A water conservancy construction device with little pollution

A low-pollution, water conservancy technology, applied in construction, infrastructure engineering, sheet pile walls, etc., can solve problems such as large vibration, high noise, and disturbing residents, and achieve the effect of improving hammering work efficiency and hammering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

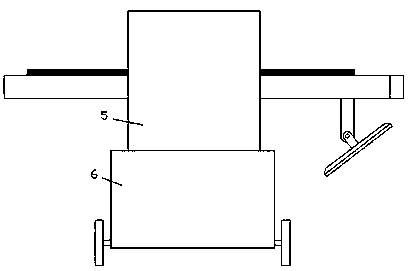

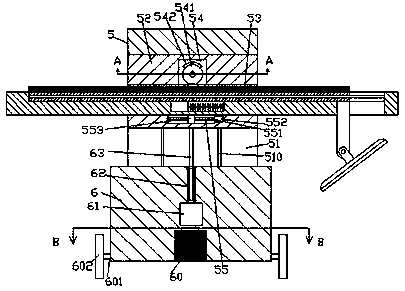

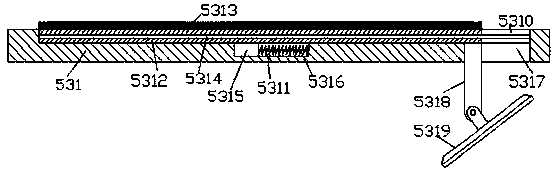

[0019] Such as Figure 1-Figure 5 As shown, a water conservancy construction device with little pollution of the present invention includes a base 6 and a hammering part 5 fixedly arranged on the top of the base 6, and a lifting and sliding groove 51 is provided in the bottom surface of the hammering part 5 , the take-off and landing sliding block 52 is slid and connected in the lifting and landing sliding groove 51, and the horizontal groove 53 extending left and right in the lifting and landing sliding block 52 is provided. part 54, the cavity part 54 is fitted with a rotating disk 541, the rotating disk 541 is provided with a toothed arc part 542, the rear side of the rotating disk 541 is connected with the first motor 543, and the first motor The outer surface of 543 is arranged in the lift-off sliding block 52 on the rear side of the cavity 54 and is fixedly connected, and the horizontal groove 53 is slidingly connected with support arms 531 extended from left to right, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com