Twist-beam axle for electrically driven motor vehicle

A technology for motor vehicles and torsion beams, applied in electric power units, power units, steering mechanisms, etc., can solve problems such as the height difference between the center of gravity and the roll center of motor vehicles, achieve a small turning circle, improve flexibility and maneuverability, The effect of good mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

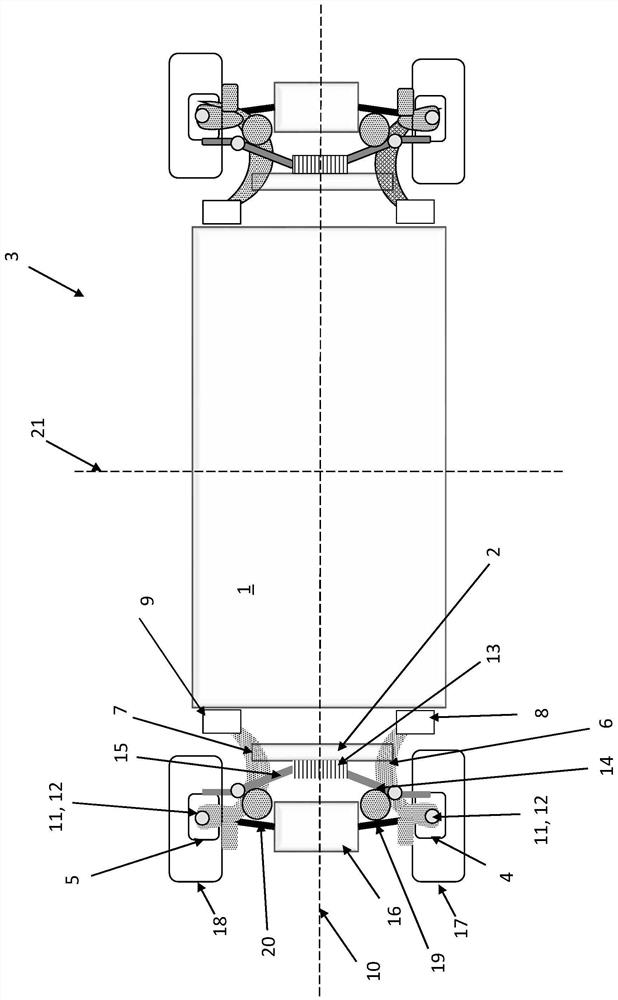

[0024] the only attached figure 1 A plan view is shown of a battery tray 1 of a motor vehicle 3 driven by means of an electric motor 16 and having a torsion beam axle according to the invention arranged thereon. here, in figure 1 In the illustration of , only the left-hand torsion beam axle is provided with reference numerals, since the right-hand torsion beam axle is correspondingly only designed as a mirror image of the left-hand torsion beam axle.

[0025] Here, the torsion beam axle essentially consists of two longitudinal links 6 and 7 , which are connected to one another via a cross member 2 . The transverse beam 2 is designed here as a bending-resistant and torsion-flexible torsion profile. The longitudinal links 6 and 7 are arranged on the battery tray 1 and connected to it by means of rubber bearings 8 and 9 . At their ends opposite the rubber bearings 8 and 9 , the longitudinal links 6 and 7 have wheel carriers 4 and 5 , on which wheels 17 and 18 can be respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com