Method for improving ground embossing efficiency of constructor

A technology for construction workers and embossing, which is applied in the field of construction, can solve the problems of increasing embossing time, increasing labor intensity, and inconvenience, and achieves the effects of avoiding strain, improving embossing efficiency, and protecting wrists

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

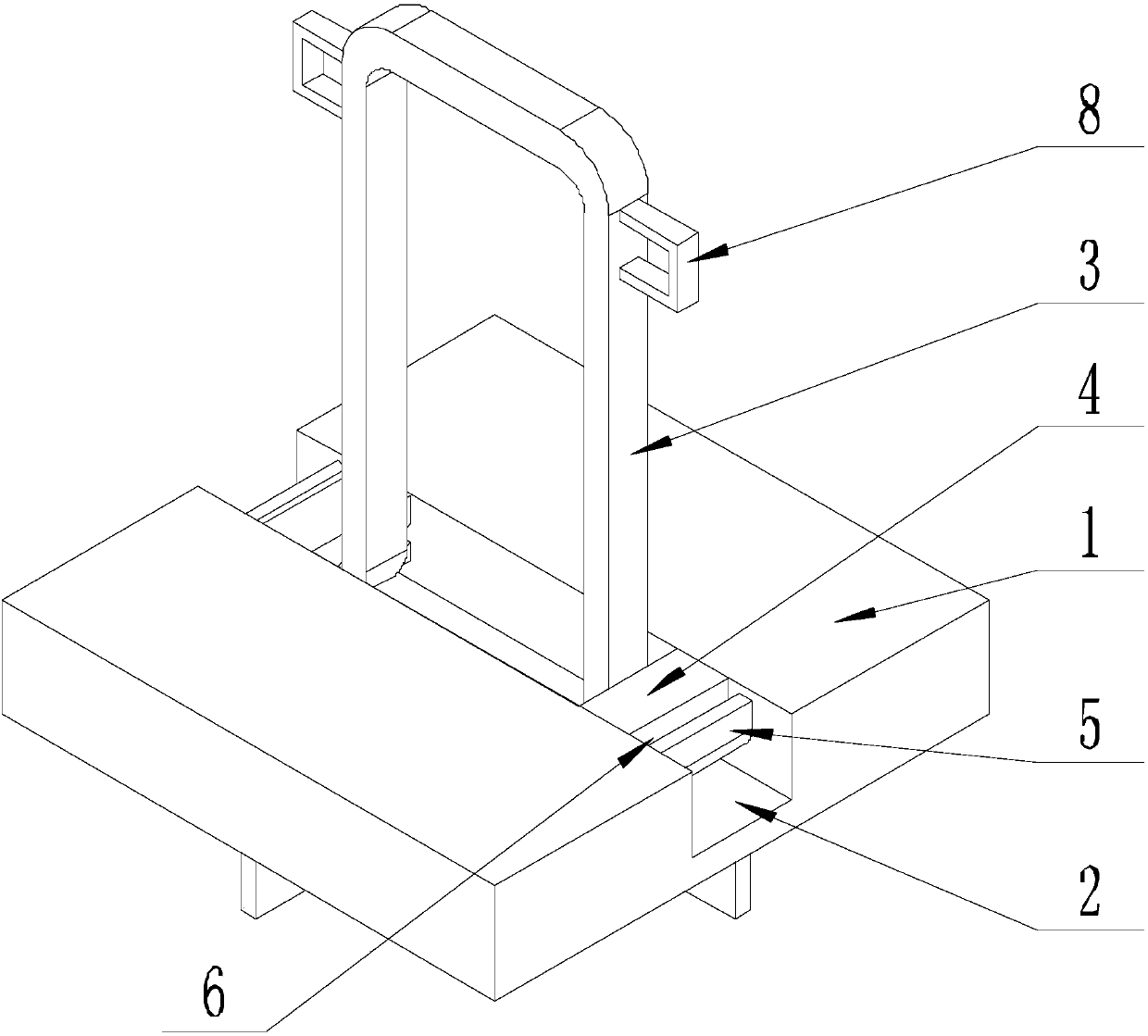

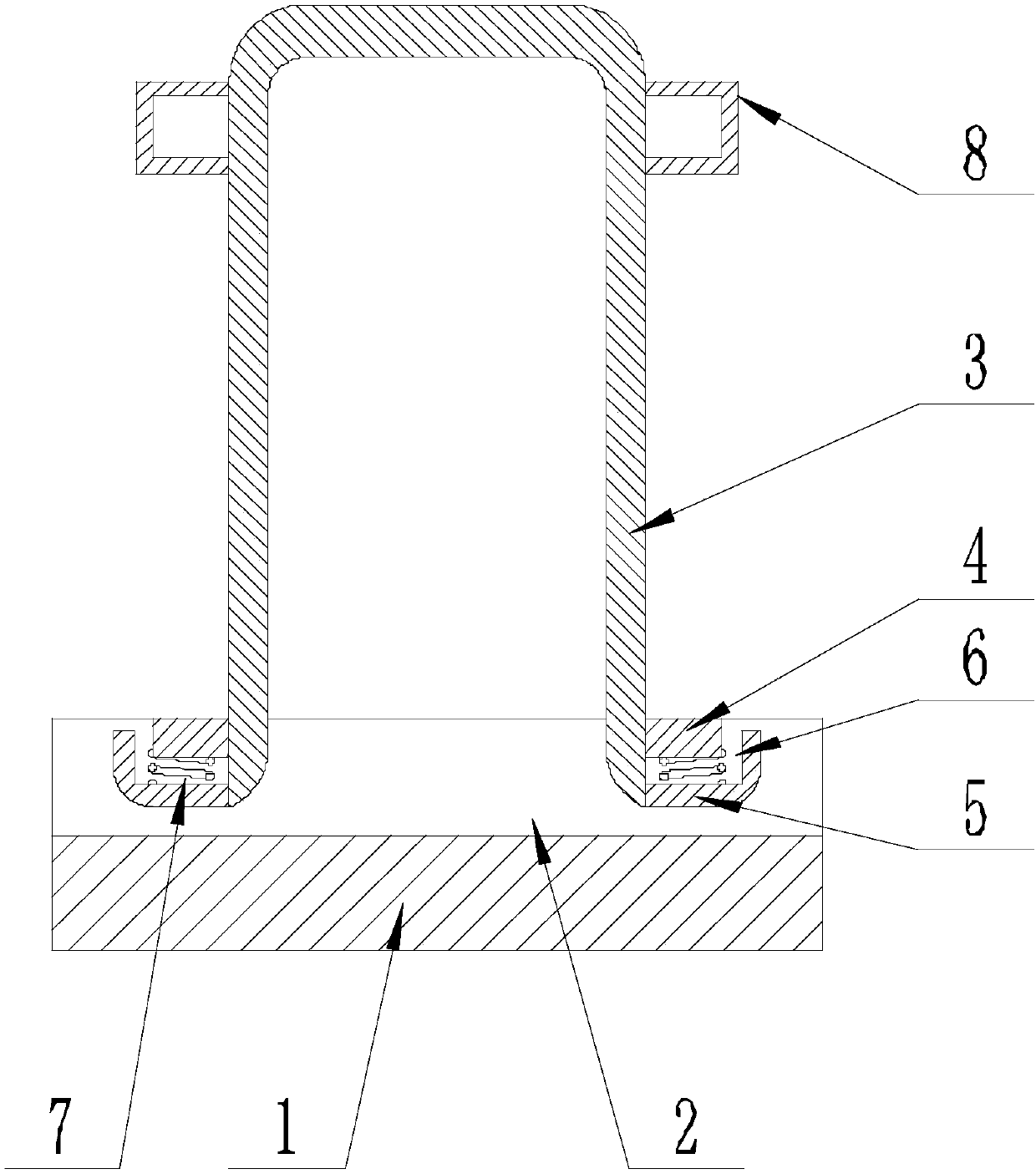

[0040] Such as Figure 1-Figure 4 Shown, the present invention improves the method for construction workers floor embossing efficiency, comprises the steps:

