Protection cover used for insulating sleeve repairing, insulation sleeve and repairing method

A technology for insulating bushings and protective sleeves, applied in the field of protective sleeves, can solve problems such as hidden dangers in the operation of high-voltage equipment and breakdown of insulating bushings, and achieve the effects of avoiding breakdown phenomena, avoiding corrosion, and blocking possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

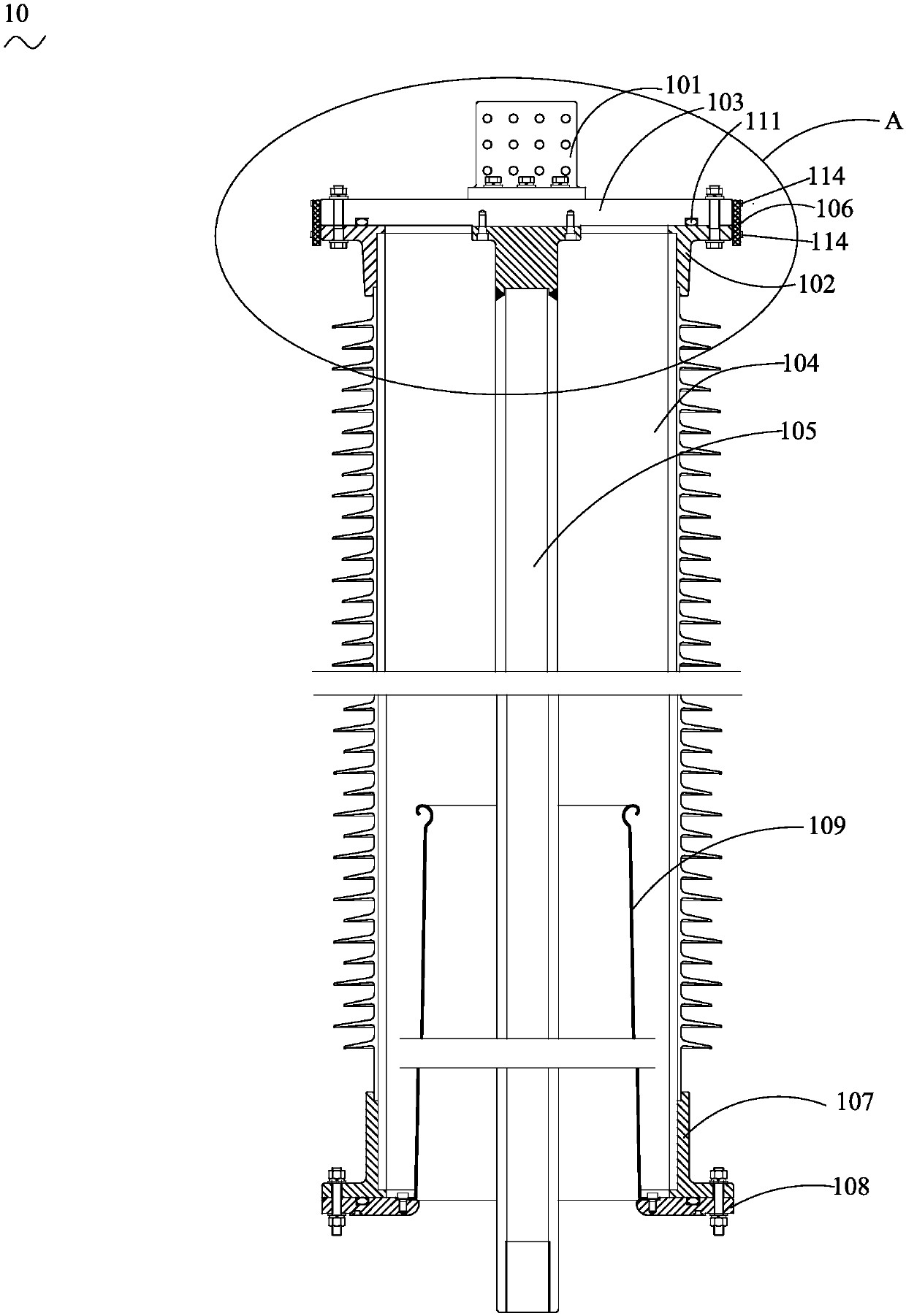

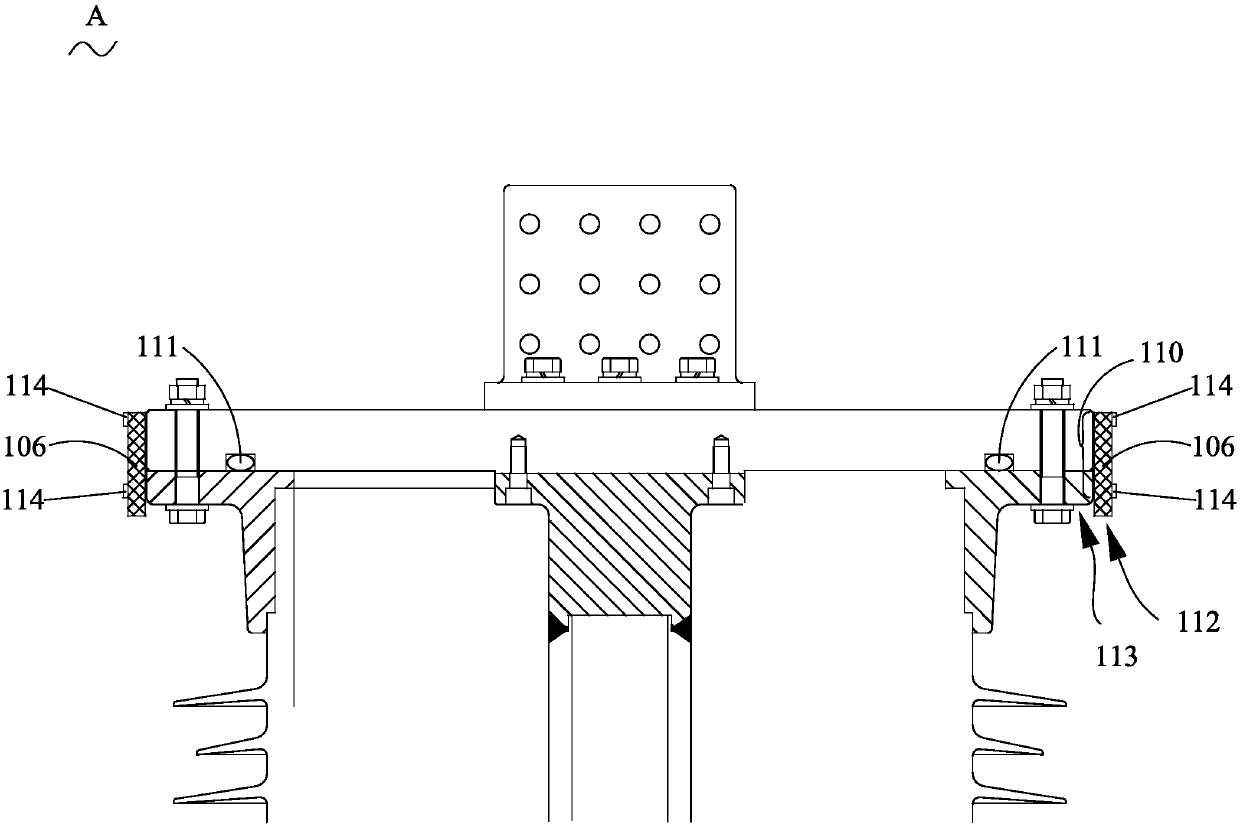

[0060] Please refer to Figure 1-Figure 5 , the first embodiment of the insulating sleeve of the present invention, such as figure 1 As shown, the insulating bushing 10 includes:

[0061] Terminal 101, upper flange 102, upper sealing plate 103, insulating tube 104, conductive rod 105, lower flange 107, lower sealing plate 108 and shielding electrode 109;

