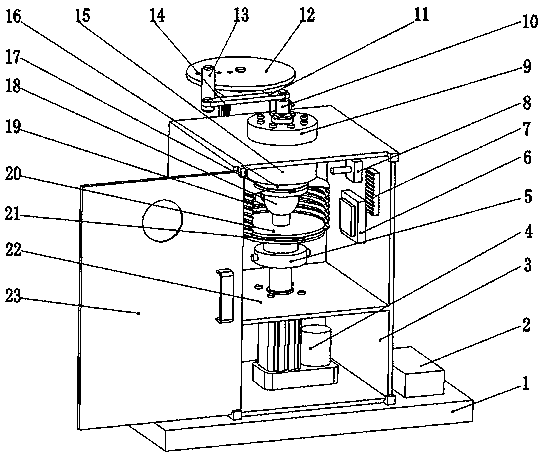

Hip joint prosthesis friction wear testing machine

A friction and wear test, hip joint prosthesis technology, applied in the direction of testing wear resistance, etc., can solve the problems of difficult realization of equipment, test errors of hip joint prosthesis specimens, etc., to achieve accurate and objective test results, low cost, Control easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

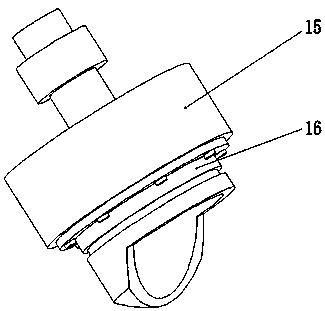

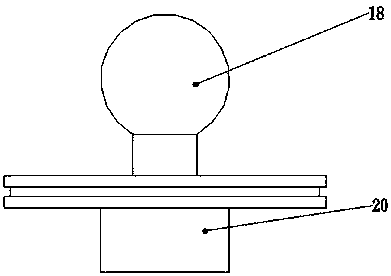

[0022] refer to Figure 1-Figure 4 , the hip joint prosthesis friction and wear testing machine provided in this embodiment includes a base 1 and a test box 3 installed on the base 1, and the test box 3 is divided into an upper cavity and a lower cavity by a box partition 22 Body, the servo electric cylinder 4 is installed in the lower chamber, the output shaft of the servo electric cylinder 4 passes through the through hole of the box partition 22 and is fixedly connected with the bottom end of the pressure sensor 5 arranged in the upper chamber, and the top end of the pressure sensor 5 is fixedly connected. Connect the lower test piece mounting seat 20, the top of the lower test piece mounting seat 20 is screwed to the joint head test piece 18; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com