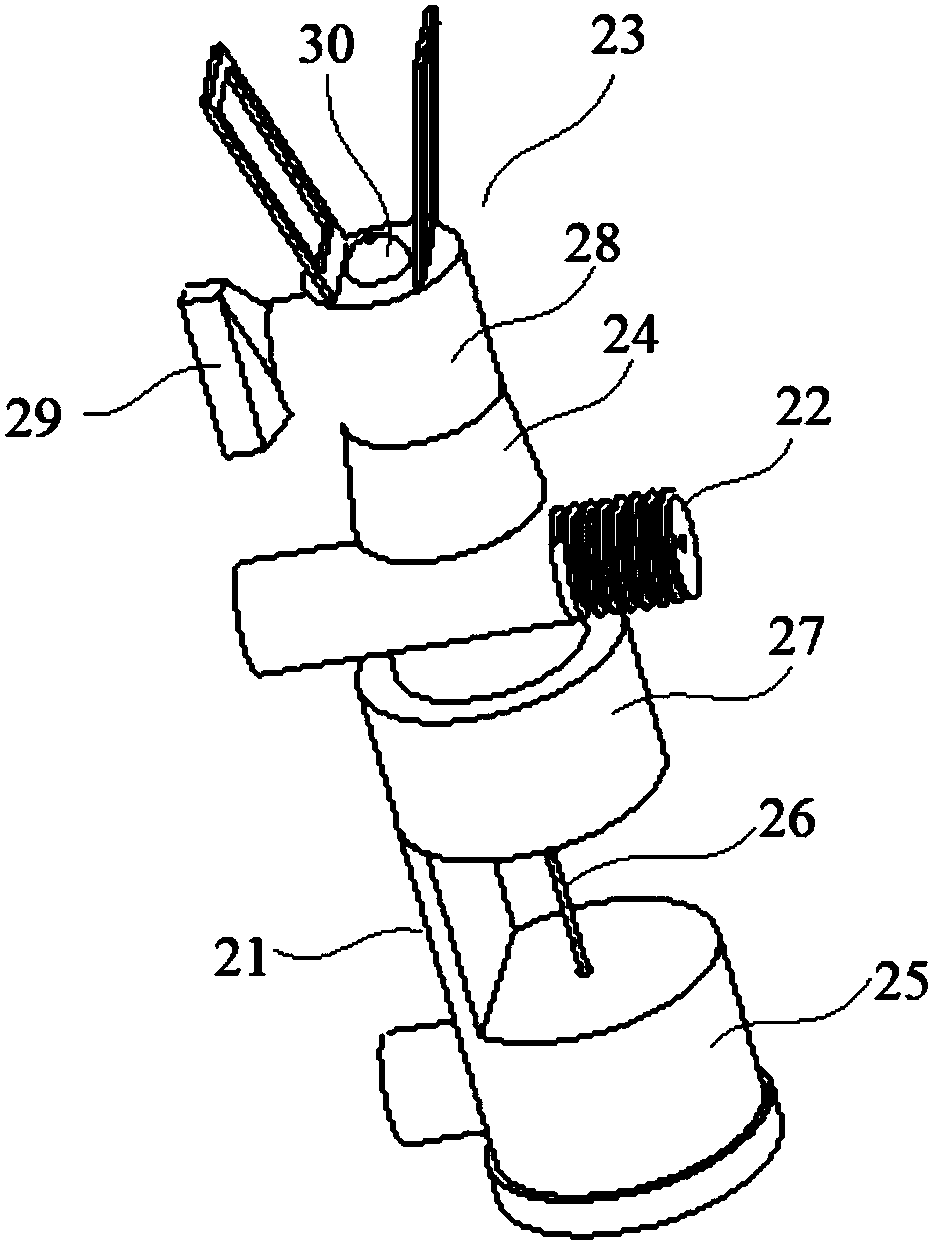

[0023] Embodiment 1: A surface treatment equipment for electric wires, including a bottom plate 1, a wire passing box 2, an oil tank 3, a high-pressure gasification device 4 and several nozzles 5, and the wire passing box 2 is fixedly installed on the bottom plate 1 through several supports 6 On the upper surface, the fuel tank 3 is movably arranged directly below the cable box 2, the fuel tank 3 is connected to the high-pressure gasification device 4 through a hose 7, and the high-pressure gasification device 4 is respectively connected to several nozzles 5 through the hose 7 connected, the plurality of nozzles 5 are installed on the wiring box 2;

