Battery detection method

一种电池检测、电池的技术,应用在测量电、测量装置、测量电变量等方向,能够解决校准平台数量有限、电池来料不固定、很快关机等问题,达到可靠性和实时性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

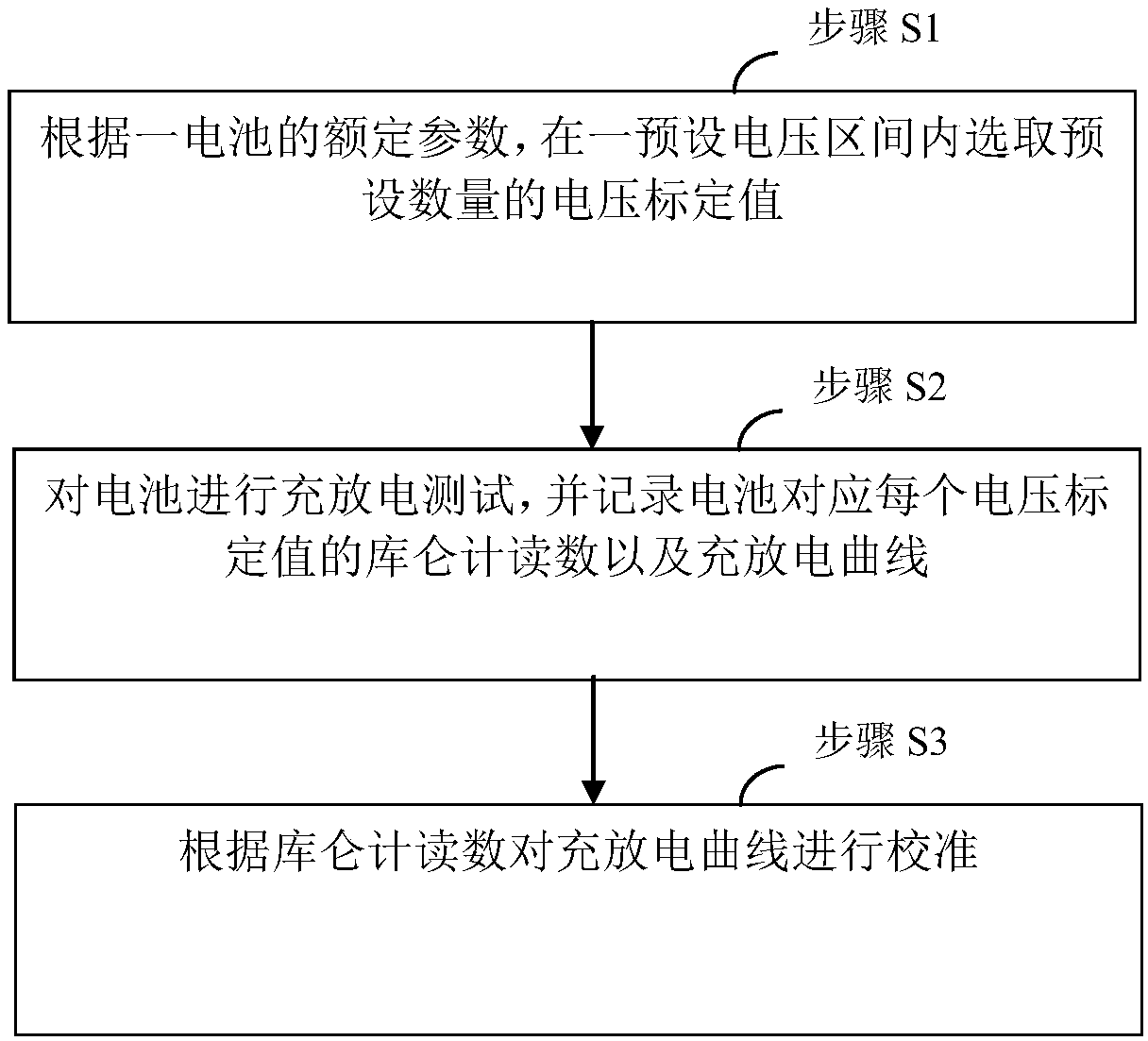

[0022] In a preferred embodiment, as figure 1 As shown, a battery detection method is proposed, which may include:

[0023] Step S1, according to the rated parameters of a battery, select a preset number of voltage calibration values within a preset voltage range;

