Autoclaved concrete block separator

A technology of autoclaved concrete and separator, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve problems such as personal safety accidents, slips and falls, and corners of autoclaved concrete blocks are damaged, and achieve safe and enhanced operation methods. The effect of hardness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

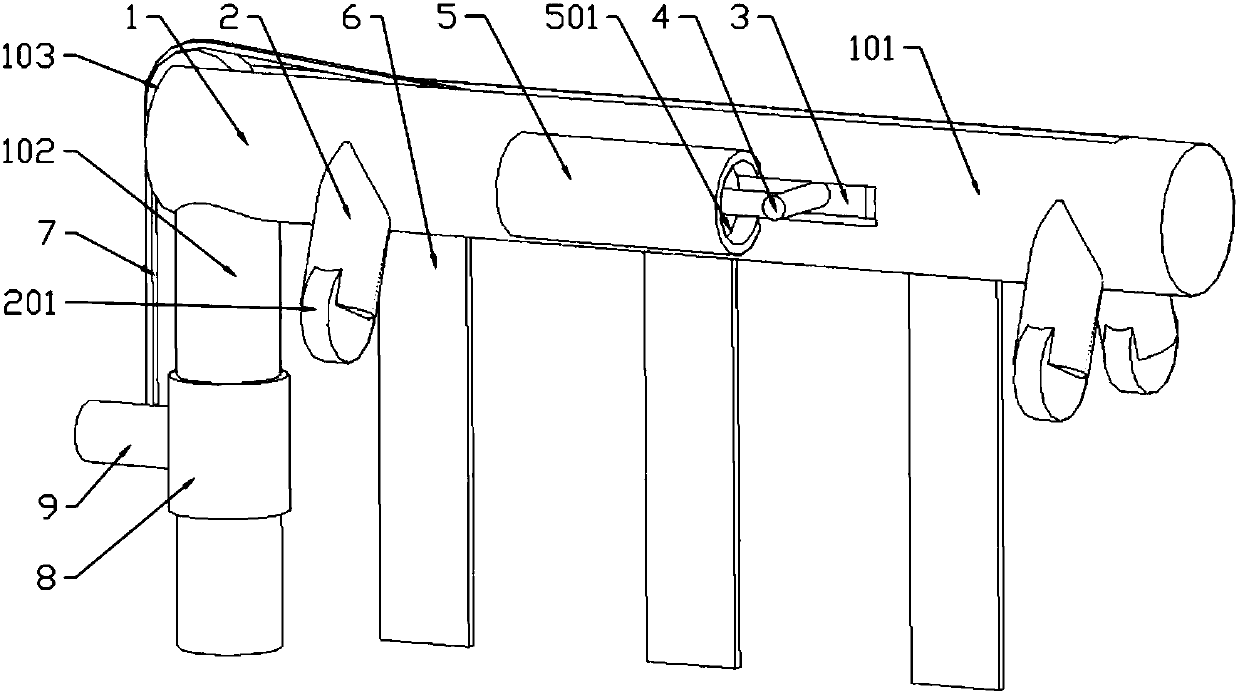

[0016] The reference signs in the accompanying drawings include: frame 1, lateral end 101, vertical end 102, pulley 103, support rod 2, roller 201, pull rod 3, connecting rod 4, pump 5, piston 501, air bag 6, Nylon rope 7, sleeve 8, push rod 9.

[0017] The embodiment of the autoclaved concrete block separator is basically as attached figure 1 As shown: it includes an L-shaped frame 1, a separation mechanism and a support portion. The frame 1 includes a horizontal end 101 and a vertical end 102. The support portion is located on the side of the horizontal end 101 facing the vertical end 102. It includes four support rods 2 of equal length and four rollers 201. One end of the support rod 2 is fixed on the lateral end 101, and the roller 201 is rotatably connected to the end of the support rod 2 away from the lateral end 101. The axis of the roller 201 is aligned with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com