Full-automatic headspace sample injector mechanism and control method

A headspace sampler and control method technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of increasing system cost and high price of automatic headspace sampler products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

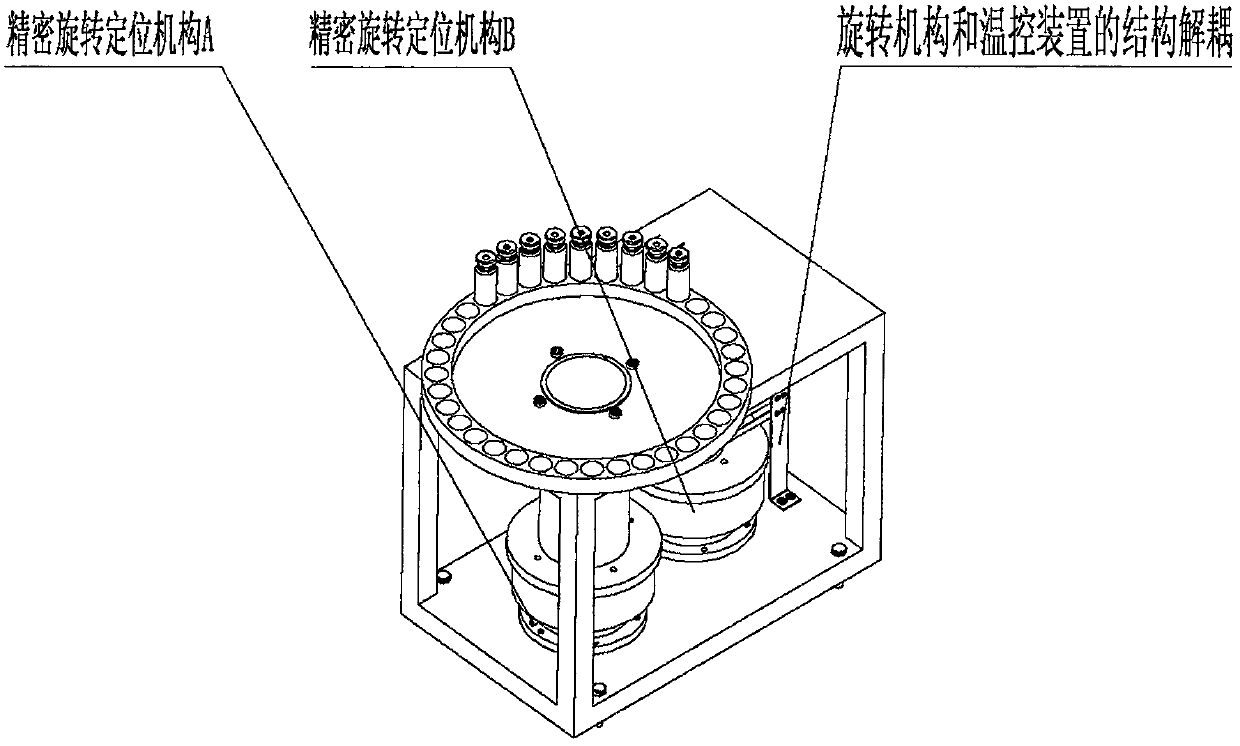

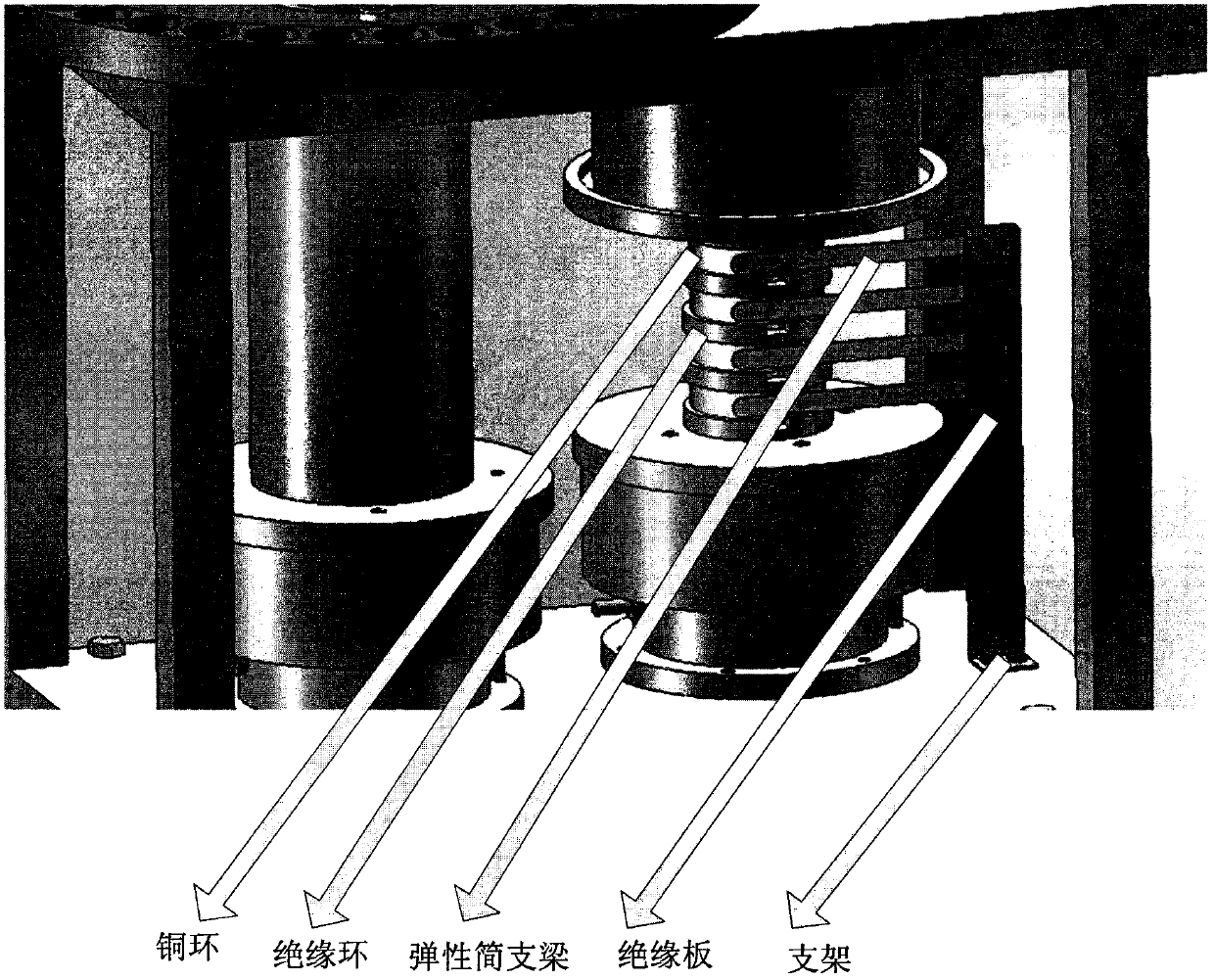

[0024] 1. Executive body

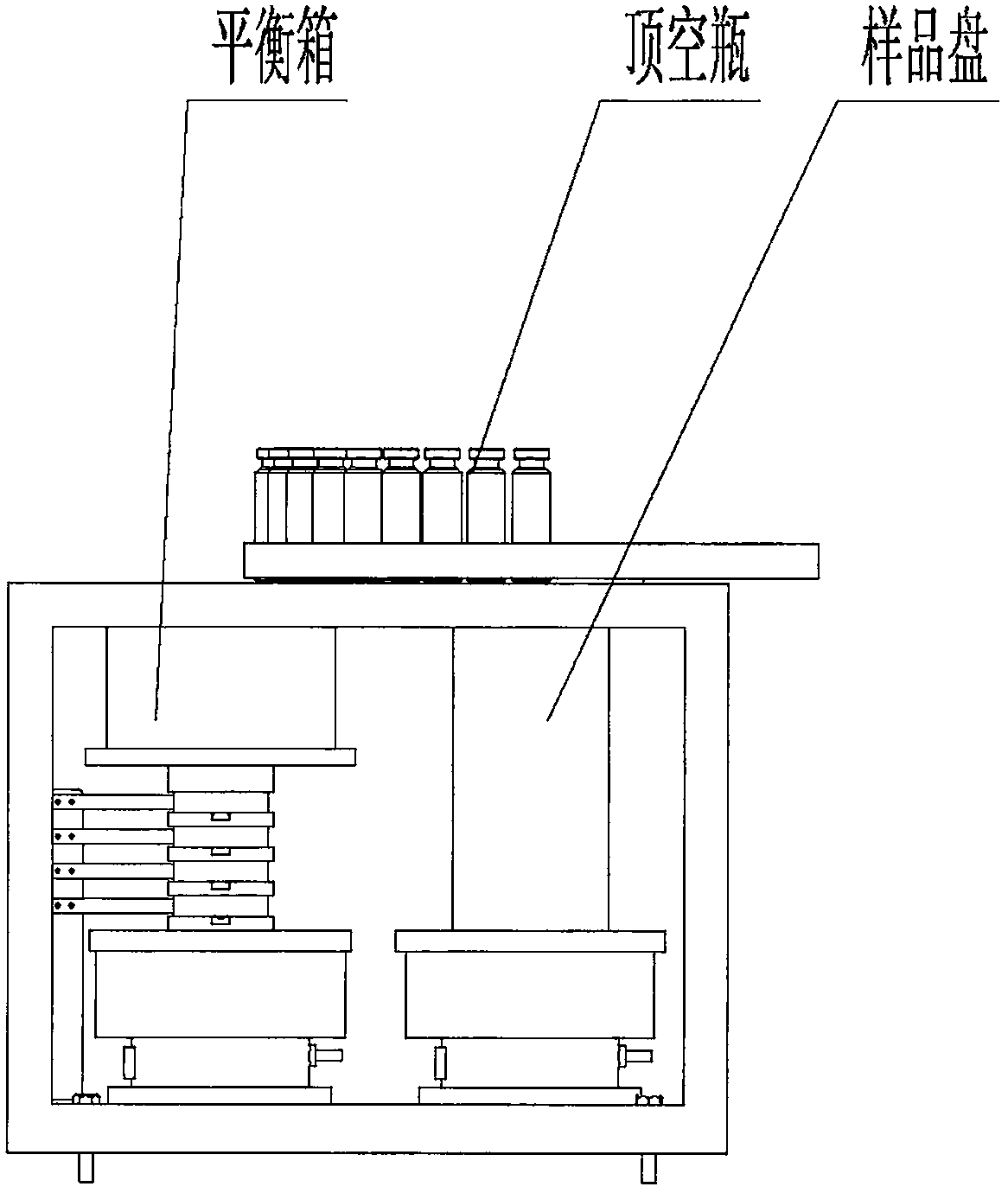

[0025] (1), the precision rotary positioning mechanism A comprises a stepper motor, a driver, a reducer, a sample tray holder, and a sample tray that can place 36 headspace vials. The selection of the stepper motor, driver, and reducer is shown in Table 1, and the sample tray bracket and sample tray are self-made.

[0026] Table 1

[0027]

[0028] (2), the precision rotary positioning mechanism B comprises a stepper motor, a reducer, a balance box bracket, and a balance box that can place 9 headspace bottles. Among them, the selection of stepper motor, driver, and reducer is shown in Table 2. The balance box bracket and the balance box are self-made.

[0029] Table 2

[0030]

[0031] (3) The relative position of precision rotary positioning mechanism A and B should be able to achieve the alignment of the balance box hole and the sample plate hole, to ensure that the headspace bottle can accurately fall into the balance box according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com