Design method for variable relative density octet lattice structure

A technique of lattice structure and relative density, which is applied in the design of variable relative density octet lattice structure and the field of mechanical performance design, and can solve the problem of complex realization and solution process of homogenized topology optimization, and the application potential of variable relative density three-dimensional lattice structure. Fully understood, less research on optimal design methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

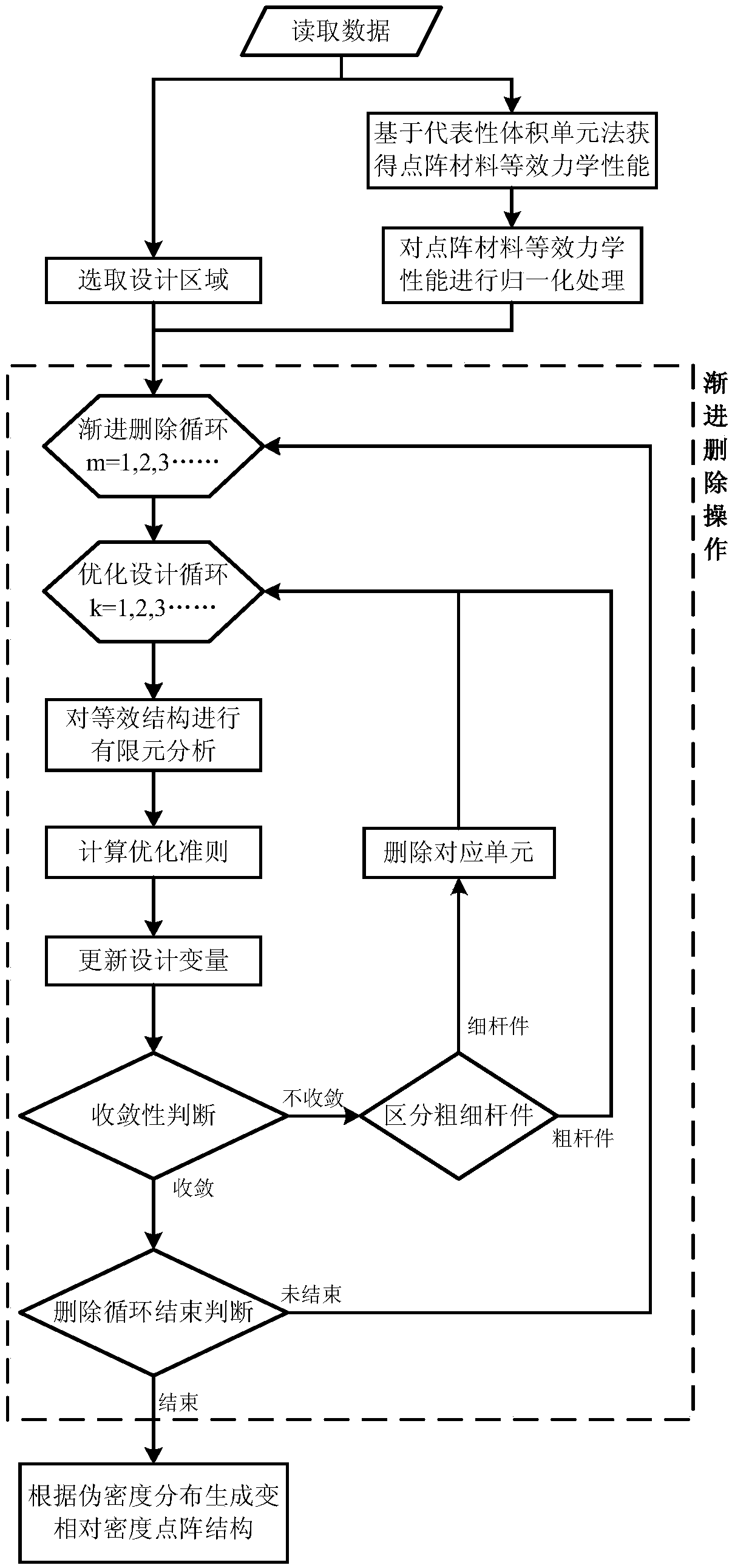

Method used

Image

Examples

Embodiment 1

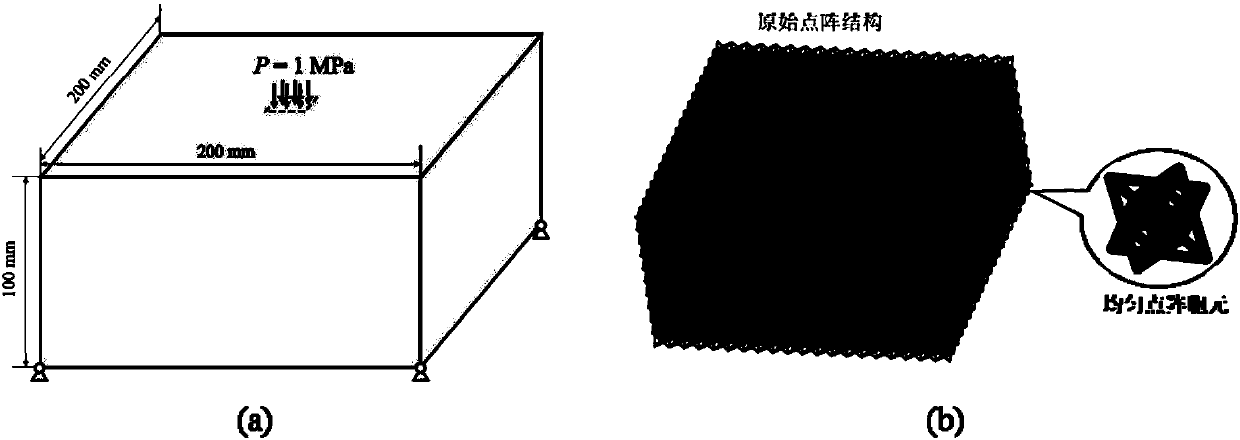

[0102] Embodiment 1: Optimization of the rectangular parallelepiped octet lattice structure supported by four corners

[0103] image 3 It is a schematic diagram of the structure size and loading method of a cuboid octet lattice supported by four corners, and the number of units on each side is 20×20×10. Material Young's modulus E s is 1000Pa, Poisson's ratio υ is 0.33. The relative density of the original uniform lattice structure is 0.2666 (corresponding to the rod slenderness ratio of 0.1), and the material volume fraction VR is 0.0933.

[0104] 1. In this example, the four corners of the bottom are 10×10mm 2 Constrain displacement within the range, 10×10mm at the top center 2 Apply a vertical downward surface load P=1MPa within the range.

[0105] 2. Based on the finite element software ANSYS, the finite element analysis model of the lattice structure is established and the finite element analysis is carried out. In the calculation process of this example, the orth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com