Sound insulation wall coat layer and production method thereof

A production method and sound-insulating layer technology, applied in the field of sound-insulating wall cladding and its production, can solve problems such as sagging transmission loss, decreased transmission loss performance, and harmful sound-insulating ability of glass, etc., and achieve simple structure, excellent sound-insulating performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

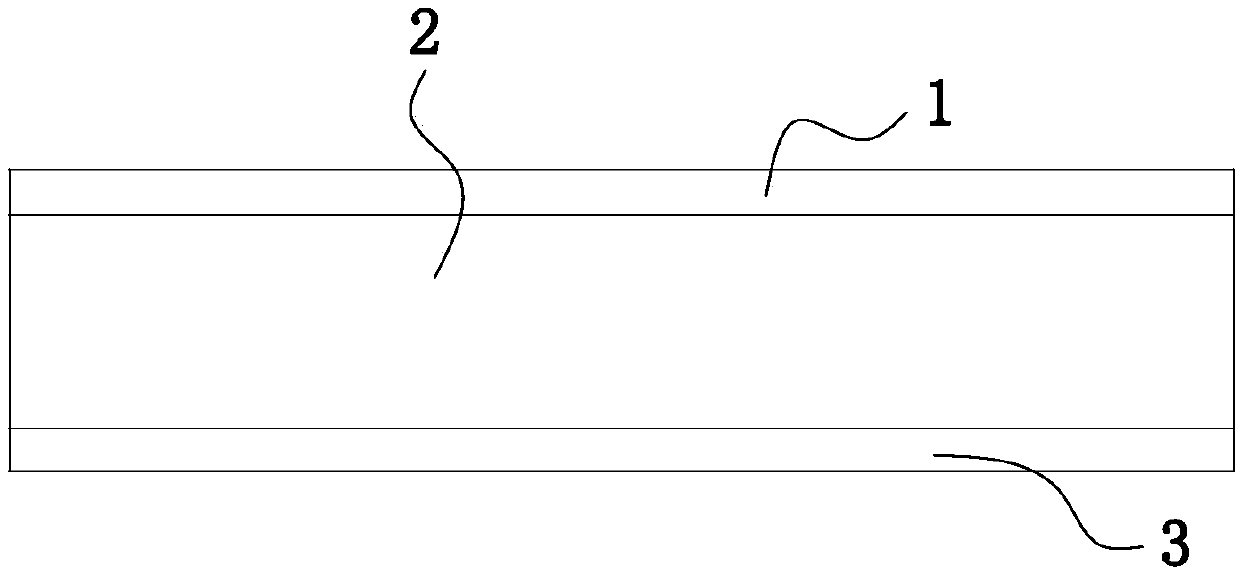

[0046] Such as figure 1 As shown, a soundproof wall sticker includes a decorative layer 1, a non-woven fabric layer 3, and a soundproof layer 2 for sound insulation. One side of the soundproof layer 2 and the decorative layer 1 are bonded by an adhesive layer B, and the soundproof layer 2 The other side of and the non-woven fabric layer 3 are bonded by the adhesive layer A.

[0047] The thickness of the sound insulation layer 2 is 0.01-5 mm, the thickness of the non-woven fabric layer 3 is 0.01-2 mm, and the sum of the thicknesses of the decorative layer 1, the sound insulation layer 2 and the non-woven fabric layer 3 is 0.2-10 mm.

[0048] The sound insulation layer 2 is made of high-damping rubber and is vulcanized rubber with a damping coefficient greater than or equal to 0.3, preferably the vulcanized rubber with a damping coefficient greater than or equal to 0.4. Rubber is a high-elastic polymer material. The damping of rubber is the internal frictional resistance of the movem...

