Rolled steel bar drawing mechanism

A steel bar and rolling technology, which is applied in the field of metal heat treatment equipment, can solve problems such as inconvenient, laborious pulling, complex microstructure, etc., and achieve the effect of convenient and fast positioning and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

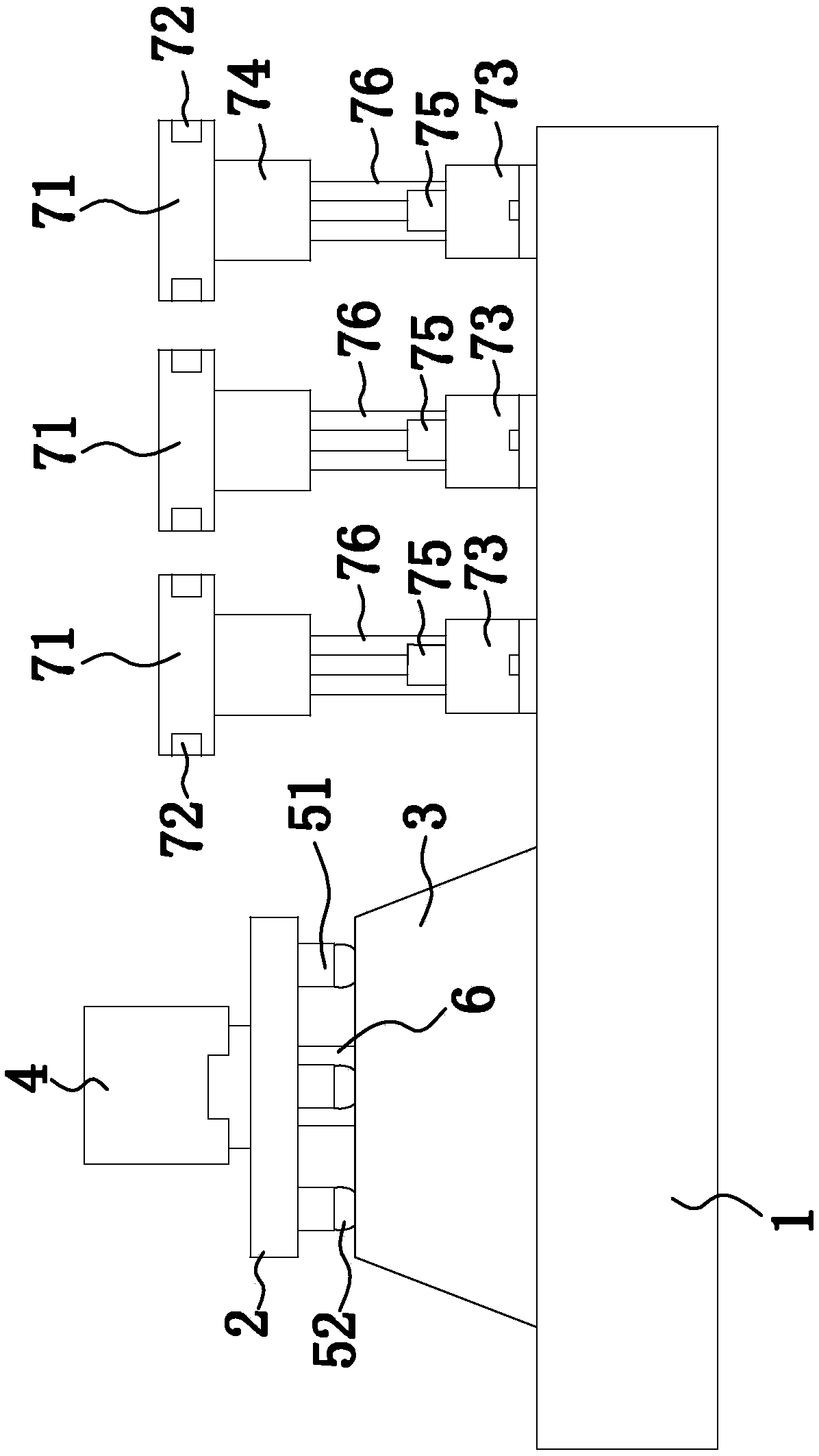

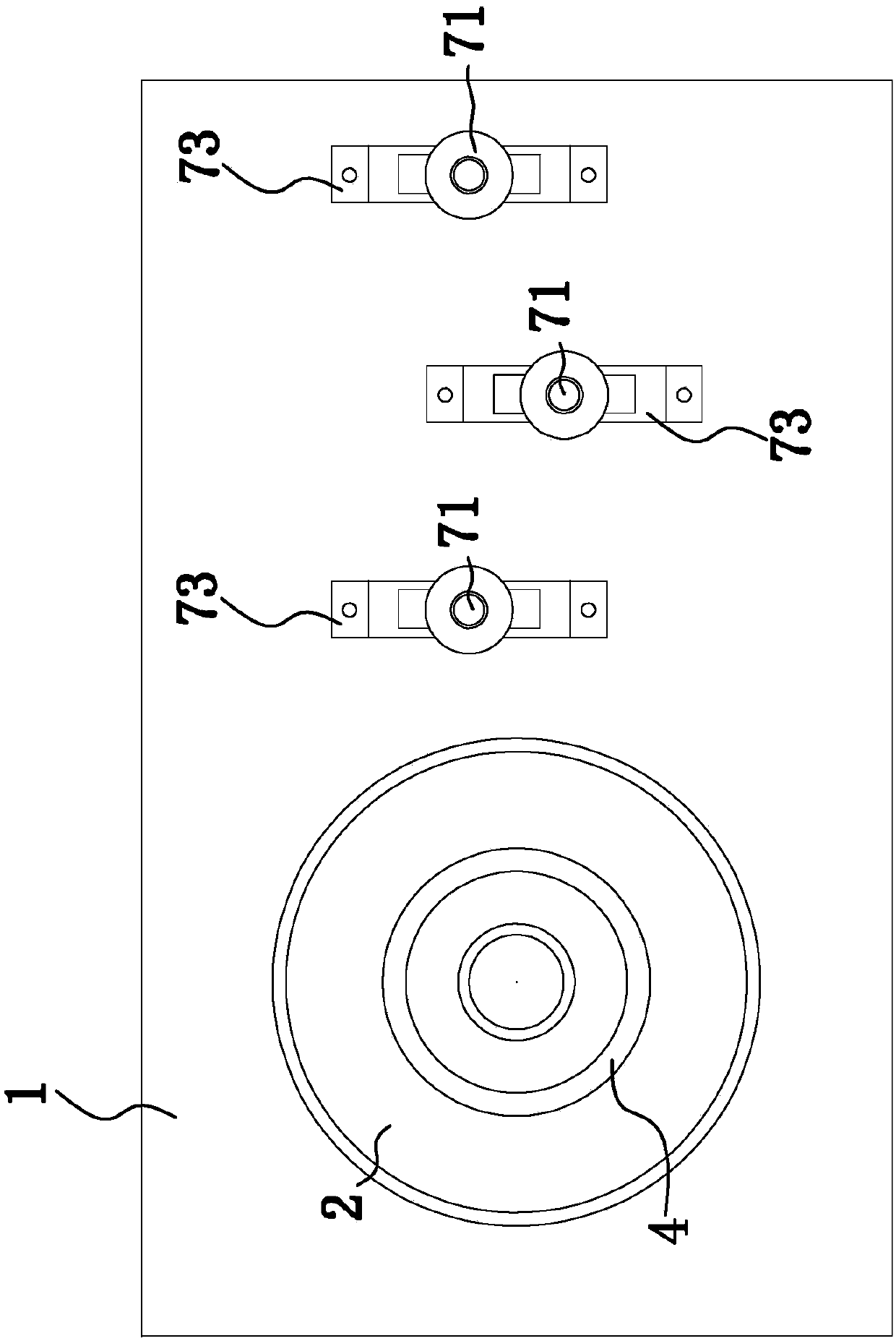

