Needle head part opposite blade grinding device for sterile needle knives

A needle head and grinding technology, which is applied in the direction of grinding workpiece supports, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem of slow production speed, low processing efficiency, and the needle head of sterile needle knife is not polished enough. problems, to achieve the effect of improving processing efficiency, ingenious design, and ensuring grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

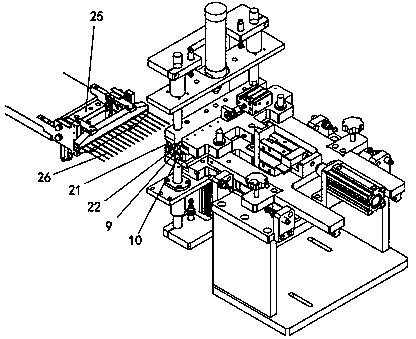

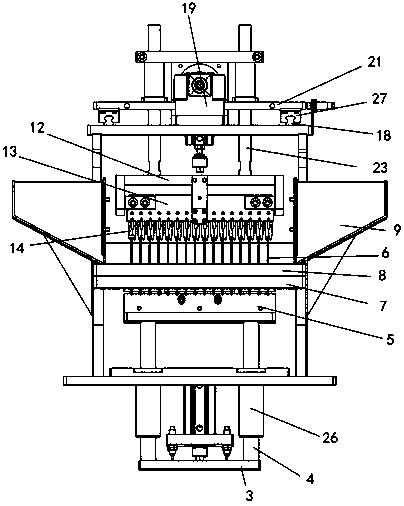

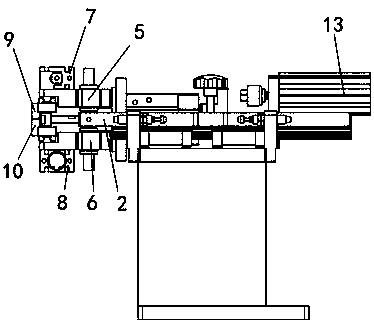

[0024] Such as Figures 1 to 10 As shown, the needle head-to-blade grinding device of the sterile needle knife proposed by the present invention is arranged on one side of the rotary station of the rotary feeder holding the sterile needle knife, and includes a frame 1, a The walking bottom frame 2 on the frame 1, the two rows of left and right parallel linear slide rails 3 installed on the upper part of the frame 1, and the sliding rail seat arranged on the lower part of the walking bottom frame 2 and matched with the linear slide rails 3 4. The upper grinding installation plate 5 located on the upper side of the front end of the walking bottom frame 2, the lower grinding installation plate 6 installed on the lower side of the front end of the walking bottom frame 2, and the upper grinding installation plate 5 installed on the upper grinding installation plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com