Drilling system of belt pulley

A pulley, drilling platform technology, applied in boring/drilling, drilling/drilling equipment, clamping and other directions, can solve the problems of labor consumption, reduced work efficiency, complicated operation, etc., to reduce labor, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

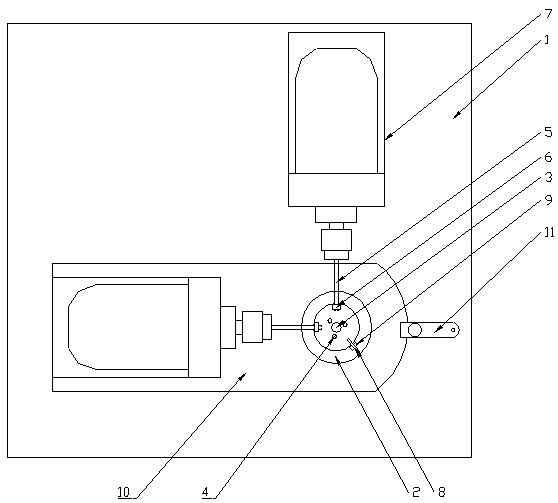

[0020] Such as figure 1 A belt pulley drilling system is shown, which is used for drilling the belt pulley, including

[0021] A drilling support, the drilling support is a cuboid frame structure composed of several cross bars and longitudinal bars, and a drilling platform 1 is installed on the upper end of the drilling support.

[0022] A positioning unit, the positioning unit includes a positioning seat 2 installed on the upper end of the drilling platform 1, and a positioning column 3 vertically arranged on the upper end of the positioning seat 2 to accommodate the middle position of the pulley, and around the positioning column 3 Several positioning pillars 4 corresponding to the lightening holes on the pulley are provided.

[0023] On the side end of the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com