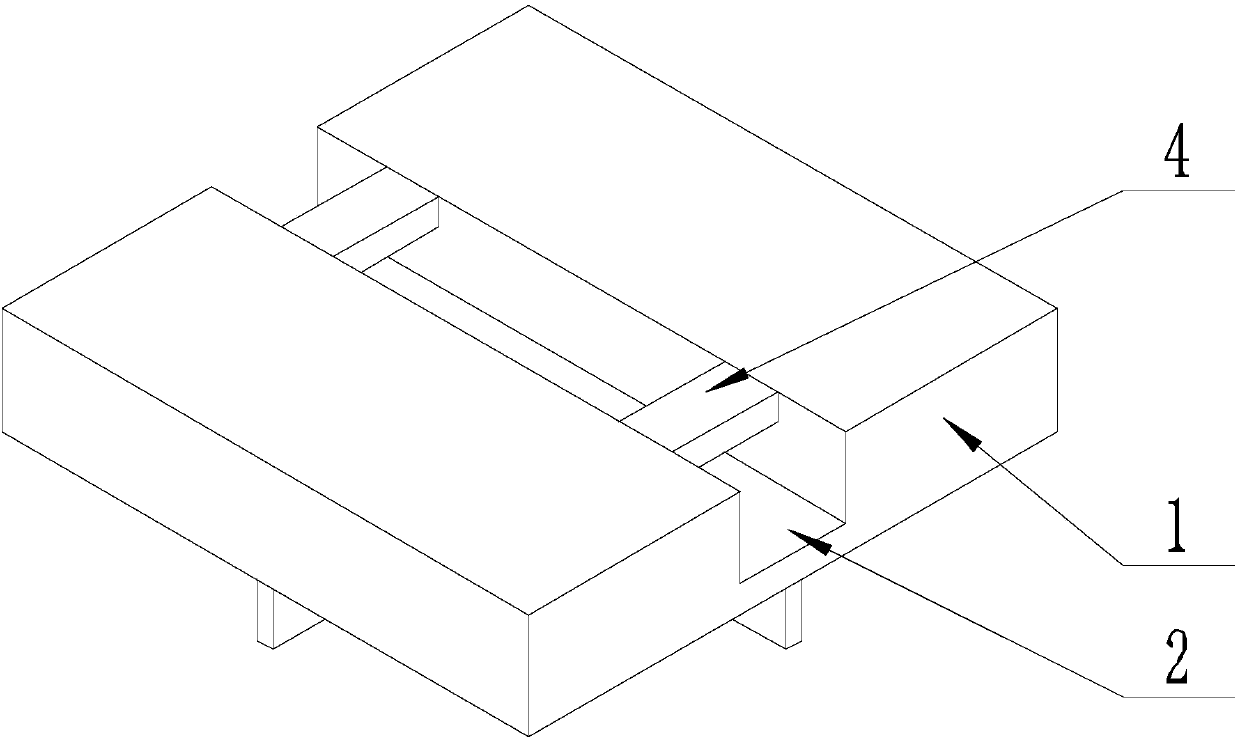

[0041] Step A: bending the lifting part 3 so that the ends of the lifting part 3 are close to each other until the maximum distance between the connecting blocks 5 at the two ends of the lifting part 3 is smaller than the minimum distance between the connecting plates 4;

[0042] Step B: Put the connection block 5 into the through groove 2, and make the ends of the connection block 5 away from the lifting part 3 respectively pass through the lower surface of a connection plate 4;

[0043] Step C: Hold the top of the lifting part 3, and move the lifting part 3 away from the embossing mold 1, so that the connecting plate 4 snaps into the connecting groove 6;

[0044] Step D: continue to move the lifting member 3 away from the embossing mold 1 to lift the embossing mold 1, and then place the embossing mold 1 on the floor w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com