A gripper and a gripping method for replacing detector components

A detector assembly and gripper technology, which is applied to reactor fuel elements, greenhouse gas reduction, reactors, etc., can solve problems such as increased environmental dose occupational exposure, low detector assembly efficiency, etc., to reduce the number of operators and reliability. High and efficient work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

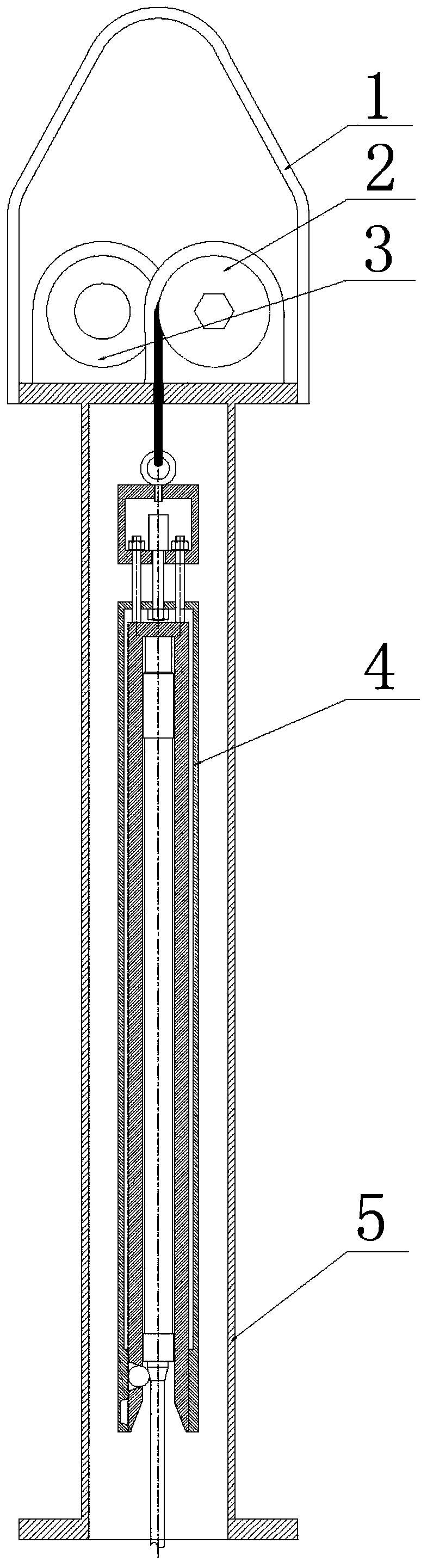

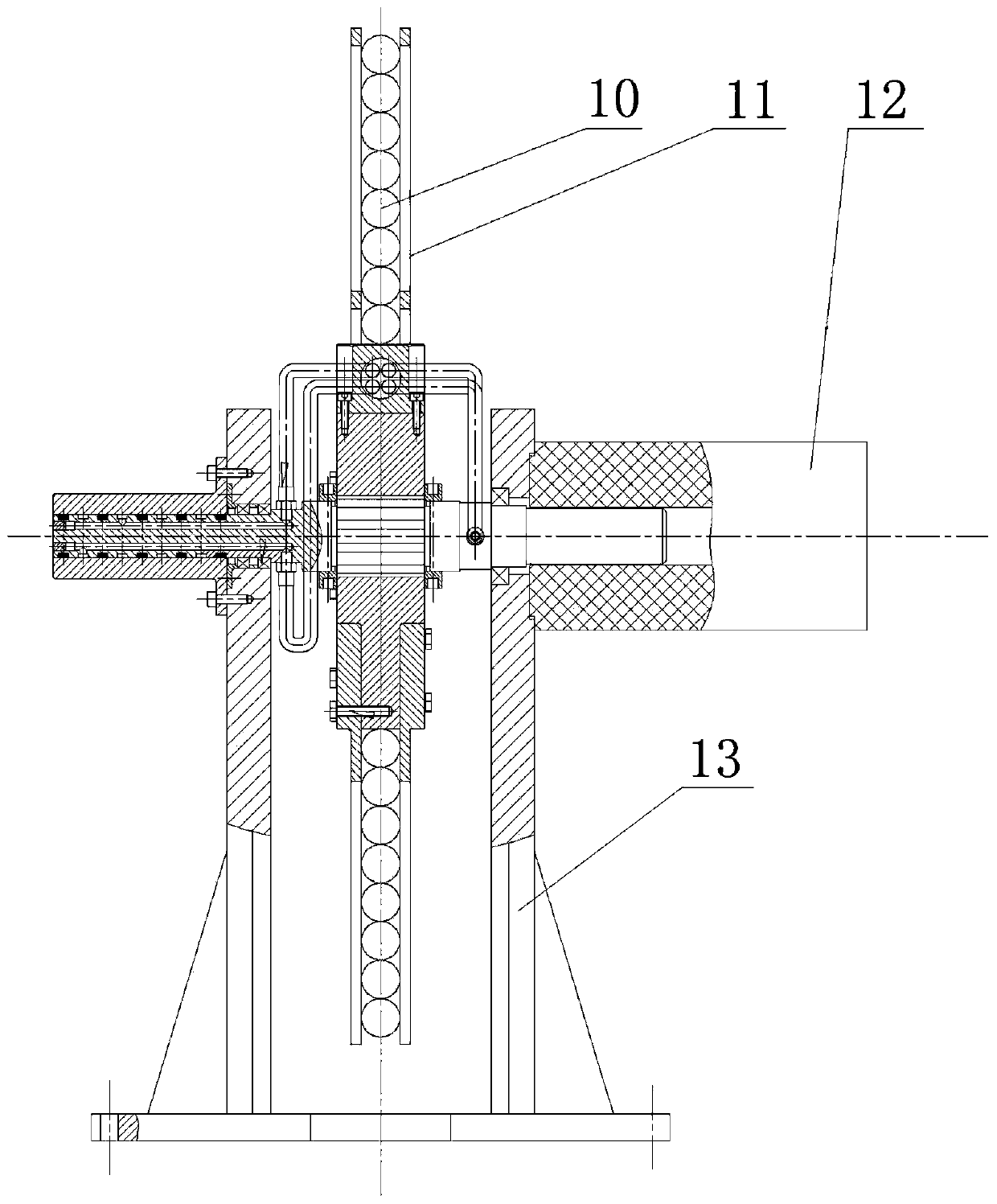

[0025] Such as Figure 4 As shown, a gripper for replacement of a detector assembly includes a gripper body 4, which is mainly composed of a sleeve 19, a support tube 20, a power mechanism 16 and a locking mechanism 22, wherein the power mechanism 16 is arranged above the sleeve 19 and connected with the sleeve 19. The sleeve 19 is sleeved outside the support cylinder 20 and can move along the outer wall of the support cylinder 20 under the action of the power mechanism 16, and the locking mechanism 22 follows the movement of the sleeve 19 It can be switched between the sleeve 19 and the support cylinder 20. The detector assembly can be grasped, lifted and transported in a high-radioactive water environment through remote operation. The grasping head of the multi-layer sleeve combined with the ball locking mechanism is used to grasp the detector assembly. The structure is simple and compact, which is suitable for the detector in a small space. Component to operate.

