Split type air source heat pump system

An air source heat pump, split-type technology, applied in the field of large-scale split air source heat pump systems, can solve the problems of not too far between evaporative condensers, high energy consumption, unreliable operation at ultra-low temperature, etc., to eliminate internal interference and stabilize the system Good performance, reduce heat island effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

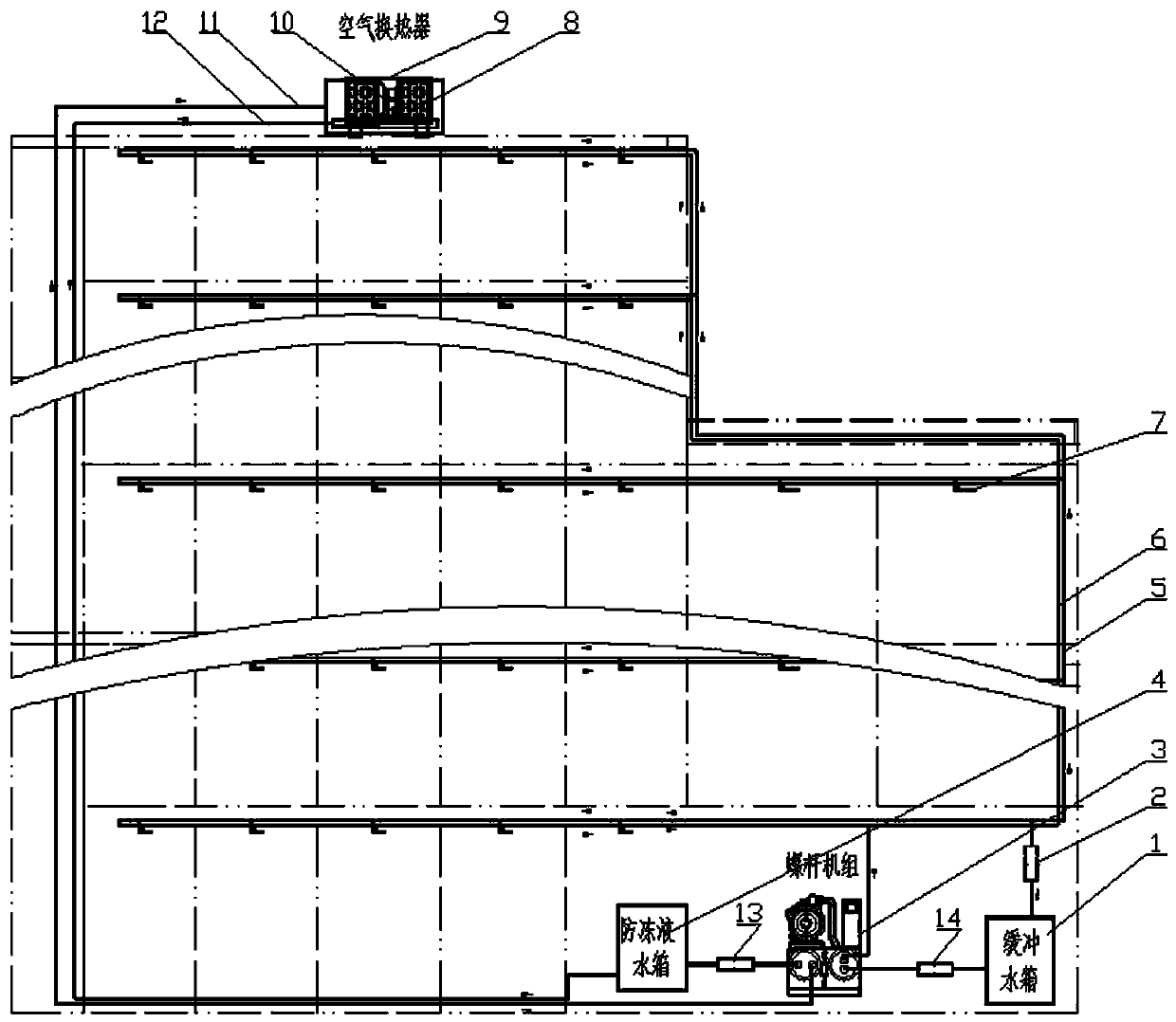

[0016] combined with figure 1 , to further illustrate the technical solution.

[0017] Such as figure 1 As shown, in the heating state: the large-scale split air source heat pump system is: arrange the air heat exchanger 8 on the roof of the building, mix ethylene glycol and water as antifreeze in a certain proportion to obtain the refrigerant A, and obtain the refrigerant A by the first A circulating pump unit 13 pumps the refrigerant A into the large air heat exchanger. Since the temperature of the refrigerant A is lower than that of the surrounding air, the large industrial fan 10 sucks the air outside the air heat exchanger from one end of the air heat exchanger. Then it is discharged from the other end of the air heat exchanger. After the refrigerant A flowing in the air heat exchanger absorbs the heat in the air flowing through the air heat exchanger, the temperature rises, and then enters the screw unit. Due to the refrigerant inside the screw unit The temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com