Continuous protection structure of soil between filling piles

A technology of cast-in-situ piles and soil between piles, which is applied to sheet pile walls, foundation structure engineering, excavation, etc., can solve the problems of hidden dangers in the foundation pit support system, easy loss of soil between piles, etc., and avoid soil between piles Loss, convenient construction, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

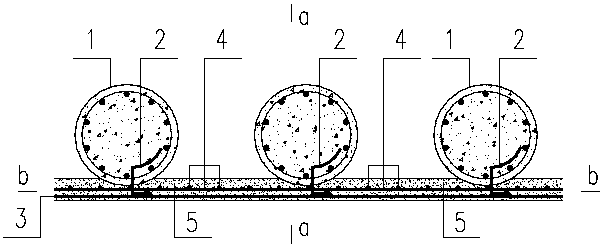

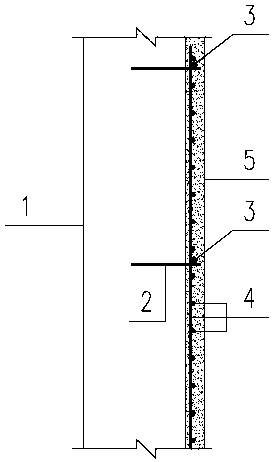

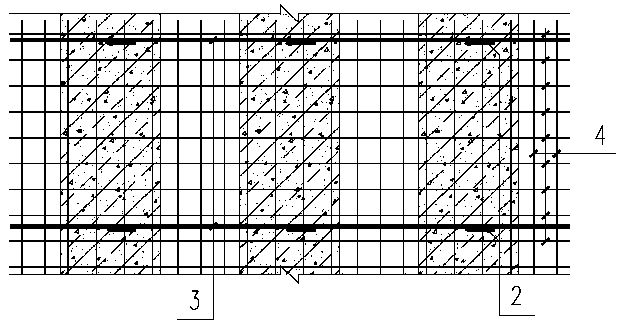

[0010] The invention avoids the loss of soil between the piles through the hanging net spraying grout between the cast-in-place piles, and utilizes continuous protection measures for the soil between the piles to ensure the safety of the support system of the foundation pit. In conjunction with the accompanying drawings, the specific description is as follows:

[0011] like figure 1 As shown, it includes cast-in-place pile 1, hanging mesh reinforcement 2, transverse reinforcement 3, reinforcement mesh 4, and concrete surface layer 5; pre-buried or planted hanging mesh reinforcement 2 in the body of cast-in-place pile 1, and one end of hanging mesh reinforcement 2 is placed The cast-in-place pile 1 is inside the pile body, and the other end is exposed outside the cast-in-place pile 1 pile body. The transverse reinforcement 3 and the reinforcement mesh 4 are arranged on the pile wall of the cast-in-place pile 1. Iron wires are used to bind and connect, and the concrete surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com