Embodiment 2

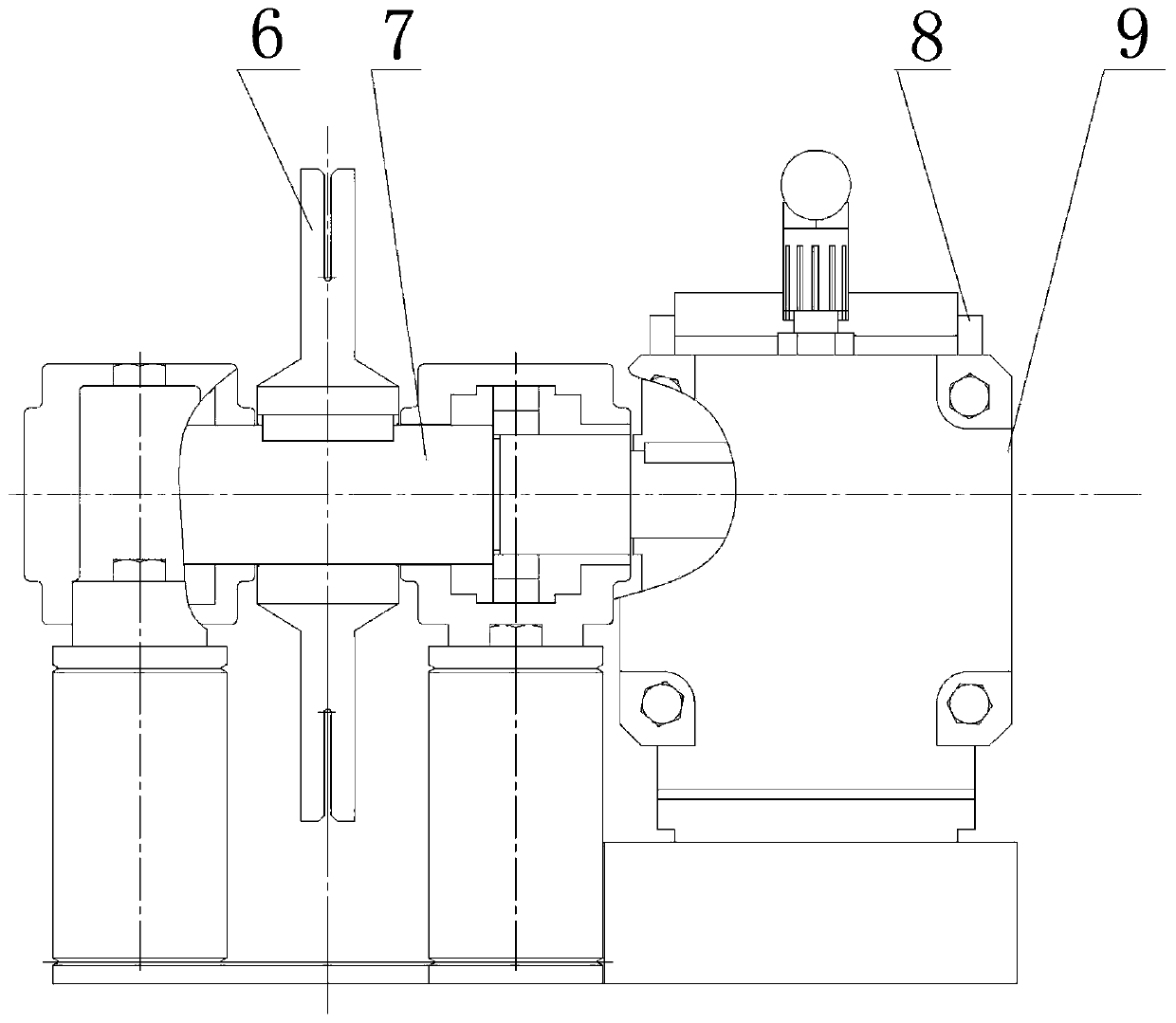

[0027] Such as Figure 1 to Figure 4 On the basis of embodiment 1, the hardware structure is: the power mechanism 16 is preferably a cylinder, the locking mechanism 22 is three steel balls, and the adjacent steel balls are arranged at 120°, and the piston rod of the cylinder is connected to the lower cylinder 18 Connected, the top of the support cylinder 20 passes through the lower cylinder 18 and is arranged in the lower cylinder 18, and the lower cylinder 18 and the sleeve 19 can move along the outer wall of the support cylinder 20 under the action of a cylinder. An upper cylinder 15 is provided above the lower cylinder 18. A number of guide rods are provided in the upper cylinder 15. The guide rods pass through the lower cylinder 18 and are connected to the top of the support cylinder 20. The top of the support cylinder 20 is equipped with a pneumatic indicator. For valve 17, the inner wall of the sleeve 19 is recessed to form three installation grooves one, the wall surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com