Fluidized bed

A fluidized bed, cyclone separator technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of large back-mixing, secondary reaction of the target product, large bubbles, etc., and achieve simple structure and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

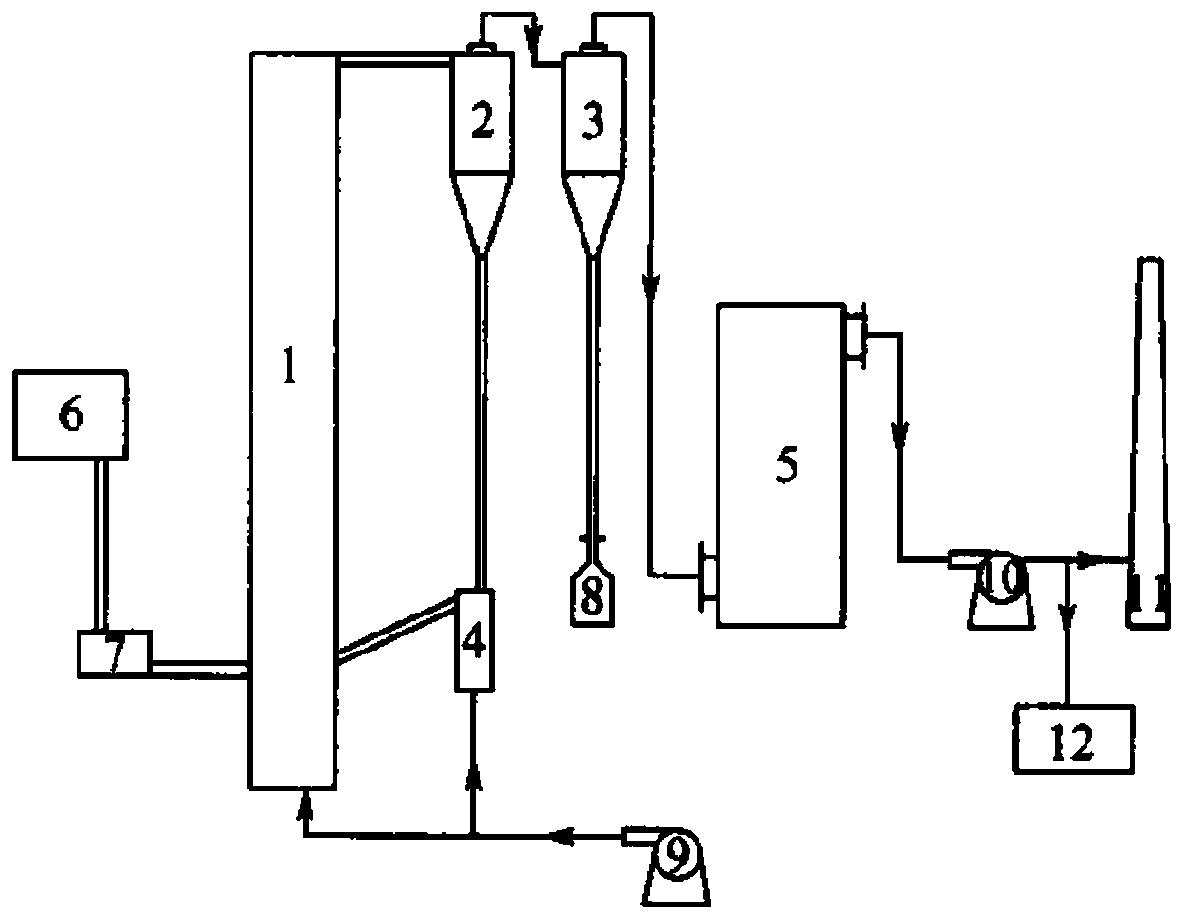

[0015] A fluidized bed, consisting of a device body and an auxiliary system; the device body includes a furnace body 1, a cyclone separator, a feeder 4 and an ash hopper 8; the cyclone separator is divided into two stages, and the furnace body 1 is connected in sequence The primary cyclone separator 2 and the secondary cyclone separator 3, the bottom end of the primary cyclone separator 2 is connected to the furnace body 1 through the feeder 4; the bottom end of the secondary cyclone separator 3 is connected to the ash hopper 8; Wind system, feeding system, and pressure and temperature measurement system; air supply system and feeding system are connected to furnace body 1; the other end of secondary cyclone separator 3 is connected to water cooler 5, induced draft fan 10 and chimney 11 in sequence. A pressure and temperature measurement system is provided between the induced draft fan 10 and the chimney 11, and the present invention adopts a flue gas analyzer 12. The air supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com