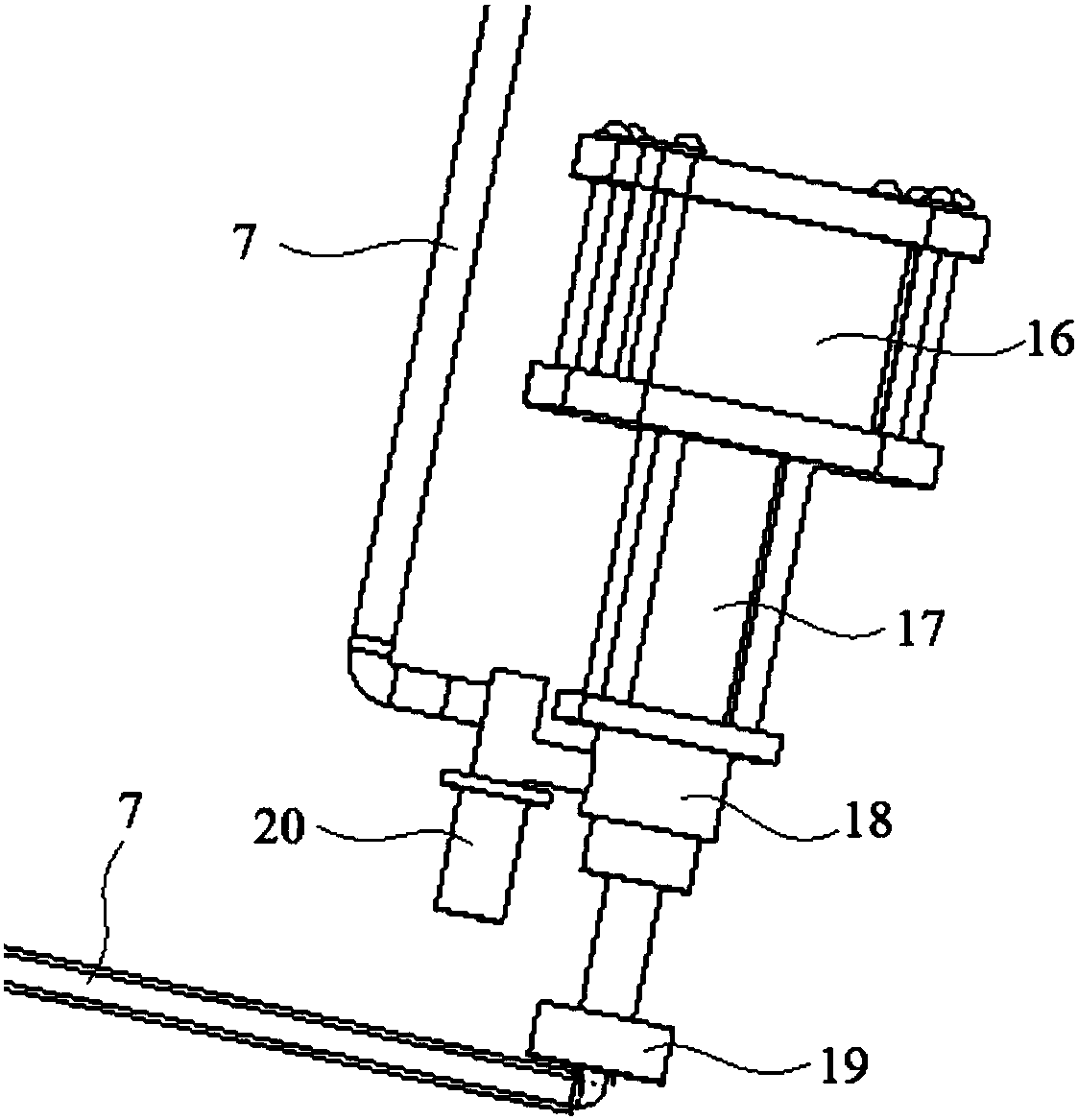

[0024] The high-pressure gasification device 4 is composed of a cylinder block 16, a piston rod 17, an oil chamber 18, an oil filter 19 and a water filter 20. One end of the piston rod 17 is embedded in the cylinder block 16 and reciprocated One end of the oil chamber 18 is connected to the piston rod 17, the other end of the oil ...

Embodiment 2

[0028] Embodiment 2: A surface treatment equipment for electric wires, including a bottom plate 1, a wire passing box 2, an oil tank 3, a high-pressure gasification device 4 and several nozzles 5, and the wire passing box 2 is fixedly installed on the bottom plate 1 through several supports 6 On the upper surface, the fuel tank 3 is movably arranged directly below the cable box 2, the fuel tank 3 is connected to the high-pressure gasification device 4 through a hose 7, and the high-pressure gasification device 4 is respectively connected to several nozzles 5 through the hose 7 connected, the plurality of nozzles 5 are installed on the wiring box 2;

[0029] The high-pressure gasification device 4 is composed of a cylinder block 16, a piston rod 17, an oil chamber 18, an oil filter 19 and a water filter 20. One end of the piston rod 17 is embedded in the cylinder block 16 and reciprocated One end of the oil chamber 18 is connected to the piston rod 17, the other end of the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com