Wettable powder mixer

A wettable powder and mixer technology, which is used in mixers, mixers with rotary stirring devices, mixer accessories, etc., can solve the problem that materials are easily adsorbed on the tank wall of the mixing tank and affect the particle size distribution of wettable powder particles. , prone to precipitation, suspension, stratification and other problems, to achieve the effect of reducing heat generation, rapid and effective mixing, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

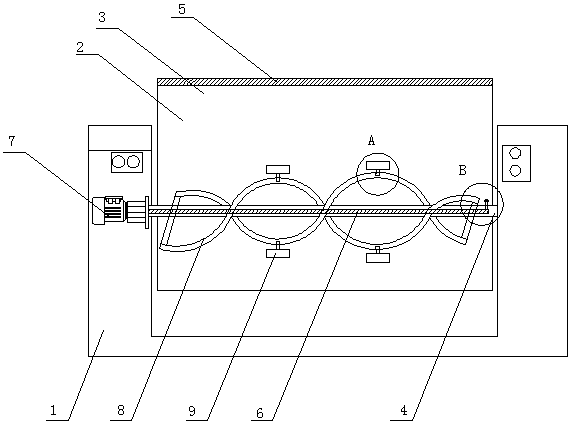

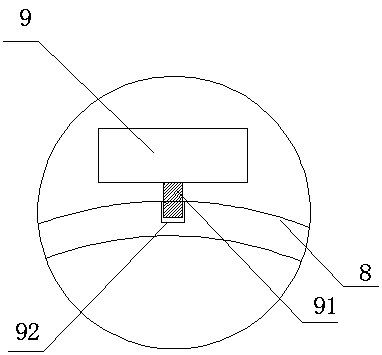

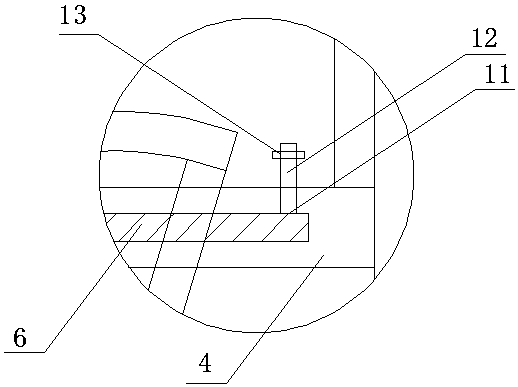

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 A wettable powder mixer shown includes a mixer base 1 and a U-shaped mixing tank 2 arranged on the base. The mixing tank includes a feed inlet 3 arranged on the top and an agitating shaft 4 arranged inside. The mixing tank is stirred by The shaft is connected to the base, and the feed port is provided with a sealing cover 5, which can be sealed on the feed port; the stirring shaft is provided with a hollow tube 6, and the stirring shaft is sleeved on the outside of the hollow tube, and the cooling liquid is provided in the hollow tube The stirring shaft is connected to the motor 7, the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com