Embodiment 2

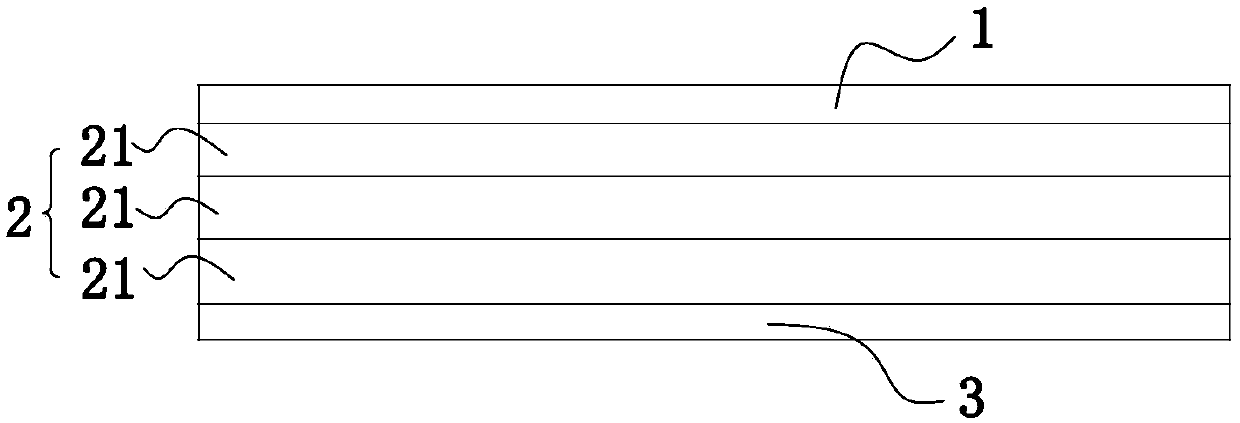

[0054] Such as figure 2 As shown, the sound insulation layer 2 includes a plurality of sound insulation sheets 21, and the plurality of sound insulation sheets 21 are laminated by pressing sheets. The plurality of sound insulation sheets 21 can be made of the same type of rubber, and the plurality of sound insulation sheets 21 can also be of different types. The multiple sound-insulating sheets 21 can be made of rubber with the same damping coefficient, and the multiple sound-insulating sheets 21 can also be made of rubber with different damping coefficients.

[0055] This embodiment is the same as the first embodiment except that the above-mentioned structure is different from the first embodiment.

Embodiment 3

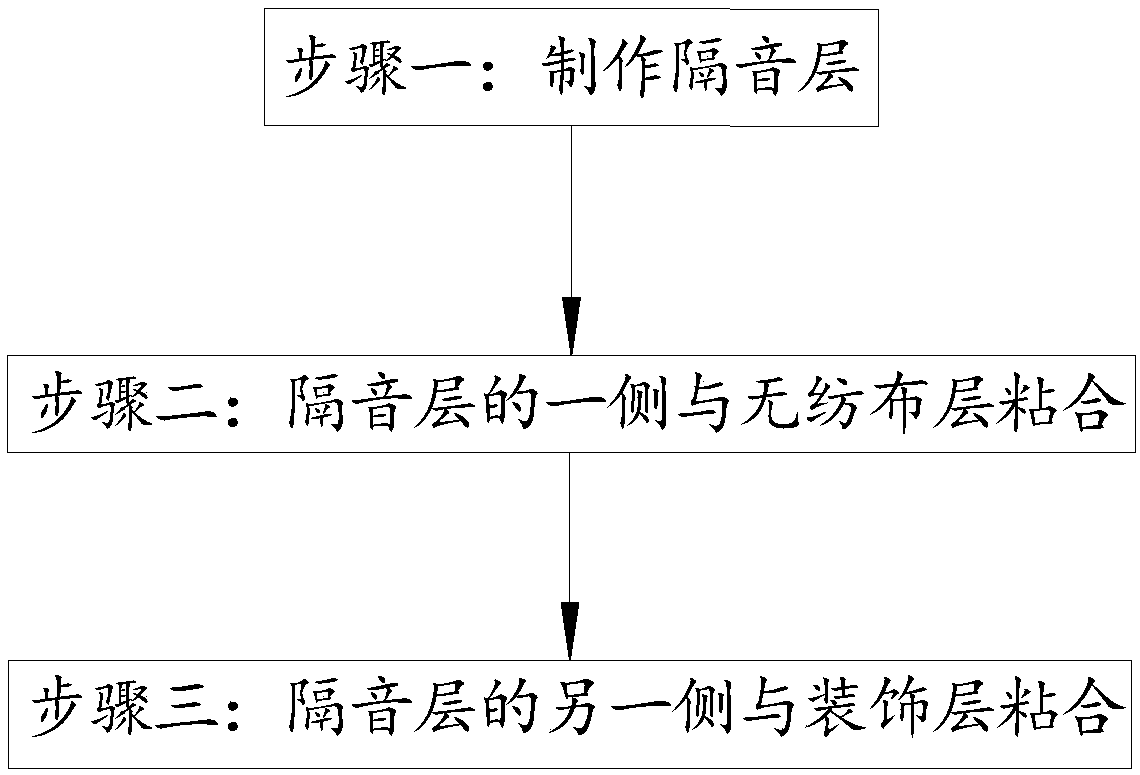

[0057] Such as figure 1 with 3 As shown, a method for producing a soundproof wall sticker includes the following steps:

[0058] Step one: calender the sound-insulating material into a sheet structure with a calendering equipment to form the sound-insulating layer 2.

[0059] The rolling thickness of the sound insulation layer 2 is made into a thickness of 0.01-5mm, and the thickness of the sound insulation layer 2 is 0.01-5mm, preferably a soundproof layer 2 with a thickness of 0.1-3mm, more preferably a soundproof layer with a thickness of 0.2-2mm 2.

[0060] Step two, bonding one side of the sound insulation layer 2 with the non-woven fabric layer 3;

[0061] Use non-woven materials to make a non-woven fabric layer 3 with a thickness of 0.01-2 mm, preferably a non-woven fabric layer 3 with a thickness of 0.01-1 mm, more preferably a non-woven fabric layer 3 with a thickness of 0.01-0.5 mm; The machine coats the adhesive uniformly on the surface of the non-woven fabric layer 3, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com