Antifouling titanium alloy turbine blade and preparation method thereof

A steam turbine blade and titanium alloy technology, which is applied to mechanical equipment, blade support elements, engine elements, etc., can solve problems such as affecting the working efficiency of steam turbine blades, corroding steam turbine blades, and breaking steam turbine blades, so as to improve the blocking effect and improve adhesion. power, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

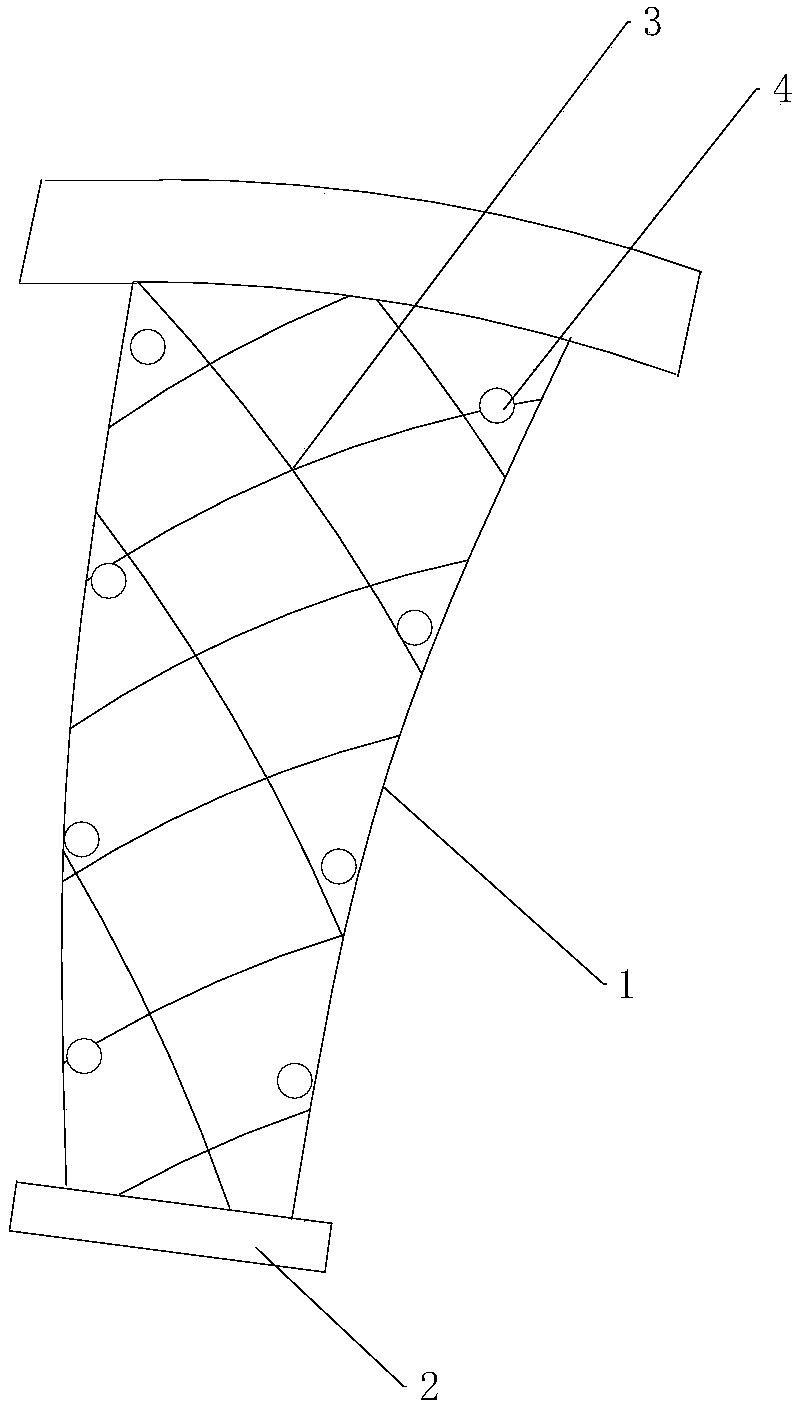

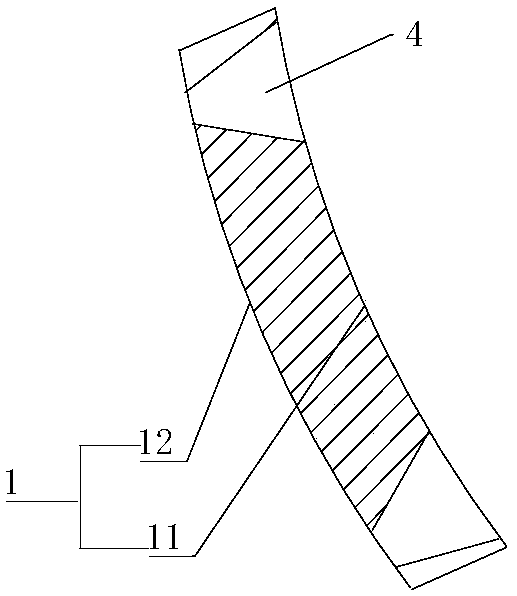

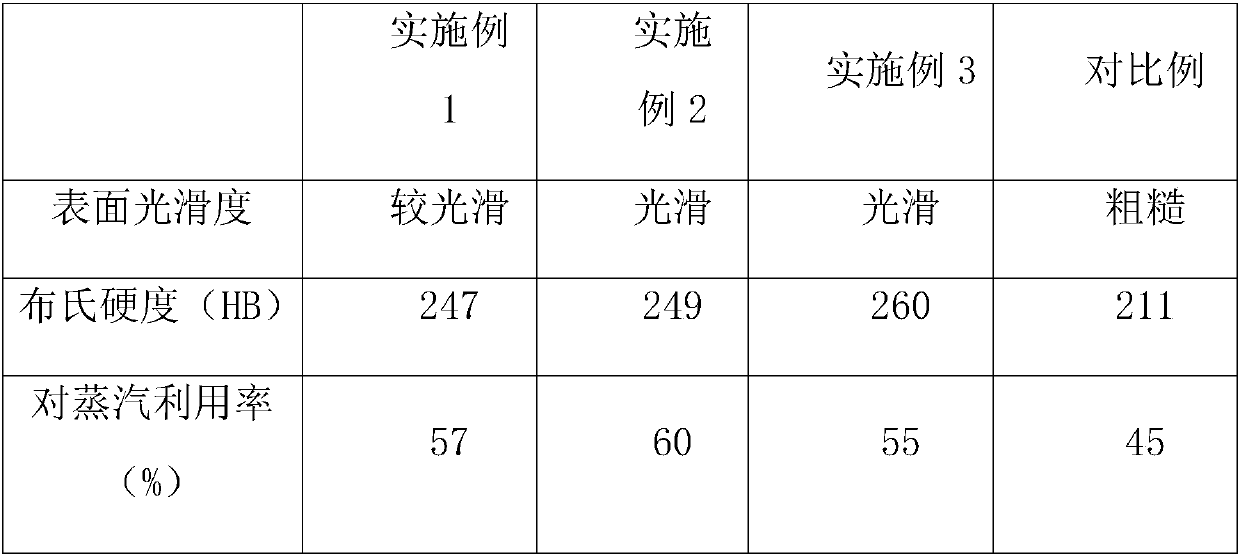

[0027] Embodiment 1: This embodiment provides a kind of antifouling titanium alloy steam turbine blade, as figure 1 and 2 As shown, including the blade body 1 and the blade root 2, the blade body 1 includes an inner arc surface 11 and an outer arc surface 12, and the inner arc surface 11 is provided with a rough surface 3, and the blade body 1 is arranged along its long side direction. A plurality of small holes 4, the small holes 4 are in the shape of a truncated cone, and the bottom surface of the truncated small holes 4 is arranged close to the inner arc surface 11.

[0028] The chemical composition and mass percentage of the steam turbine blade are as follows: C: 3.3%, Si: 0.2%, Mn: 0.2%, P: 0.01%, S: 0.01%, Ni: 0.2%, V: 0.35%, Mo: 0.02 %, Ti: 0.04%, ZnO: 0.05%, Cu: 0.7%, TiN: 0.2%, TiAlN: 0.03%, CrN: 0.09%, the total amount is 0.01% of Cr and Co, and the balance is Fe.

[0029] Wherein, the particle size of ZnO and Cu powders is 7-35 μm.

[0030] A preparation method f...

Embodiment 2

