Hydraulic suspension type anti-leakage submersible pump

A suspension and anti-leakage technology, applied in the direction of non-variable pumps, pumps, pump devices, etc., can solve the problems of affecting the service life of the motor, large energy consumption in structural design, and poor water output, so as to improve the service life and structure The design is reasonable and reliable, and the effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

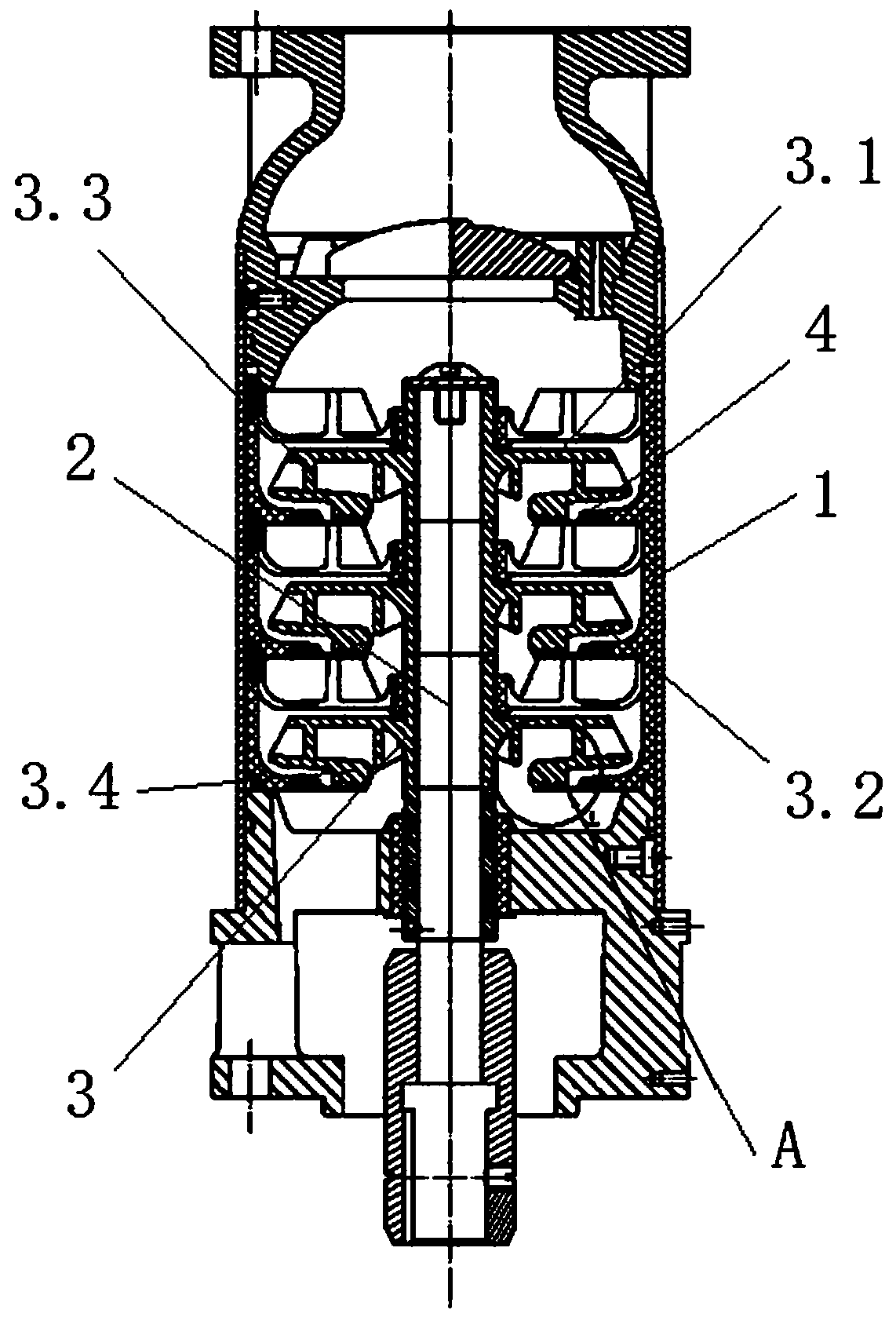

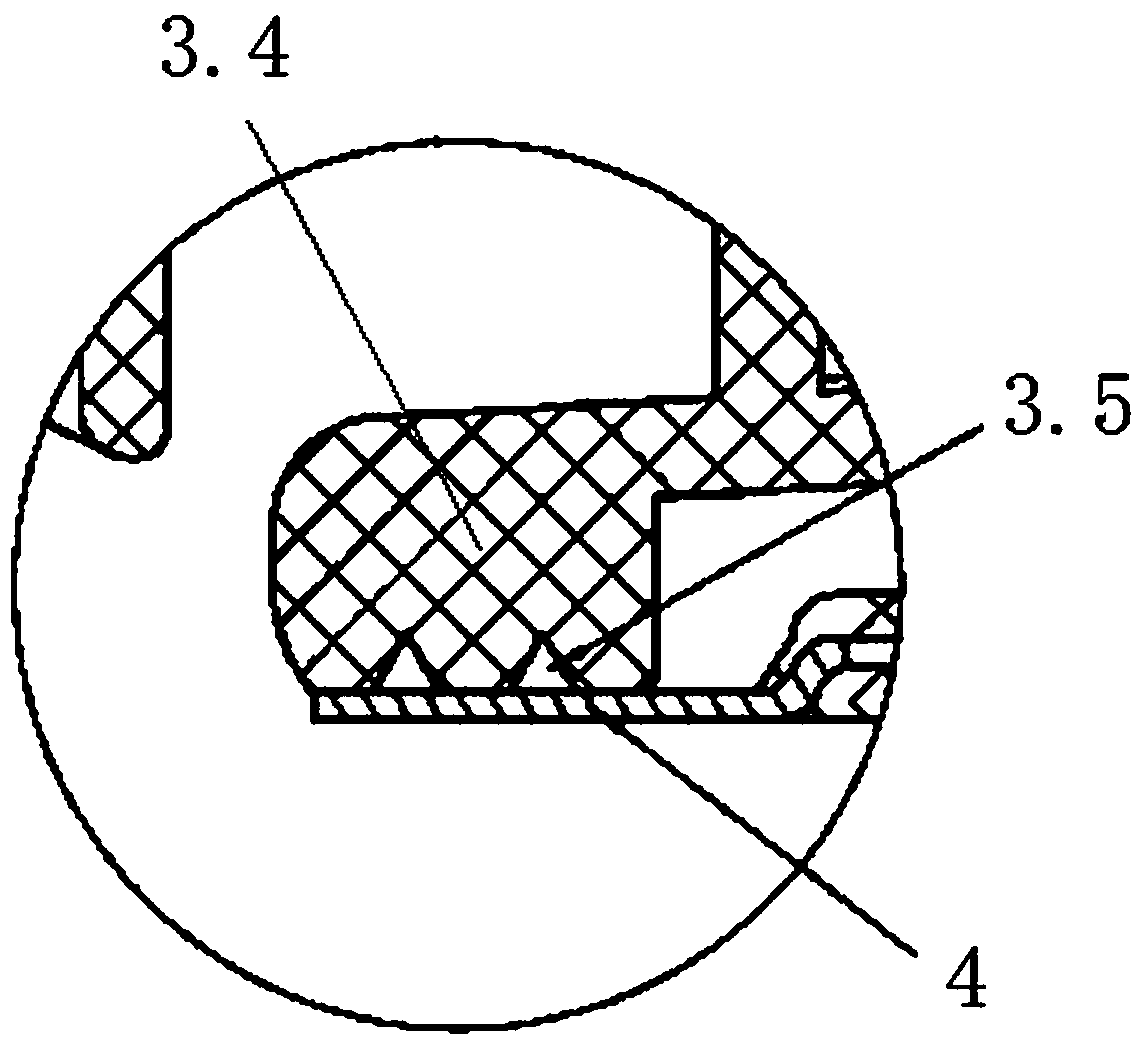

[0012] The hydraulic suspension type anti-leakage submersible pump includes a cylindrical pump casing 1, a pump shaft 2 with a polygonal horizontal section is arranged at the axis of the cylindrical pump casing 1, and a number of suspended impellers 3 distributed up and down are sleeved on the pump shaft 2. The suspended impeller 3 is made by connecting the upper cover plate 3.1 and the lower cover plate 3.2 through the blade 3.3, and the outer diameter of the upper cover plate 3.1 is smaller than the outer diameter of the lower cover plate 3.2, and the lower end surface of the lower cover plate 3.2 is provided with a And the centerline is an involute suspension block 3.4, the lower end surface of the suspension block 3.4 is provided with a suspension groove 3.5, and the inner wall of the cylindrical pump casing 1 is provided with a stainless steel sealing plate 4 supporting each suspension block 3.4.

[0013] The outer wall of the cylindrical pump casing 1 is provided with sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com