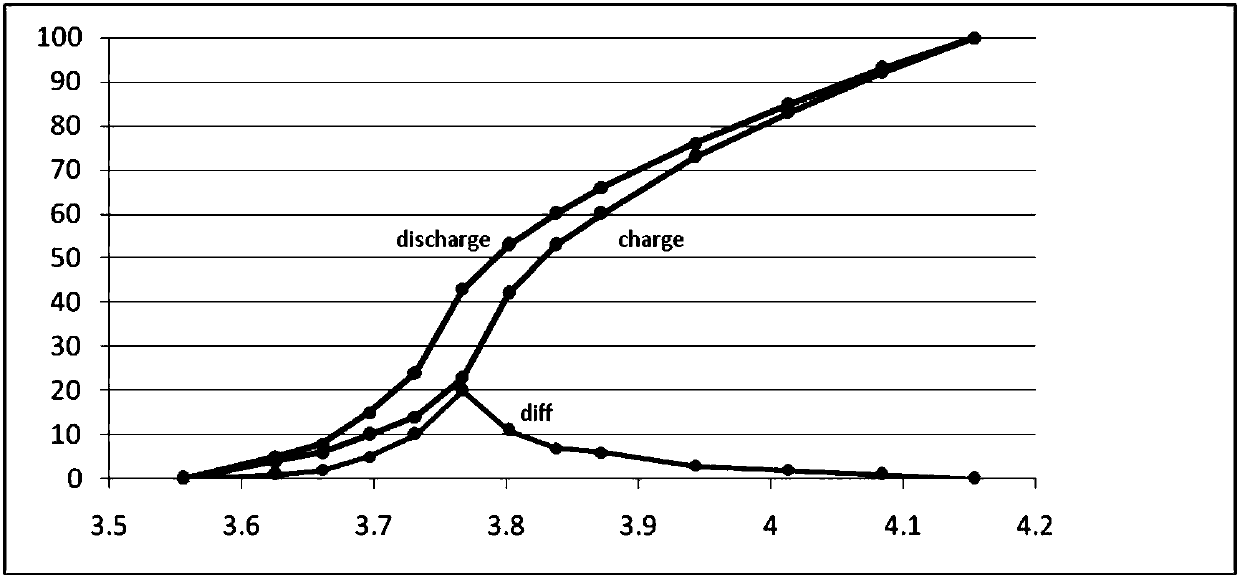

[0024] Step S2, performing a charge and discharge test on the battery, and recording the coulomb counter readings and charge and discharge curves of the battery corresponding to each voltage calibration value;

[0025] In step S3, the charging and discharging curve is calibrated according to the reading of the coulomb counter.

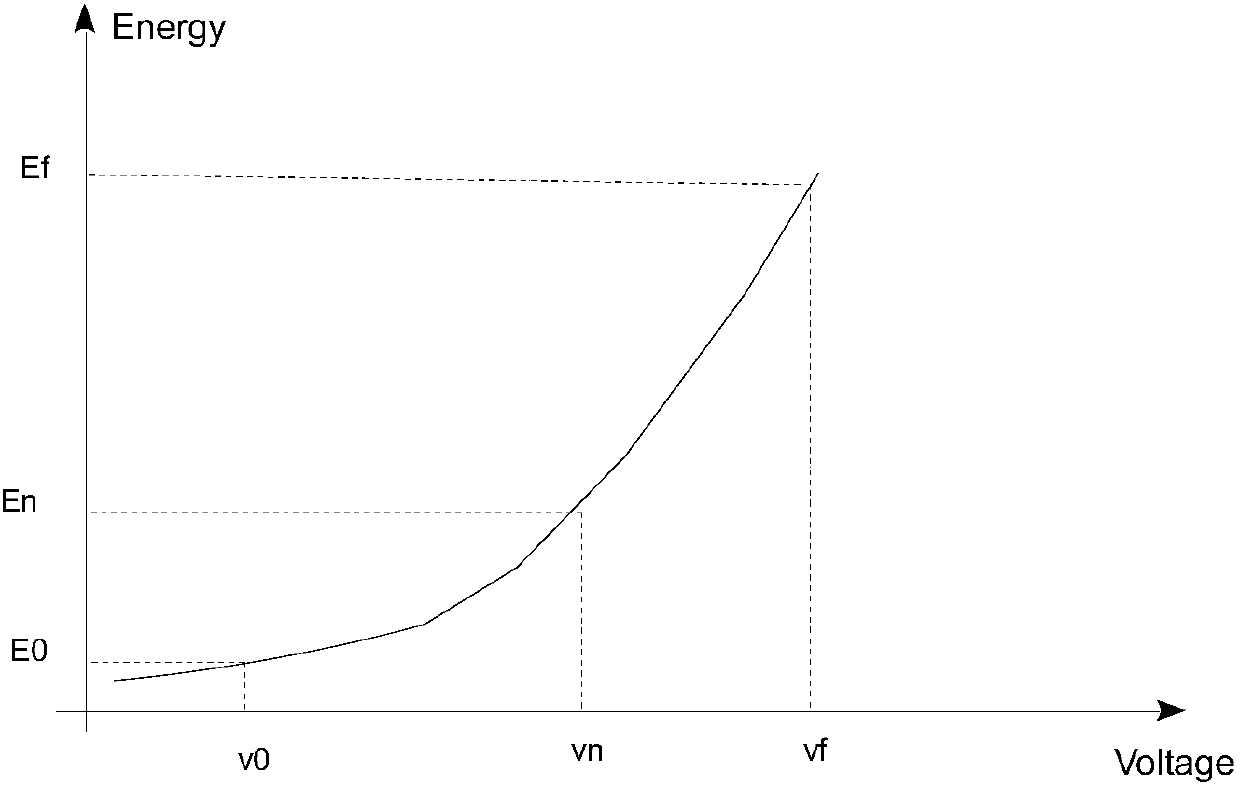

[0026] In the above technical solution, the power P=U*I, where U is the voltage and I is the current. For example, when the battery voltage is 3.0v, the battery is charged with a current of 1A, and when the battery voltage reaches 4V, the battery is charged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com