Optical fiber Fabry-Perot sensor welding and packaging device

A technology of Fab sensor and packaging device, which is applied in the direction of converting sensor output, using optical device to transmit sensing components, measuring devices, etc. It can solve the problems that the inner cavity of the hollow tube can not be welded with the inner cavity of the transmission fiber, etc., so as to improve the stress distribution. Effects of Uniformity, Improved Performance Stability, and Simplified Complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

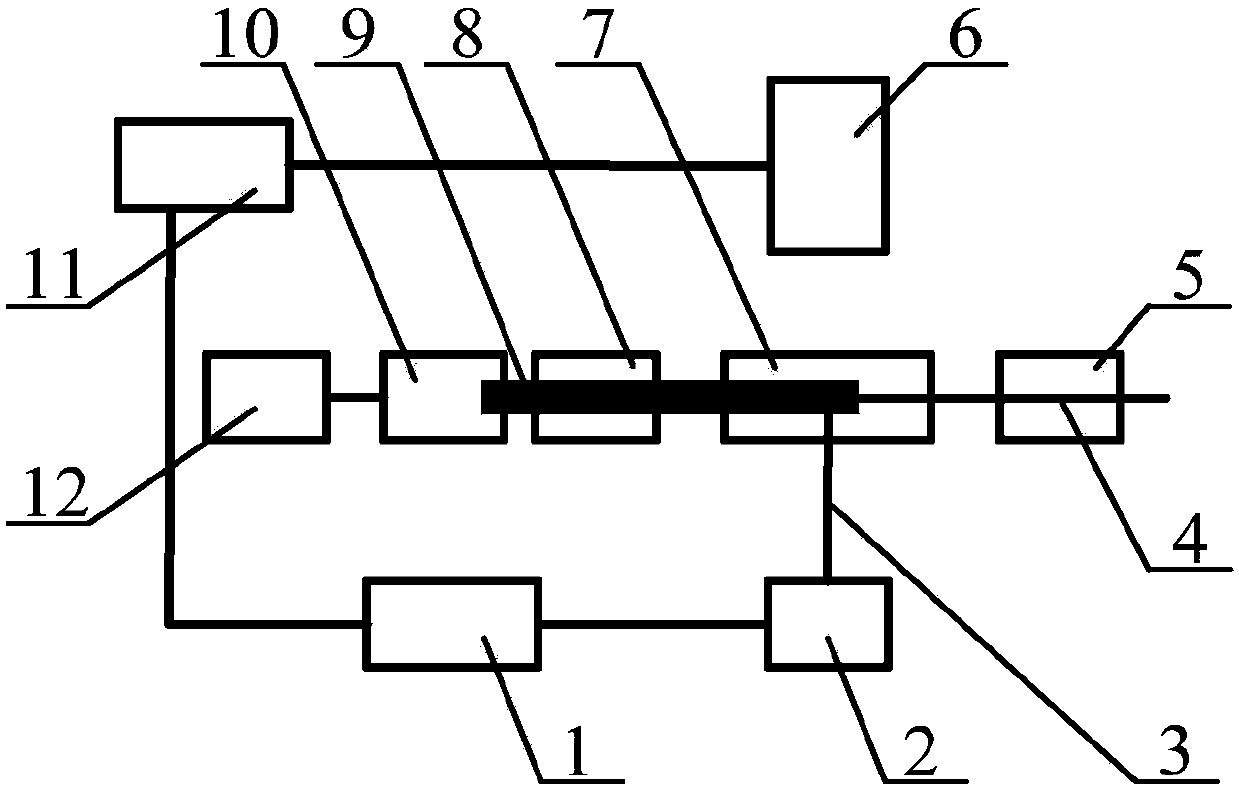

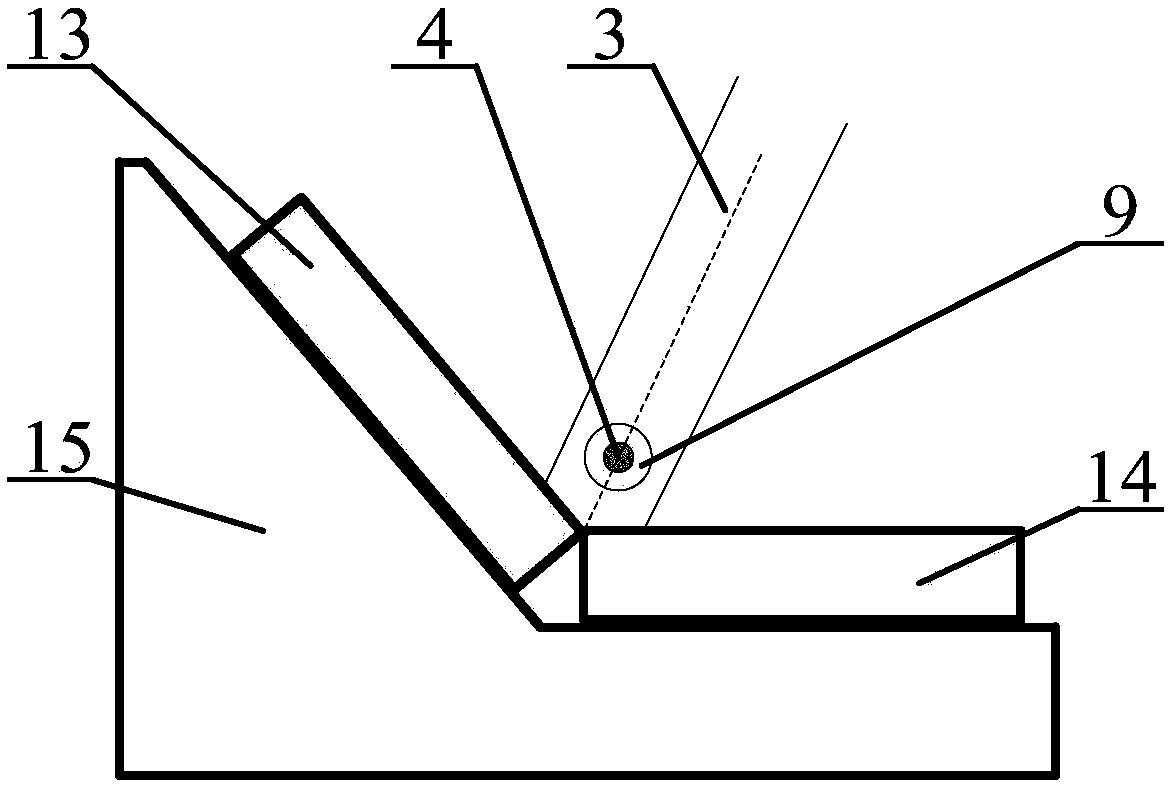

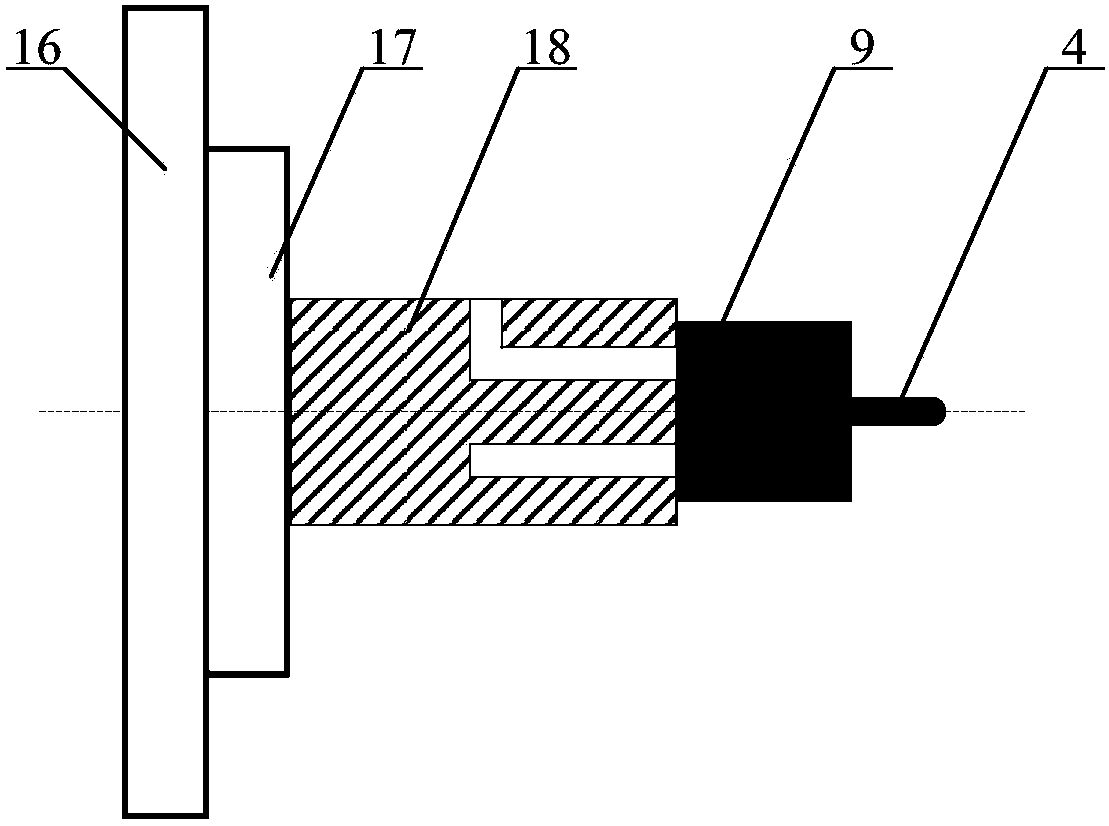

[0045] like figure 1 , Figure 4 and Figure 5 As shown, a method and device for welding and packaging an optical fiber Fab sensor, the steps of which are:

[0046] A single-mode silica fiber is used as the transmission fiber, a quartz hollow tube with an outer diameter of 2 mm and an inner diameter of 130 μm is used as a cylindrical hollow tube, and a manual rotating table is used as a rotating fixture. The transmission fiber holder 5 horizontally clamps the single-mode quartz optical fiber 19, and the hollow tube holder 8 horizontally clamps the quartz hollow tube 20; as image 3 As shown, the adsorption rotary device 10 is composed of an adsorption fixture 18, a rotary fixture 21 and an adsorption rotary bracket 16. The two fixtures are coaxially installed on the adsorption rotary bracket 16, and the end surface of the adsorption fixture 18 is in close contact with the end of the quartz hollow tube 20. can achieve reliable adsorption; figure 2 Shown, reflecting mirror ...

Embodiment 2

[0051] like Image 6 shown, based on Example 1 Figure 4 Schematic diagram of the device, the light source 24 is connected to the input end of the circulator 22, the output / return end of the circulator 22 is connected to the single-mode quartz fiber 19, and the output end of the circulator 22 is connected to the spectrometer 23. A spectrometer 23 is used to monitor the loss of transmitted light energy during the fusion splicing process to judge the splicing quality of the single-mode quartz optical fiber 19 and the quartz hollow tube 20 .

Embodiment 3

[0053] like Figure 7 As shown, the embodiment 1 Figure 5 The manual rotating table 21 in the present invention is replaced by an electric rotating table 25, and controlled by a computer 11, the ring-shaped welding packaging of the single-mode quartz optical fiber 19 and the quartz hollow tube 20 is automatically realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com