Water injection booster pump oil lubrication sealing circulating device

A technology of circulating device and booster pump oil, which is applied to the components of pumping device for elastic fluid, pump components, variable displacement pump components, etc. It can solve the problem of frequent replacement, eliminate major safety hazards, and reduce the friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

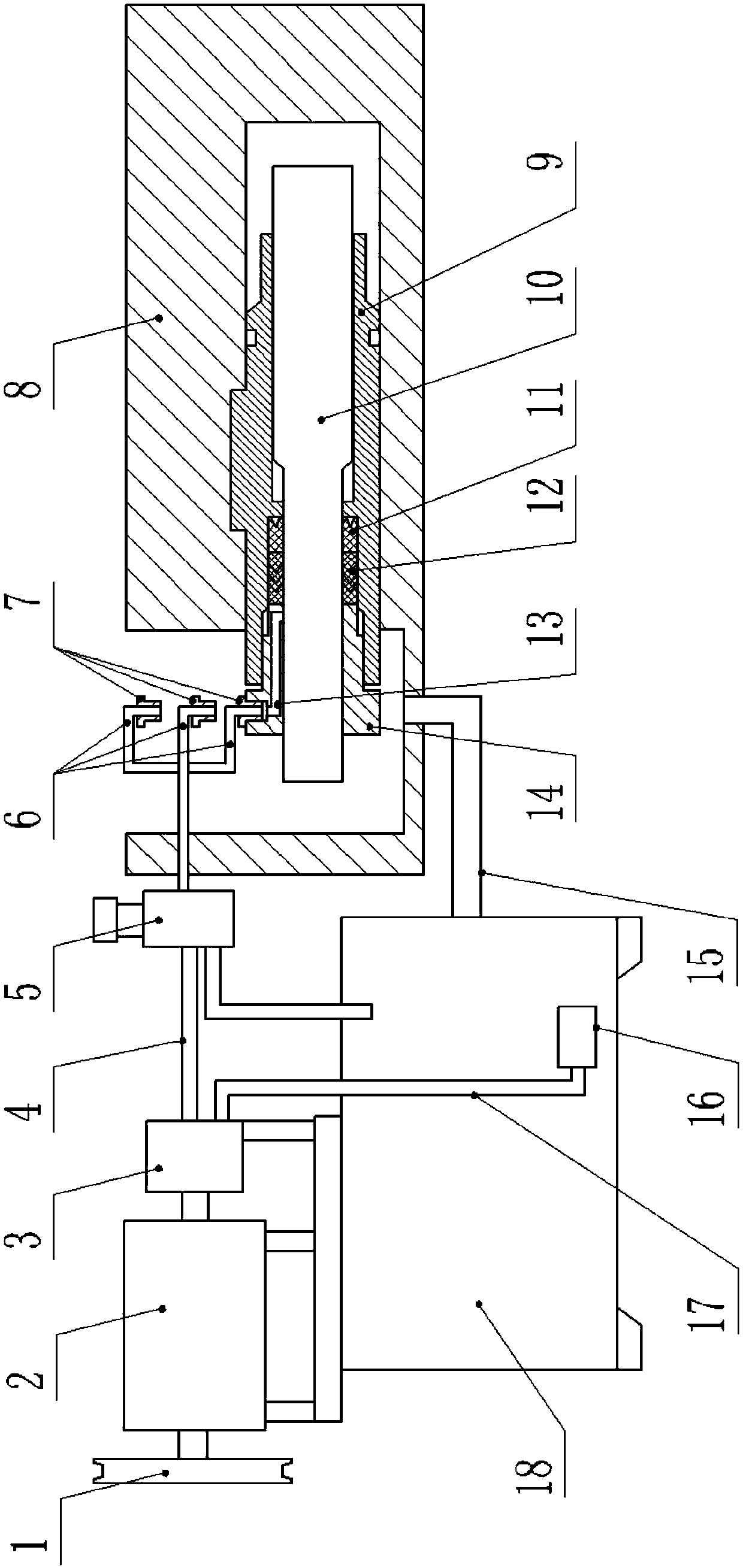

[0023] Such as figure 1 As shown, the water injection booster pump oil lubrication and sealing circulation device includes a pump body 8, a plunger 10 is arranged inside the pump body 8, and an auxiliary body 9 is arranged between the plunger 10 and the pump body 8, A sealing component is provided between the plunger 10 and the auxiliary body 9 . One end of the auxiliary body 9 is provided with a pressure cap 14 , the pressure cap 14 is located between the auxiliary body 9 and the plunger 10 and the pressure cap 14 abuts against the sealing member. The auxiliary body 9 is provided with an annular limiting boss extending toward the plunger 10, and the pressure cap 14 tightens the sealing part on the limiting boss, and the sealing part ensures the sealing during the reciprocating movement of the plunger 10. The leakage of sewage is avoided, and the labor intensity of workers is effectively reduced. The sealing part includes one or both of the V-shaped sealing ring 12 and the Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com