[0037] Embodiment 2: This embodiment provides a kind of antifouling titanium alloy steam turbine blade, as figure 1 and 2 As shown, including the blade body 1 and the blade root 2, the blade body 1 includes an inner arc surface 11 and an outer arc surface 12, and the inner arc surface 11 is provided with a rough surface 3, and the blade body 1 is arranged along its long side direction. A plurality of small holes 4 are in the shape of a truncated cone, and the bottom surface of the small holes 4 in the shape of a truncated cone is arranged close to the inner arc surface 11 .

[0038] The chemical composition and mass percentage of the steam turbine blade are as follows: C: 3.9%, Si: 0.3%, Mn: 0.9%, P: 0.09%, S: 0.04%, Ni: 0.25%, V: 0.36%, Mo: 0.03 %, Ti: 0.05%, ZnO: 0.27%, Cu: 0.73%, TiN: 0.7%, TiAlN: 0.04%, CrN: 0.1%, the total amount is 0.2% of Cr and Co, and the balance is Fe.

[0039] Wherein, the particle size of the ZnO and Cu powders is 7-35 μm.

[0040] A preparation...

Embodiment 3

[0047] Embodiment 3: This embodiment provides a kind of antifouling titanium alloy steam turbine blade, as figure 1 and 2 As shown, including the blade body 1 and the blade root 2, the blade body 1 includes an inner arc surface 11 and an outer arc surface 12, and the inner arc surface 11 is provided with a rough surface 3, and the blade body 1 is arranged along its long side direction. A plurality of small holes 4 are in the shape of a truncated cone, and the bottom surface of the small holes 4 in the shape of a truncated cone is arranged close to the inner arc surface 11 .

[0048] The chemical composition and mass percentage of the steam turbine blade are as follows: C: 4.2%, Si: 3.6%, Mn: 1.1%, P: 0.1%, S: 0.05%, Ni: 3.0%, V: 0.38%, Mo: 0.04 %, Ti: 0.6%, ZnO: 0.3%, Cu: 0.95%, TiN: 0.9%, TiAlN: 1.1%, CrN: 0.2%, the total amount is 0.3% of Cr and Co, and the balance is Fe.

[0049] Wherein, the particle size of the ZnO and Cu powders is 7-35 μm.

[0050] A preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com