Simulation podocarpus macrophyllus manufacturing device

A manufacturing device and a technology of rhododendron, applied in artificial flowers, clothing, applications, etc., can solve the problems of high manufacturing cost and labor time-consuming, and achieve the effects of reducing manufacturing cost, beautiful appearance, and three-dimensional modeling diversity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] Option One:

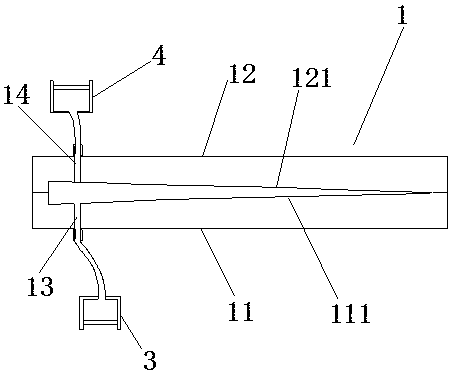

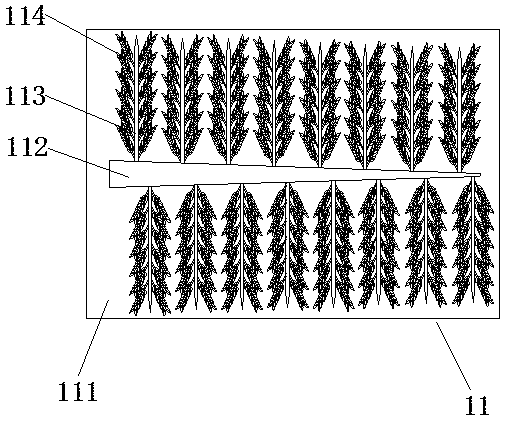

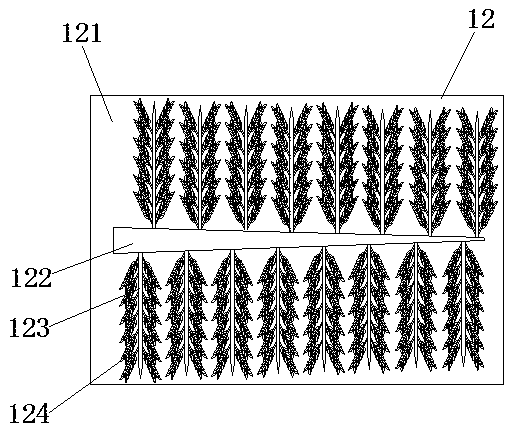

[0026] A simulated Podocarpus pine manufacturing device includes a plate-shaped plastic molding device 1 and a thermal molding device 2; the plate-shaped plastic mold device 1 is shown in Figure 1, Figure 2 and image 3 As shown, it includes a first template 11 and a second template 12; the upper side of the first template 11 is the first mold surface 111, the lower side of the second template 12 is the second mold surface 121, and the first mold surface 111 Butted with the second mold surface 121, the first mold surface 111 is distributed with a first stem-shaped groove 112, a first branch-shaped groove 113 and a first leaf-shaped groove 114, and the first stem-shaped groove 112 is connected with at least two second A branch-shaped groove 113, each first branch-shaped groove 113 is connected with at least two first leaf-shaped grooves 114; the second mold surface 121 is distributed with a second stem-shaped groove 122, a second branch-shaped groove 123 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com