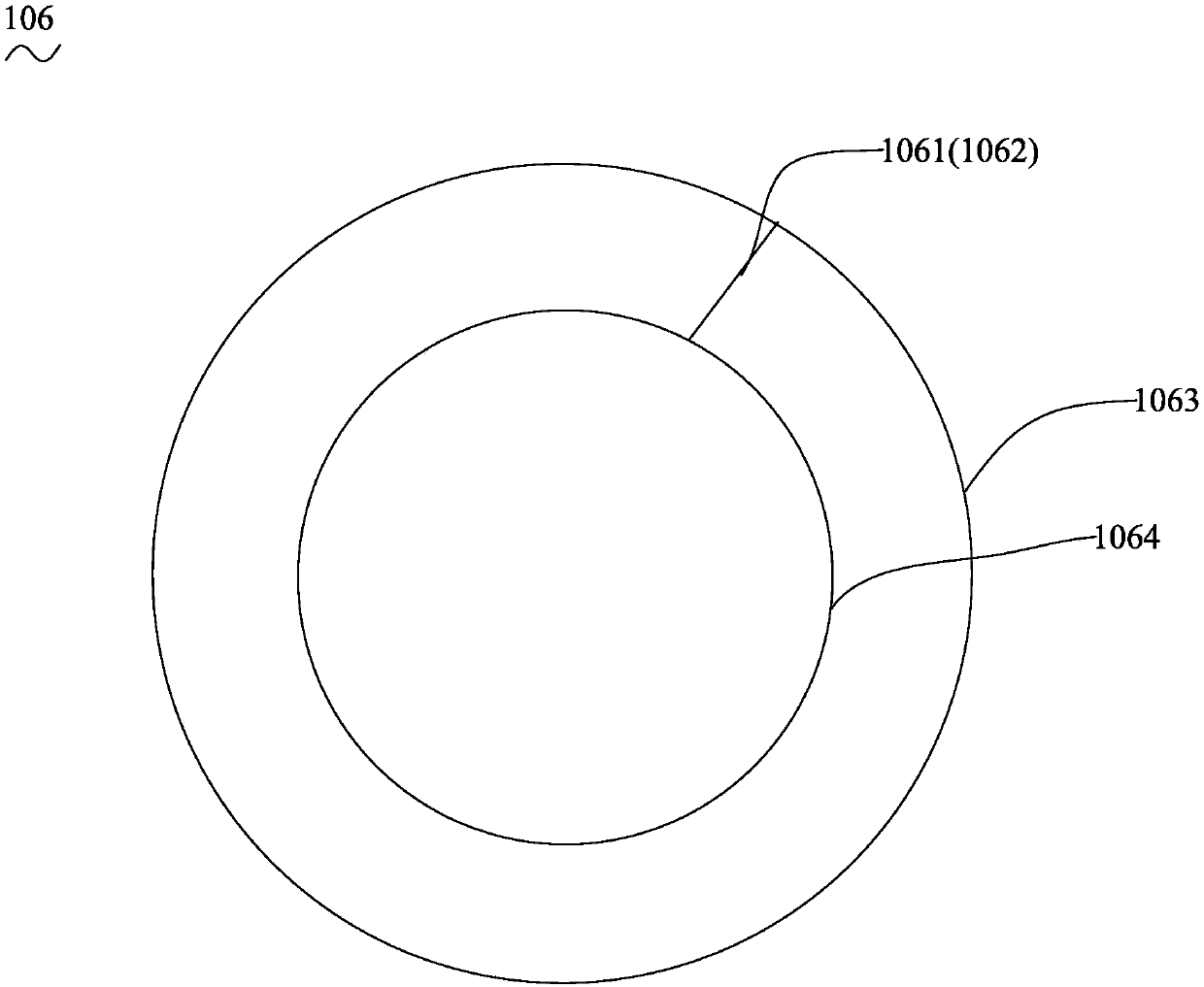

[0062] The conductive rod 105 is coaxially installed inside the insulating tube 104 and passes through the shielding electrode 109. One end of the conductive rod 105 is connected and fixed to the upper sealing plate 103, and the upper sealing plate 103 is fixed to one end of the insulating tube 104 through the connection with the upper flange 102. The lower sealing plate 108 is equipped with a shielding electrode 109, and the lower sealing plate 108 is fixed on the other end of the insulating tube 104 through the connection with the lower flange 107, and the outer peripheral surface 110 connected between the upper flange 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com