Preparation method of cookware surface temperature change indicating coating

A cooking utensils and temperature-changing technology, applied in the field of temperature-changing coatings, can solve the problems of losing discoloration, inability to completely avoid discoloration coatings, and unsuitable cooking utensils, etc., to improve roughness and surface tension, and avoid rapid decline in non-stick properties , to avoid the effect of food nutrition loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment relates to a method for preparing a temperature change indicating coating on the surface of cookware, which includes the following steps:

[0036] 1. After sandblasting the surface of the cooker until the roughness Ra is 2-5 μm, preheat it to 40-70°C, spray the primer and topcoat of the ceramic coating in sequence, and cure it at 200-280°C to obtain a thickness of 25-45μm ceramic coating;

[0037] Two, add heat-sensitive color-changing pigment in the color paste component of commercially available ceramic paint, control the add-on of heat-sensitive color-changing pigment to be 2~5% of color paste component weight, add zirconium beads in the dispersing grinder, in Grinding at a speed of 1000-2000rpm, until the fineness does not exceed 20μm, the material is discharged, and after mixing and aging, a heat-sensitive color-changing ceramic coating is obtained;

[0038] 3. After the ceramic coating at the handle of the cooker is laser-polished into a regular p...

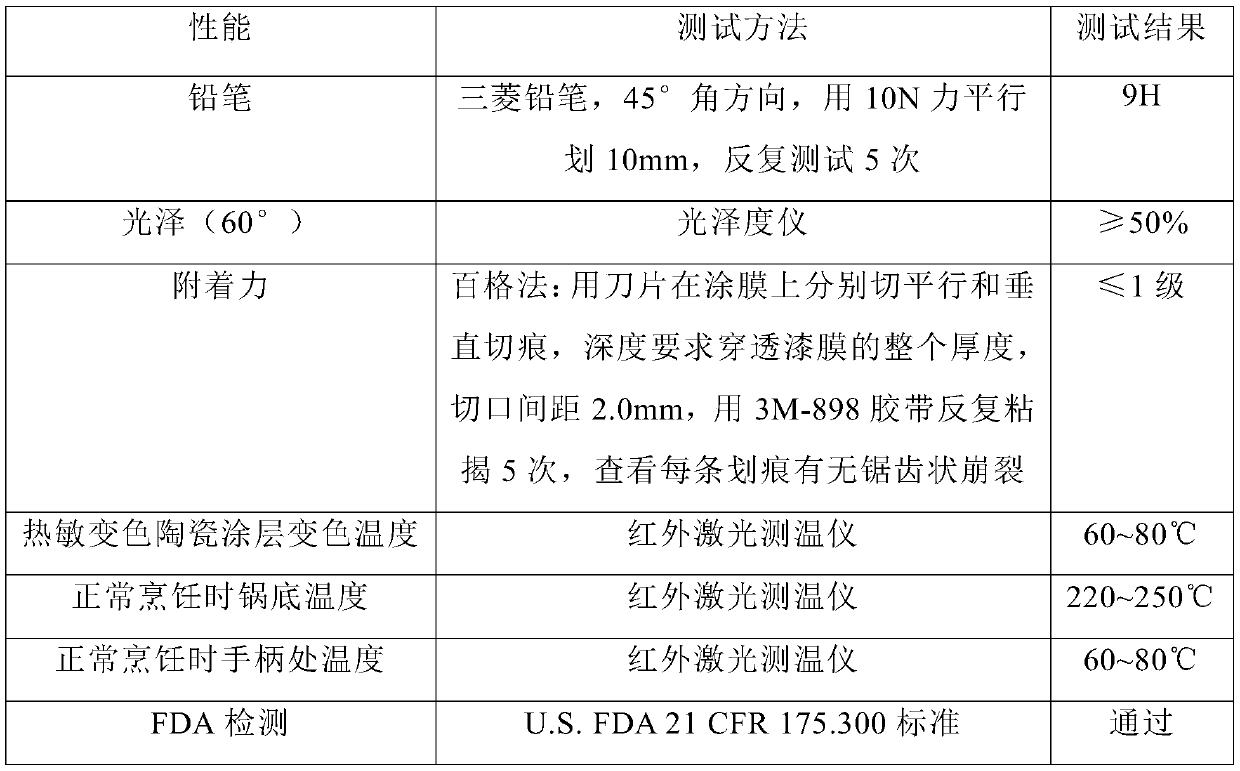

PUM

| Property | Measurement | Unit |

|---|---|---|

| discoloration temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com