Efficient cooling forming fiber spinneret plate

A technology of cooling forming and spinneret, which is applied in the direction of spinneret assemblies, textiles and papermaking, etc., to achieve the effects of increasing outflow rate, improving cooling timeliness, and improving cooling uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

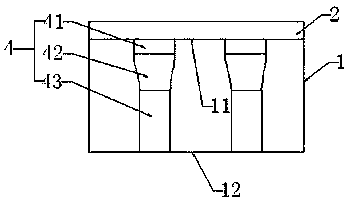

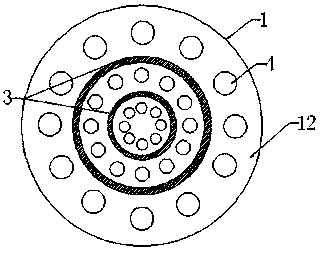

[0017] A high-efficiency cooling molding fiber spinneret, including a spinneret body 1, a filter screen 2 and a cooling system 3; wherein, the spinneret body 1 is a cylinder, and the filter screen 2 is embedded and fixed on the spinneret body 1, the filter screen is a detachable double-layer structure, and its outer aperture is twice that of the inner aperture. When a certain amount of impurities are intercepted on the outer side of the filter screen, the outer filter screen can be disassembled and cleaned directly. , which can reduce the cleaning frequency of the inner filter, reduce the cleaning difficulty of the filter as a whole, and improve the filtering quality.

[0018] The spinneret body 1 is provided with spinneret holes 4 arranged at regular intervals, which are distributed in a ring around the center of the spinneret body 1 , and the distance between the spinneret holes between adjacent rings is 3-10 mm. The spinneret hole 4 runs through the spinneret body 1, and it...

Embodiment 2

[0022] The difference from Example 1 is that the length ratio of the feed section 41 , the middle section 42 and the discharge section 43 on the spinneret body 1 is 1.5:3:5.

[0023] The diameter of the outer aperture is three times that of the inner aperture.

[0024] The diameter of the spinneret hole 4 is set as follows: the diameters of the spinneret holes on the same ring are the same, and the diameters of the spinneret holes on each ring from the center of the spinneret body 1 to the edge increase in an arithmetic sequence, And the tolerance is 3 μm, and the minimum diameter of the spinneret hole near the center is 3 μm.

[0025] The design of the spinneret hole of the present invention, on the one hand, improves the shaping effect of the fiber filament and increases its tensile strength; on the other hand, it effectively improves the outflow efficiency of the fiber mucus, avoids mucus retention, and improves the outflow rate; the design of the cooling system The coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com