Assembled bidirectional composite wallboard and construction method thereof

A composite wallboard and construction method technology, applied in the field of construction, can solve the problems of not really meeting the green environmental protection requirements of prefabricated buildings, poor concrete compactness of post-cast connecting columns, inability to achieve thermal insulation, load-bearing integration, etc. Achieve good social and economic benefits and technical prospects, solve the problem of concrete compactness, and be beneficial to stability and earthquake resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

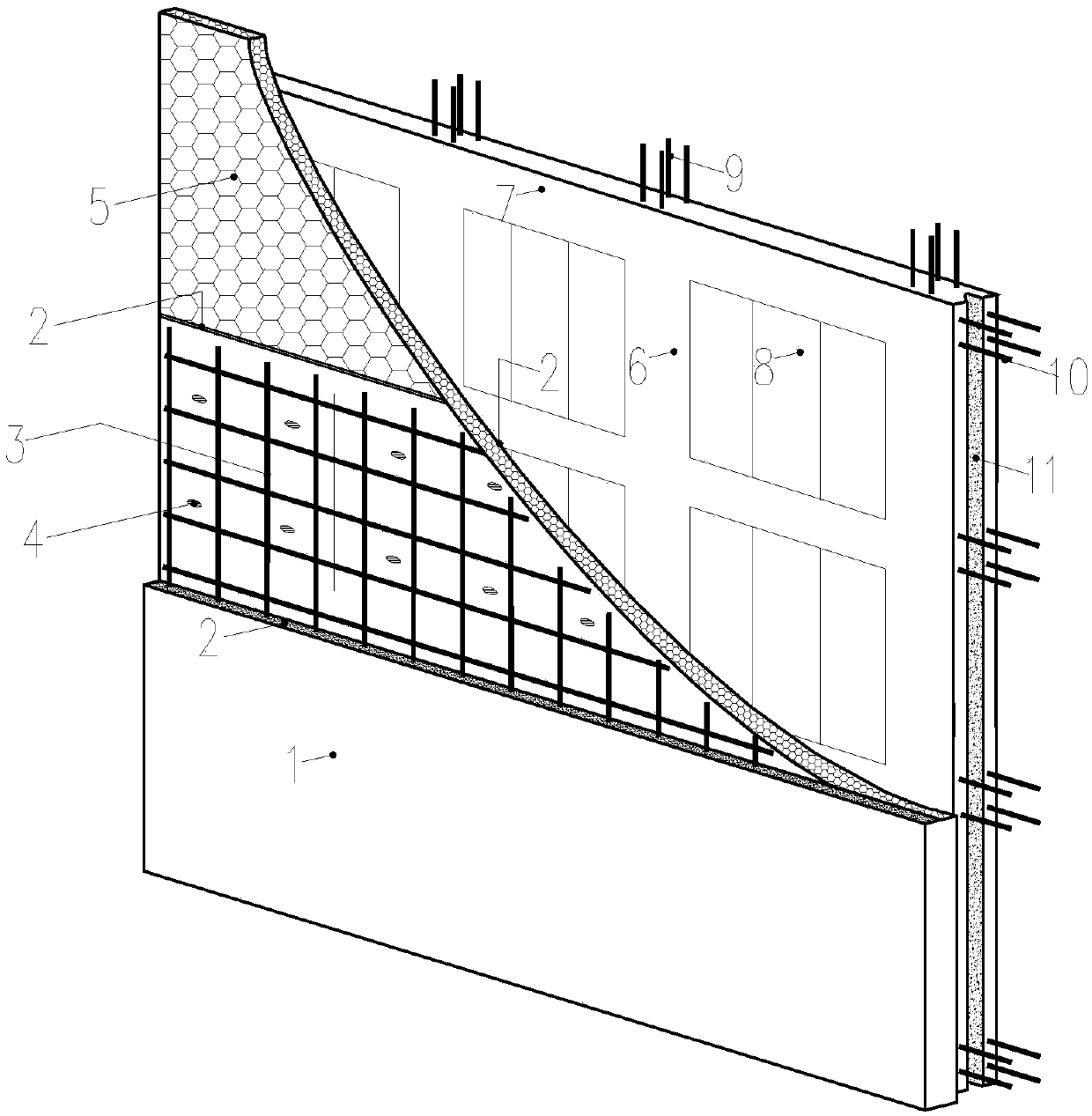

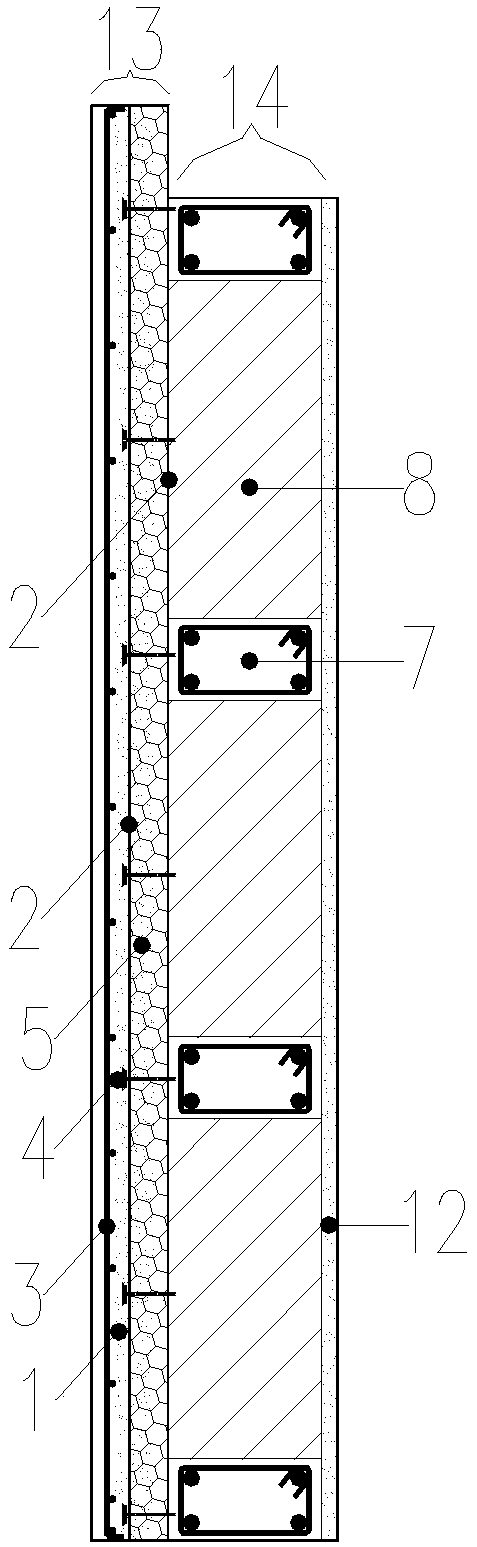

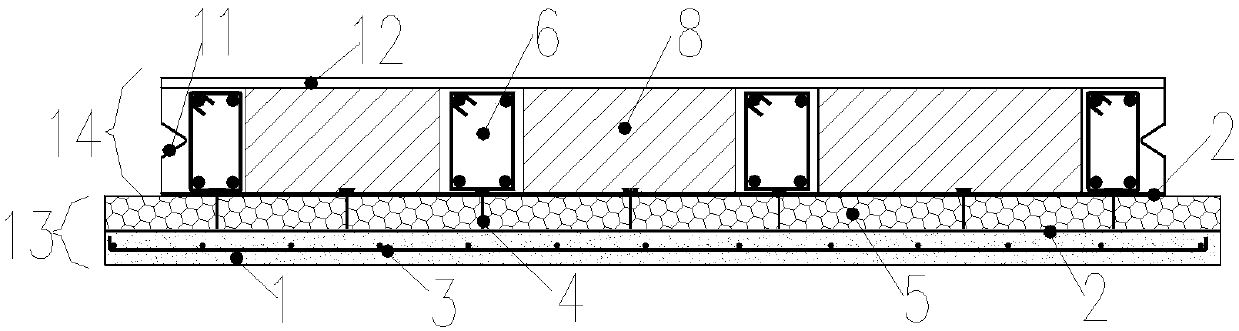

[0037] Such as figure 1 , figure 2 with image 3 As shown, the assembled two-way composite wall panel of the present invention is mainly composed of inner leaf wall panels 14 and outer leaf wall panels 13 . The inner leaf wall panel 14 is a composite wall panel mainly composed of concrete sash and autoclaved aerated concrete blocks 8, the outer leaf wall panel 13 is mainly composed of a concrete protective layer 1, XPS insulation board 5, and the inner leaf wall panel 14 and The outer leaf wall panels 13 are combined through the thermomass MS / MC connector 4 to form a thermal insulation and load-bearing integrated wall panel with in-plane and out-of-plane bidirectional compounding. It not only has the functions of thermal insulation, energy saving and load-bearing integration, but also improves the economic benefits of construction projects, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com