Completely-assembled metro station double-column body structure and construction method thereof

A technology for subway stations and main structures, applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve construction quality, construction efficiency, operating environment, low level of standardization, lagging development of construction technology and equipment, industrialization, and automation Low-level problems, to achieve the effect of reducing labor demand, high construction precision, reducing noise pollution and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

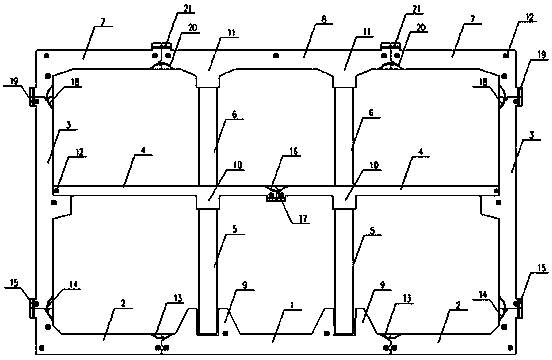

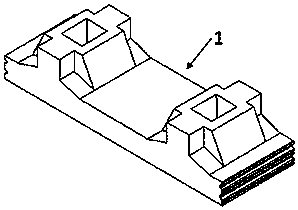

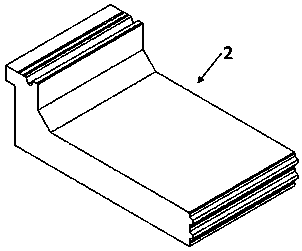

[0040] Such as Figure 1~10 As shown, a fully assembled subway station double-column main structure includes a hoisted and positioned base plate A block 1, the upper sides of the base plate A block 1 are connected to the bottom corner plate B block 2, and the bottom corner plate B block 2 are provided with a side wall C block 3, and the middle part of the bottom plate A block 1 is fixed with two lower columns Z25, and the left side middle plate D block 4 is fixed on the left side wall C block 3 and the left lower column Z25. , the right middle plate D block 4 is fixed on the right side wall C block 3 and the right lower column Z25, and the left middle plate D block 4 and the right middle plate D block 4 are all set There is an upper column Z16, and the upper column Z16 is provided with a top plate F block 8, and the two sides of the top plate F block 8 and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com