All view field statistics expression method of alloy microstructure via fluid micro-detection strain

A technology of microstructure and full field of view, which is applied in the field of surface micro-area analysis in the field of material science, can solve the problems of inaccurate quantitative determination, etc., and achieve the effects of easy standardization, avoiding interference factors, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] (Example for the characterization of carbide and ferrite micromechanical properties in high-chromium cast iron of brand KmTBCr15Mo)

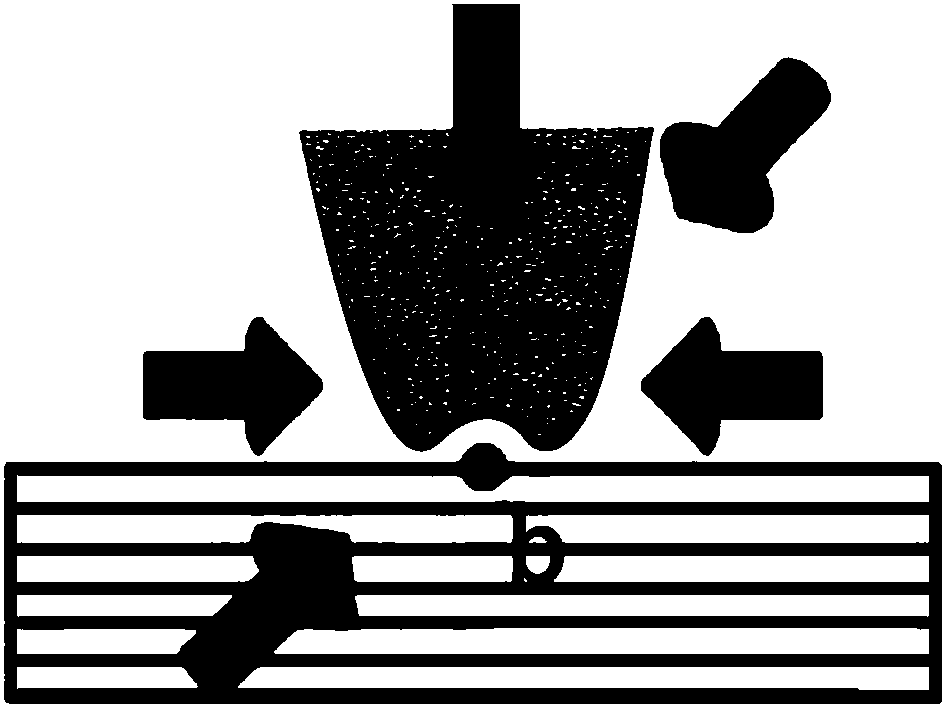

[0055] In this embodiment, the full-field metallographic characterization of the carbide and ferrite microstructure in the brand KmTBCr15Mo high-chromium cast iron by isostatic pressing technology is taken as an example to illustrate.

[0056] Characterization of Micromechanical Properties of Carbide and Ferrite

[0057] a) The high-chromium cast iron sample of grade KmTBCr15Mo is prepared according to the requirements of metallographic analysis; the prepared sample is ground and polished to make the surface of the sample reach a mirror finish without grinding defects, and a square area is marked on the surface of the polished sample , the size of the marked area is 10mm×10mm.

[0058] b) Use a white light interference three-dimensional topography instrument to measure the initial topography of the alloy sample surface, and obtain the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com