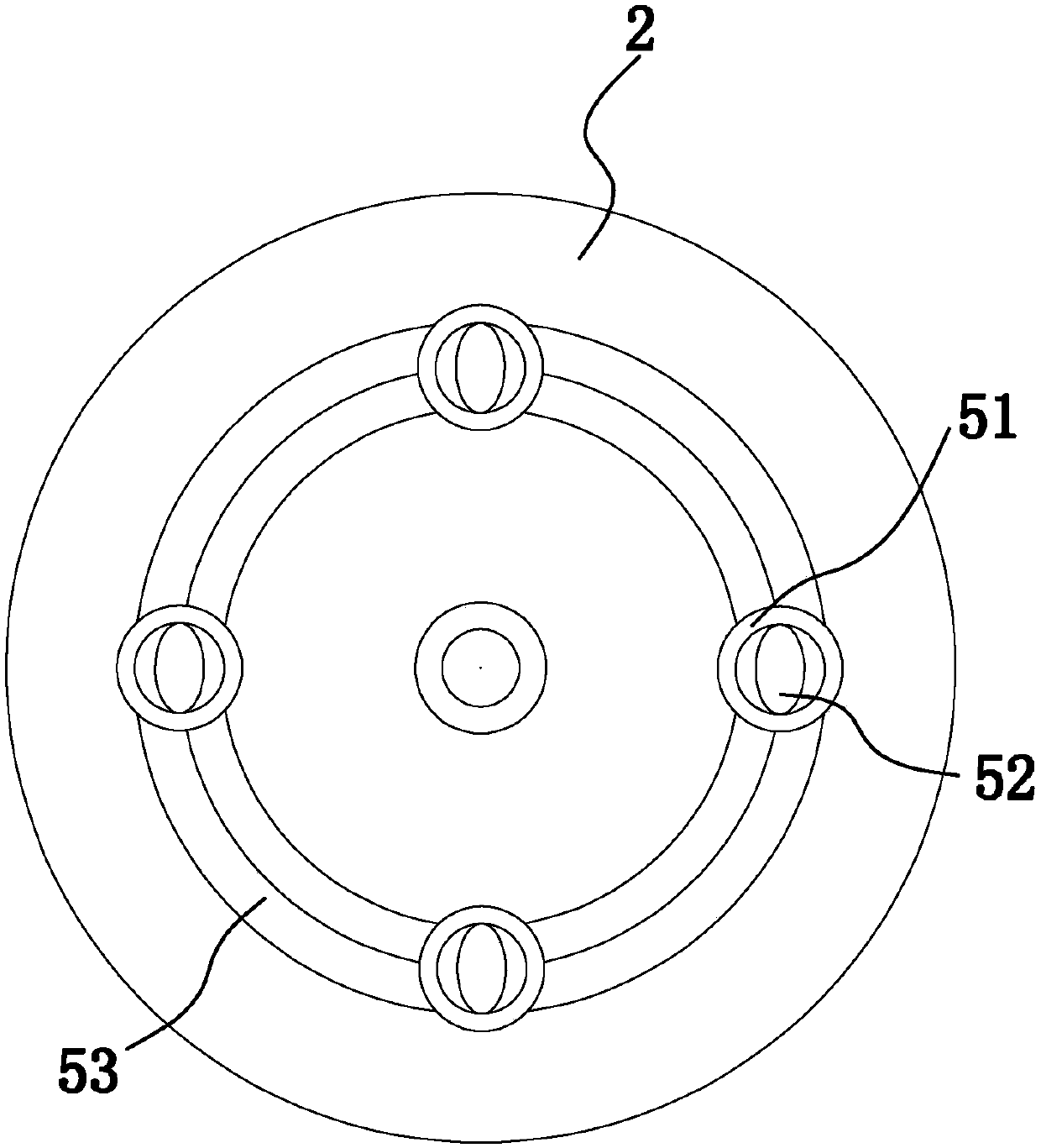

[0022] Such as Figures 1 to 5 As shown, the pulling mechanism of the coiled steel bar includes a steel rectangular bearing base 1, and the rectangular bearing base 1 is provided with a steel ring for the steel rolling assembly on the steel rotating table 2 to roll. The runway 3, the central part of the turntable 2 is provided with a steel central positioning pipe fitting 4 for the rolling steel bar bearing frame to be sleeved, and the side of the turntable 2 is provided with a rectangular bearing base 1 which is convenient to be placed on the turntable. The steel drawing structure for pulling the rolled steel bars on the 2, the setting of the steel circular runway 3, the rotating table 2, the rolling assembly and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com