Crude aldehyde extraction equipment

An extraction equipment and a technology for aldehydes, applied in the field of aldehyde extraction equipment, can solve the problems of unstable product quality, long rectification time, large product loss, etc., and achieve the effects of avoiding side effects, improving yield, and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

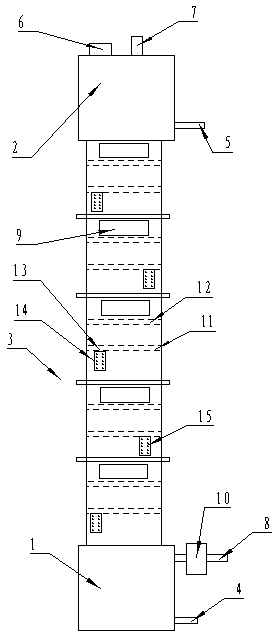

[0007] like figure 1 Shown, a kind of gross aldehyde extracting equipment, it comprises bottom reaction tank 1, top reaction tank 2, tank body 3, high-pressure water inlet pipe 4, water outlet pipe 5, feed port 6, air pressure balance port 7, discharge port 8, Stirrer 9, discharge quantitative controller 10, first filter screen 12 and second filter screen 11, the lower reaction tank 1 and the upper reaction tank 2 are connected through the tank body 3, wherein the high-pressure water inlet pipe 4 and the discharge port 8 are set On the wall of the lower reaction tank 1, and communicated with the lower reaction tank 1, wherein the water outlet pipe 5, the feed port 6 and the air pressure balance port 7 are arranged on the upper reaction tank 2, and communicated with the upper reaction tank 2, the outlet The material quantitative controller 10 is rotatably arranged inside the discharge port 8, and the tank body 3 is connected together by several cylindrical bodies connected in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com