Water flow bubble sorting method and system of mixed granular materials

A sorting system and a technology for mixing materials, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as incomplete sorting, achieve good sorting effect, fast separation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

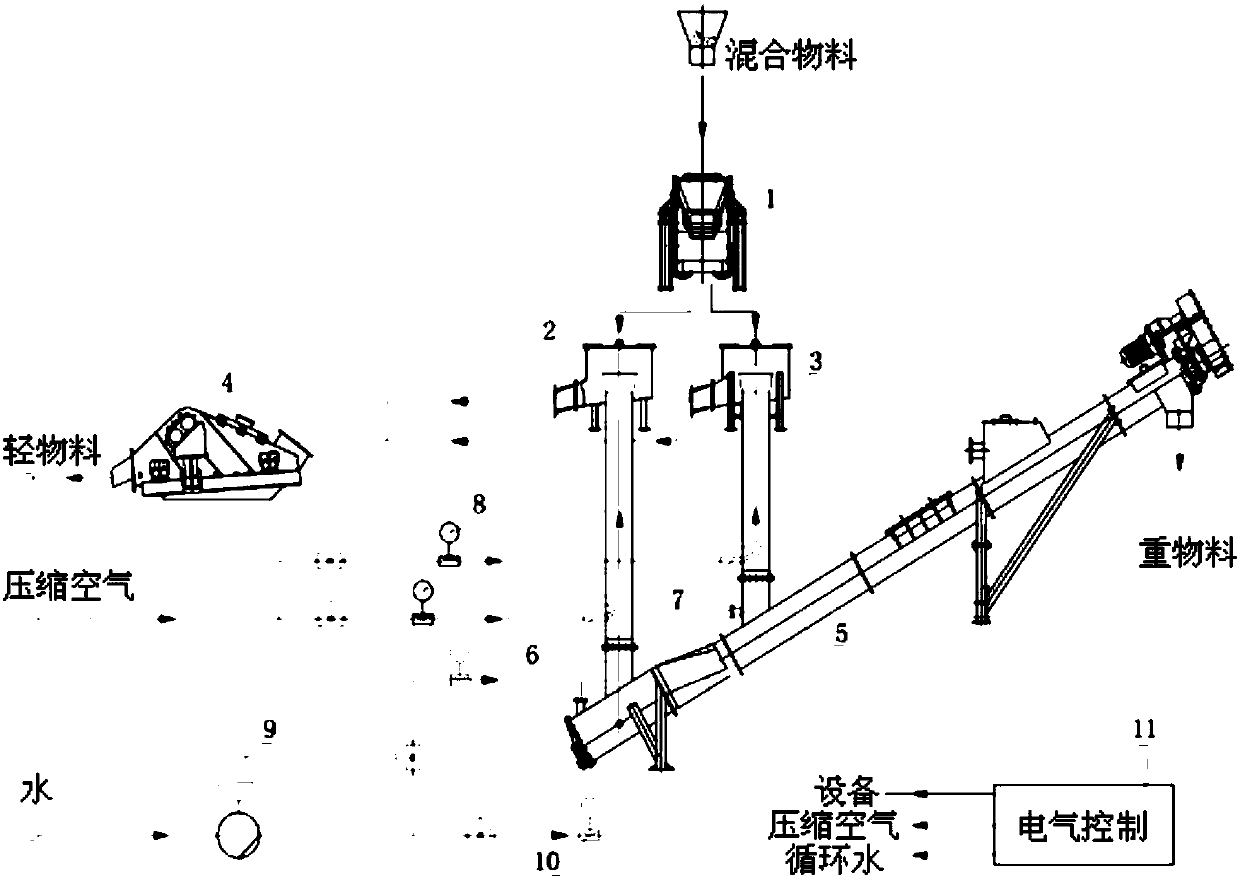

[0043] The present invention will be described in detail below in conjunction with the drawings and specific implementation steps:

[0044] The mixed material first enters the linear vibrating screen 1 of the water flow bubble sorting system (hereinafter referred to as the sorting system) of the mixed granular material for sorting, and the diameter is larger than d s And less than or equal to d s Material (d s Preferably 10mm) are selected respectively, and then respectively enter the hydrodynamic separator I2 and the hydrodynamic separator II3.

[0045] The rising water flow speed and the amount of tiny bubbles in the hydrodynamic separator I2 (the bubbles are generated by the bubble generator I6 connected to the lower part of the hydrodynamic separator I 2) can be adjusted separately. The mixture of large particles (greater than d) s ) The separation is carried out in two media of rising water flow and air bubbles. Materials with a large specific gravity sink and materials with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com