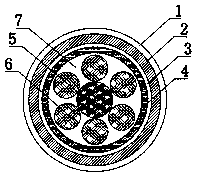

Anti-ultraviolet photovoltaic cable and stranding equipment thereof

A technology of anti-ultraviolet and photovoltaic cables, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of cable irregularity, cable shape deformation, and tensile strength reduction, so as to save filling materials, increase flexibility, Effect of improving stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

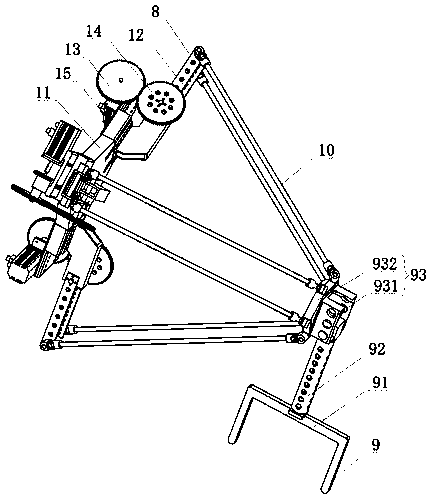

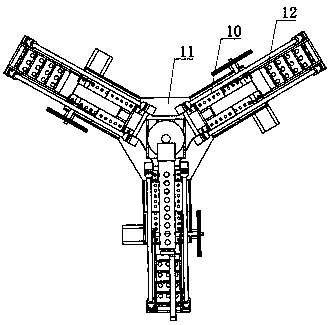

[0032] An anti-ultraviolet photovoltaic cable processing and stranding equipment, including a wire drawing mechanism, the wire drawing mechanism includes a tension assembly 8, a tension bracket 9, three symmetrically distributed tension rods 10, the left end of the tension rod 10 is connected to the tension assembly 8, and The right end of the tension rod 10 is connected to the tension bracket 9, and the tension assembly 8 includes a tension plate 11, three symmetrically distributed tension arms 12, a driving wheel 13, a driven wheel 14, and a driving motor 15 for driving the driving wheel 13 to move. The tension arm 12 is evenly distributed on the surface of the tension disc 11, the tension arm 12 is provided with a driven wheel 14, and the tension disc 11 is provided with a driving wheel 13 for driving the driven wheel 14 to move; The pull bracket 9 is provided with twisted through holes.

[0033] The tension rod 10 adopts a telescopic rod, and the tension arm 12 is provided...

Embodiment 2

[0037] An anti-ultraviolet photovoltaic cable processing and stranding equipment, including a wire drawing mechanism, the wire drawing mechanism includes a tension assembly 8, a tension bracket 9, three symmetrically distributed tension rods 10, the left end of the tension rod 10 is connected to the tension assembly 8, and The right end of the tension rod 10 is connected to the tension bracket 9, and the tension assembly 8 includes a tension plate 11, three symmetrically distributed tension arms 12, a driving wheel 13, a driven wheel 14, and a drive motor 15 for driving the driving wheel 13. The tension arm 12 is evenly distributed on the surface of the tension disc 11, the tension arm 12 is provided with a driven wheel 14, and the tension disc 11 is provided with a driving wheel 13 for driving the driven wheel 14 to move; The pull bracket 9 is provided with twisted through holes.

[0038] The tension rod 10 adopts a telescopic rod, and the tension arm 12 is provided with 6 ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap